-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

How Construction Companies Save 20% Fuel Costs with TrackoBit’s Fuel Monitoring

- Author:Anvesha Pandey

- Read Time:5 m

- Published:

- Last Update: August 19, 2025

Table of Contents

Toggle

Wondering how construction companies are slashing fuel costs and boosting profits with smart fuel monitoring solutions? Read this blog to get your “HOW “answered.

Table of Contents

ToggleFuel costs can comprise 30%-50% of a construction project’s total operating expenses. Plus, with rising prices, the burden only grows heavier. From excessive idling & inefficient routes to undetected diesel theft, construction companies lose “LAKHS” every year without even realizing it.

What if you could cut those fuel costs by 20% or more? Sounds impossible, right? It’s not! With the right visibility and control, it’s totally achievable. The solution?

Fuel Monitoring Software! In fact, its real-time tracking and data-driven decisions are all you need.

Explore how construction businesses are turning the tide on fuel wastage.

Common Fuel Cost Headaches in Construction!

Fuel keeps construction fleet uptime high, but it also leads to huge costs if not managed well. Not having proper hands-on tracking, fuel gets wasted through idling, misuse & sometimes even theft.

Here’s an overview of where companies bleed fuel-

Headache 1 – Idling & Over speeding

Construction vehicles often idle for long periods during loading, waiting, or minor delays. This leads to burning fuel without moving an inch. Over speeding on-site or between sites leads to faster consumption and increases heavy equipment or vehicle wear and tear.

Read More: How to Reduce Idle Time of Your Fleet

Headache 2 – Fuel Pilferage

Without real-time vehicle tracking, fuel theft whether during refueling or directly from vehicle tanks, it can easily go unnoticed. Even small, regular pilferage across a fleet adds up to huge losses.

Headache 3 – Poorly Planned Operation

Unorganized trips, inefficient vehicle routes between sites, and last-minute changes force construction vehicles to run extra miles. This results in wasting both gas and production time.

Headache 4 – Lack of Actionable Data

Without live tracking and detailed reports from each vehicle, you are left guessing about usage patterns and wastage. Additionally, a lack of data delays corrective actions and also inflates operating costs.

Given these industry’s challenges, an effective fuel monitoring system is a must for construction. Now, let’s dive into how TrackoBit makes a difference.

How TrackoBit’s Fuel Monitoring Software Changes the Game?

Fuel management isn’t just about tracking consumption. It’s about taking control of every aspect of operations across the entire fleet. Here’s everything that you enjoy with TrackoBit’s fuel management system:

1. Live Monitoring

The wastage often starts with a lack of visibility. TrackoBit with fuel management software allows you to monitor diesel levels in real-time for any vehicles or heavy machinery you use during your contracts.

Here’s the fuel monitoring software how it helps

- Prevent Overflows: It helps make sure gas deliveries align with actual needs, preventing overfilling and cutting down on waste.

- Spot Discrepancies Early: Smart alerts and notifications flag any sudden drop in levels instantly. This helps you catch and resolve issues before they turn costly.

- 24/7 Monitoring: Track the onsumption anytime, anywhere, ensuring that no drop goes unaccounted for

2. Instant Refill & Drainage Alerts

Theft or misuse is a common issue in large fleets, but with TrackoBit’s system, you’ll be immediately alerted whenever diesel is added or drained from your vehicles.

How it helps

- Stop Theft in its Tracks: Instant alerts for any unexpected draining or refilling help you identify theft or unauthorised activities immediately.

- Enforce Accountability: Ensure transactions are tracked and properly documented.

Related – 10 Ways How Fuel Cards Helps Save Money

3. Idle Time Tracking

Excessive idling is one of the biggest contributors to unnecessary consumption in construction fleets. The software tracks idle times and vehicle engine status in real-time.

How it helps

- Reduce Idle Times: Get data on how long vehicles are idling, directly impacting fuel consumption.

- Improve Efficiency: Take action to cut down on idle time by scheduling equipment use and minimizing unnecessary delays.

- Save Fuel & Time: Reduce the number of hours spent idling and ensure equipment is only running when necessary, resulting in significant savings.

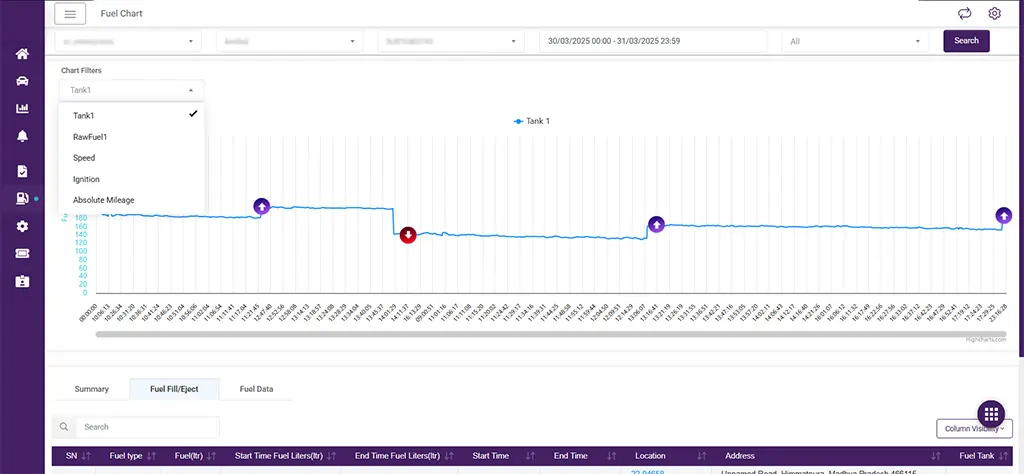

4. Smart Consumption Reports

Fuel monitoring software doesn’t just collect data it transforms it into actionable insights. The software generates detailed reports on usage, trends, and inefficiencies across your fleet.

How it helps

- Detailed Analytics: Access comprehensive reports that break down usage by vehicle, time, location, and driver.

- Identify Fuel Wastage: Spot trends and irregularities to identify where gas is being wasted, whether through poor routes, idling, or driving habits.

- Plan Smarter Operations: Use the data to optimize gas usage, improve scheduling, and reduce unnecessary trips, ultimately driving cost savings.

Let’s dissect the case of a leading infra construction company that solved its

That’s how Fuel Reports Appear!

💰 A Case Study of Leading Infrastructure Construction Company

A Case Study

The Client Profile

A leading infra-Construction, established in 2010 with a strong presence across LATAM regions approached us with some problems.

The Problem

The company started scaling up their projects, they quickly ran into a serious problem — fuel costs were spiraling out of control. Despite spending thousands every month, they had no real visibility into where the fuel used was going.

Idling, misuse, and suspected pilferage were common complaints, but without solid data, it was impossible to fix.

Their Challenges

Solution We Helped Deliver

That’s when they decided to implement TrackoBit’s Fuel Monitoring Software across their fleet of earthmovers, trucks, and site vehicles.

–> Within a week, they had real-time visibility into fuel levels, idling patterns, and suspicious routing patterns & idling activities.

–> Custom alerts helped them spot unnecessary idling and unauthorised fuel drainage, while detailed reports made it easier to hold drivers and site managers accountable.

Here’s How TrackoBit Helped

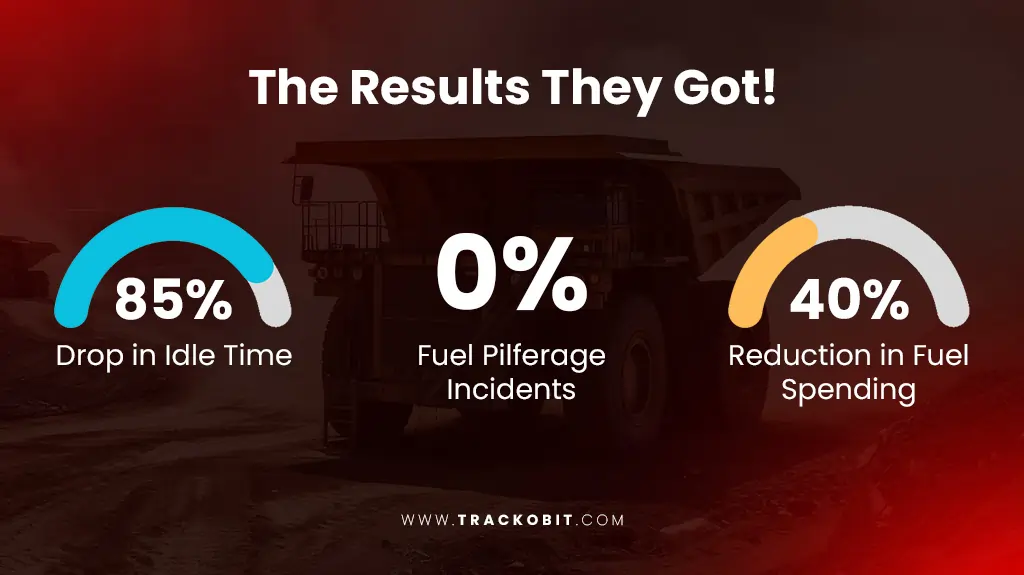

The Results They Got!

Within just 3 months, This Mega Construction giant saw real change with the help of fuel management software:

- Idle time dropped by 85%.

- Fuel pilferage incidents went down to 0.

- Overall undisputed fuel spending reduced by 40%.

And the best part? They didn’t just save money with the fuel monitoring software. But they also built a culture of accountability and smarter operations across their projects.

The Result They Got!

Final Words

Okay so at the end of the day, construction fuel monitoring software isn’t just an option anymore. Infact it is the smart way forward. With all the benefits it brings to the table, software is something that can transform your operations.

So, are you ready to transform your fleet & gas for the growth of your business with fleet management software?

If you’re serious about cutting costs, boosting efficiency, and scaling smarter, it’s time to make the switch.

With TrackoBit’s Construction Fuel Management Software, you don’t just manage, you optimise every mile, every drop of gas, and every working hour.

The result? Safer fleets. Happier clients. A business that outpaces the competition.

Talk to our experts today!

FAQs

-

How can the construction industry lower its gasoline expenses?

By combining real-time fuel monitoring, driver training, route planning and strict fuel management practices.

-

How quickly can construction companies see ROI using fuel monitoring solution?

Many companies start seeing measurable savings and returns within just 2–3 months of implementation.

-

Is fuel monitoring effective for heavy construction equipment?

Yes, it provides accurate real-time data to track usage, reduce wastage, and improve overall fuel efficiency.

-

How does GPS-based fuel monitoring reduce operational costs?

By planning routes, reducing idling, preventing theft, and providing actionable insights for smarter fleet management.

Anvesha is a communication specialist at TrackoBit. With a strong background in media and communications, she adds much-needed balance and brevity to TrackoBit’s... Read More

Related Blogs

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

-

How to Use Driver Behavior Reports as a Sales Hook to Close Big Fleets

Tithi Agarwal October 16, 2025TrackoBit’s driver behavior reports empower fleet providers to win big contracts by showcasing safety, efficiency, and measurable ROI.

-

TrackoBit’s Unlocking in Geofence with OTP: Elevating Cargo Protection

Tithi Agarwal September 16, 2025TrackoBit’s latest feature – Unlocking in Geofence with OTP lets you lock out theft and unlock cargo only at the…

-

The Rise of Electric Fleets: Challenges and Opportunities for Businesses

Tithi Agarwal September 4, 2025The global fleet landscape is poised for a decade-long transformation. This change is being powered by electricity. Logistics-led businesses are…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.