-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

How to Reduce Idle Time of Your Fleet?

- Author:Anvesha Pandey

- Read Time:6 min

- Published:

- Last Update: February 10, 2025

Table of Contents

Toggle

Vehicle Idling doesn’t just drain your fuel costs- it’s also harmful to the environment. Unfold practical strategies for minimizing idle time & boosting efficiency in this insightful read!

Table of Contents

Toggle

Excessive idling is silently draining your fleet. While idling cannot be entirely avoided, it can spiral into a destructive habit if left uncontrolled.

Contrary to popular belief, turning off and restarting a vehicle consumes less fuel than letting it idle.

However, fleet managers fail to notice when their vehicles are idling, resulting in unnecessary fuel loss, compounded repair costs, and even hefty fines in some regions.

But the good news?

With the right strategies, you can significantly reduce idle time, enhance fuel efficiency & save costs.

This piece explores practical steps to reduce idle time & maximize the efficiency of your fleet.

What is Idle Time?

Idle time can also be referred to as vehicle idling. It is basically the amount of time when the vehicle’s engine is running, but then the vehicle itself is in its stationary position.

There are various reasons for engine idling such as maintaining cabin temperature, onboard equipment, or at times out of habit. However, prolonged idling results in unnecessary fuel consumption, increased emissions & engine wear.

One reliable way to detect vehicle idling is by monitoring the engine’s RPM (Revolutions Per Minute).

Under normal driving conditions, the engine typically operates within a range of 1,500 to 3,000 RPM. This might depend on the vehicle & the driving situation).

However, when a vehicle is idling, the RPMS drops significantly, as the engine is running without propelling the vehicle forward. Idling RPM usually falls between 600 & 1,000 RPM, depending on the vehicle type.

| 💡Did You Know?

Idle time beyond 30-60 minutes per trip or 15-20% of total operational hours leads to fuel wastage, higher costs, and reduced efficiency. |

How To Reduce Idle Time For Fleets? (Top 4 Ways)

1. Monitoring Idle Time with Telematics

Vehicle telematics systems play a very crucial role in minimizing fleet idle time. The system offers you features like real-time tracking, automated alerts & advanced analytics. It monitors engine run, RPM fluctuations & fuel consumption to detect engine idling.

You can leverage the idle reports, and geofencing alerts to pinpoint inefficiency. Further, these insights enable you to implement better decision-making.

Additionally, you can set alerts for prolonged idle time. This will help you optimize the route, followed by allowing you to make data-driven decision-making to enhance efficiency & cut fuel costs.

2. Use Automatic Engine shut-off Features

One of the easiest ways to reduce idle time is by taking advantage of the automatic engine shut-off features. This feature is usually found in modern vehicles. Essentially, these features automatically turn off the engine after a set period of idling (which helps prevent unnecessary wastage of fuel).

In fact, it’s an effortless way to ensure your vehicles aren’t running when they don’t need to be.

3. Train Drivers on Idling Reduction Techniques

Undoubtedly, the human element is just as crucial as the technology. The driving patterns of drivers can really impact fleet efficiency. You can educate drivers about fuel-efficient driving techniques. These techniques could be maintaining steady speeds, minimizing abrupt acceleration & harsh braking.

Additionally, these training programs help emphasize eco-driving techniques that benefit the environment. It also contributes to the longevity of vehicles, reduces maintenance costs over time & decreases the consumption of fuel in the longer run.

4. Optimize Route Planning & Trip Management

Effective route planning is very essential for fleet-centric businesses. This is where an ideal route planning software comes into play. The software allows you to manage trips, define optimal routes & track them in real-time. It allows you to set & track the most efficient routes that avoid as many idling zones as possible.

Route planning system with inherent GPS technology goes beyond just finding the best path from point A to B. It also provides deep insights into past trips. This helps to develop an understanding of the routes previously traveled & gauge the pattern of fuel consumption and idle time trends, so efficient routes can be picked or poor habits can be gauged.

What are Some of the Most Common Reasons For Idling?

1. Traffic Delays & Congestion

Traffic congestion is one of the most significant contributors to idling. In urban areas, traffic jams can force vehicles to stop & start frequently, leading to long periods of idling.

According to the U.S. Department of Energy, traffic congestion alone accounts for up to 30% of total idling time in urban areas. While stuck in traffic vehicles continue to burn fuel without making any progress. This further accounts for wasted fuel & increased emissions.

Drivers may not be able to avoid this idling. However, you can work to schedule routes during times of lighter traffic or use advanced fleet management tools to help reroute vehicles in real-time to avoid congestion.

2. Waiting for Cargo Loading & Unloading

Idling is also common when waiting to load or unload goods. The wait time for loading & unloading consignments can often be unpredictable & vehicles are left idling.

For example- Delivery trucks waiting for warehouse workers to load or unload their cargo can be left running for hours.

3. Driver Habits & Comfort

Fleet driver habits play a big role in the amount of time a vehicle is idling. Many drivers leave their engines running even when making short stops. Reasons could be to take a rest from driving, wait for customers to arrive, or who knows what else.

Well, mostly this is done to enjoy extra hours of breaks in air conditioning. However, this has to be looked into. Leaving the engine running for personal comfort to a limit is fine. But going beyond the justified period calls for serious intervention. As this costs you unnecessary fuel consumption & costs.

According to the U.S. Environmental Protection Agency (EPA), just 5 to 10 minutes of idling can waste up to 0.8 gallons of fuel.

4. Cold Starts

Cold starts, particularly in colder climates, are another reason for excessive idling. During winter, drivers may leave their vehicles idling to prevent the battery from draining or to warm up the engine before driving.

This practice generally wastes a considerable amount of fuel, especially in older vehicles.

Newer vehicles are typically better equipped to handle cold starts with minimal fuel consumption, so the need for extended idling is significantly reduced.

You can invest in driver training programs to teach proper cold-start techniques. Further helping to reduce idle time in colder months.

Have a look into some stats!

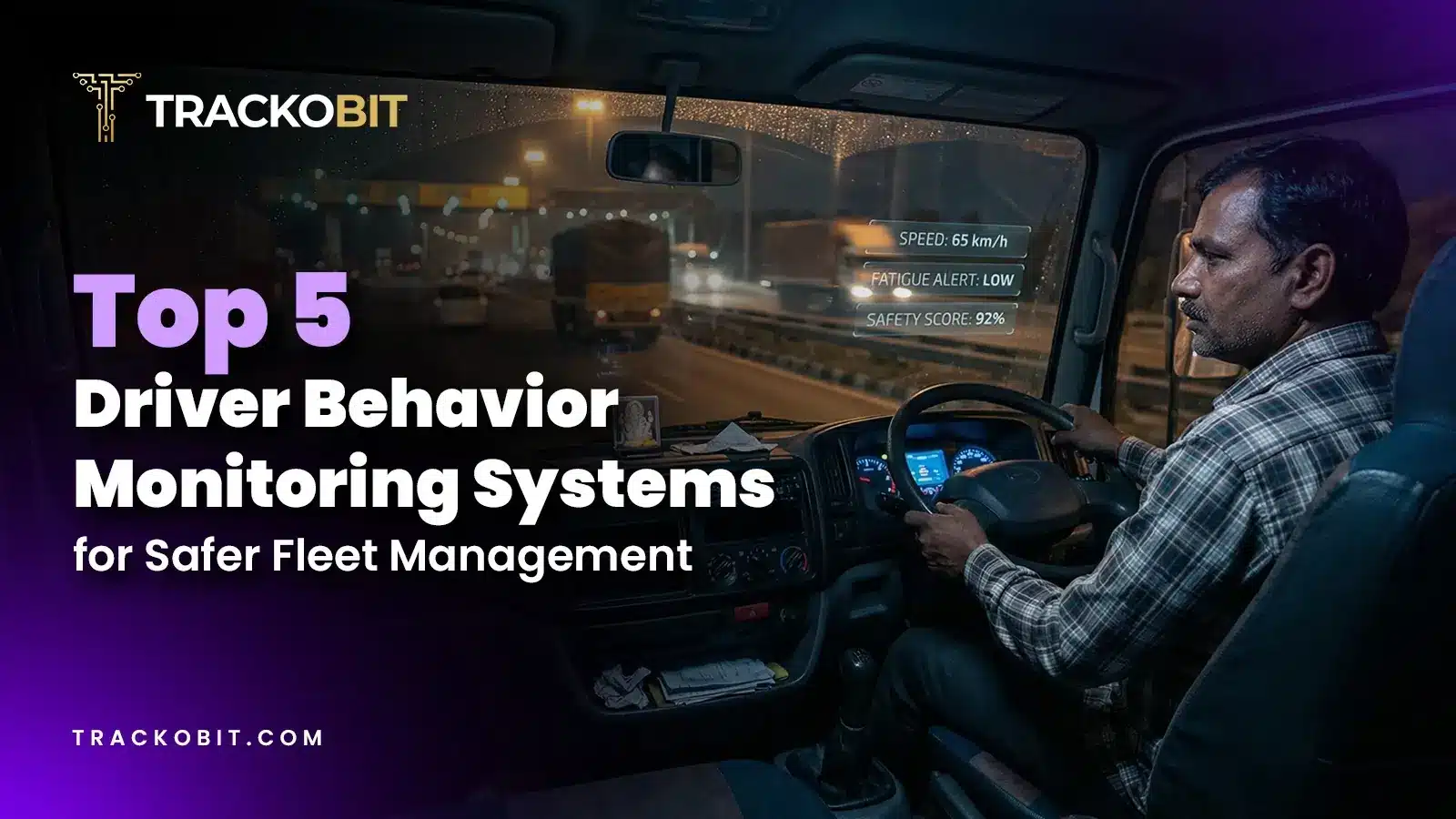

Train Drivers Well With Data from Driver Behavior Management System

Driver behavior management system helps you track idling patterns & identify drivers who need training. The system allows you to analyze driving data.

Analyzing this driving data facilitates targeted coaching (such as instructing drivers to turn off the engine during short stops.)

The software also generates reports on harmful driving habits, improving overall fleet efficiency and engine health.

Here’s what all you get.

1. Look Out For ‘Idle Zones’ Through Real-time Tracking and Monitoring

Real-time tracking and monitoring have become essential tools for fleet managers who need to keep their vehicles moving efficiently and effectively. They can help fleet managers identify idle zones. And this is important because idle zones can easily be avoided with better supervision and training.

But if left unresolved, they lead to increased fuel consumption, higher maintenance costs, and reduced vehicle lifetimes.

Additionally, real-time tracking helps identify idle zones by showing how often With a mix of driver behavior monitoring and real-time tracking, you might even be able to uncover some unauthorized use of the vehicle.

2. Map Out The Right Paths With Route Planning Software

Route planning software is crucial for any fleet-centric business owing to its potency in saving resources. This solution helps in reducing idling in collaboration with real-time tracking. It essentially helps fleet managers find and set routes in a manner that avoids as many idling zones as possible.

Read Blog – 11 Popular Myths About Vehicle Maintenance

3. Take Vehicle Maintenance Seriously

Building better vehicle maintenance schedules is crucial to reduce idling on the road.

Why?

By avoiding situations such as overheating the engine, deflated tires, etc., you can save a lot of time on the road. Especially in terms of maintenance.

Moreover, you can reduce idling time as drivers won’t have to wait for mechanics while keeping the AC on.

Alongside training drives with data, you can implement gamification to encourage proactive driving habits. Gamification adds a competitive edge by rewarding drivers who minimize idle time, encouraging better habits. The software also generates reports on harmful driving behaviors.

| Here’s a small story on how gamification can make you train better-

To cut fuel waste, a fleet manager gamified its fleet operations. Let’s name him Raj. Raj launched the “Idle Less, Earn More” challenge—drivers earned points for reducing idle time, unlocking rewards like bonuses and recognition. At first, drivers like Raju were skeptical. But as leaderboards lit up with top performers, the challenge became a game. Raju started tracking his idle time, aiming to beat his peers. Within weeks, he improved his driving habits & reduced idle time significantly. The gamified approach not only saved fuel but also boosted driver engagement. Further proving that a little competition can drive big efficiency gains. |

📌How TrackoBit’s Vehicle Tracking System Can Be Your Partner in Reducing Fleet Idling?

Partner with us to unlock powerful solutions that go beyond basic tracking. Our comprehensive fleet management software suite is designed to help you:

✅ Slash Fuel Costs, Boost Fleet Efficiency & Reduce Idle Time :

- Fuel Monitoring System: Gauge patterns of fuel levels to cut down costs & fuel wastage.

- Driver Behavior Monitoring: Gauge driver’s inconsistent or risky driving patterns that are harming the engine. Stop it beforehand and coach unruly drivers.

Ready to drive smarter and save more?

Get in touch with us today!

FAQs

-

How does excessive idle time affect fleet operation?

Excessive idle time increases fuel costs, causes engine wear, and contributes to higher emissions.

-

Can route optimization help reduce idle time?

Yes, optimized routes minimize unnecessary stops and reduce idle time.

-

Should fleet managers set idle time limits?

Yes, setting idle thresholds ensures drivers minimize unnecessary engine running.

-

What are some effective ways to reduce fleet idle time?

Implement driver training, use telematics for monitoring, and enforce idle time policies.

-

How does telematics help control idle time?

Telematics provides real-time alerts and reports on excessive idling for corrective action.

Anvesha is a communication specialist at TrackoBit. With a strong background in media and communications, she adds much-needed balance and brevity to TrackoBit’s... Read More

Related Blogs

-

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.