-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What is OBD2?

- Author:Tithi Agarwal

- Read Time:15 min

- Published:

- Last Update: May 8, 2025

Table of Contents

Toggle

Learn everything you need to know about OBD2, including what it is, how it works, and why it’s a crucial tool for modern vehicle diagnostics.

Table of Contents

Toggle

Want to keep your fleet running smoothly, improve engine health, and cut down on emissions? It’s easier than you think! The secret lies in decoding OBD2 port codes and protocols. As a fleet owner, understanding the OBDII port and its significance is crucial.

Imagine the OBD port as the superhero of vehicle diagnostics. This is where GPS trackers plug in, giving fleet managers live engine and trip insights through telematics. In this article, we dive deep into the world of OBD2, unraveling its workings, pinouts, and much more. Get ready to equip yourself with the knowledge you need to maintain an efficient and high-performing fleet.

What is OBD2?

OBD2, or OBD-II, is a diagnostics system in today’s cars and trucks.

It’s like the vehicle’s health check mechanism, consistently monitoring different parts and systems. When its system detects a potential problem, a light will pop up on your dashboard as an alert.

The OBDII system gathers crucial information from various sensors throughout the vehicle. The vehicle’s engine control unit (ECU), acting as the vehicle’s brain, processes this information to pinpoint issues. These could range from problems with the engine to exhaust emissions or even fuel efficiency.

For example, suppose you notice your fleet’s fuel consumption becoming less efficient. In that case, the OBDII might identify a faulty oxygen sensor as the culprit, signaling you to address the issue before it worsens.

This is the vehicle’s way of telling you, that there is a problem within its system, by showing you the malfunction indicator light on your dashboard.

Thanks to the OBD, fleets can:

- Track wear trends and see what vehicle parts are wearing out faster than others

- Instantly diagnose vehicle problems before they occur, supporting proactive rather than reactive management

- Measure driving behaviour, speed, idling time, and so much more

What is an OBDII Connector?

The OBDII connector is not just a plug but an important component that gives you access to your vehicle’s real-time diagnostic information and even allows you to reprogram its subsystems.

The OBD2 connector gives you vital information such as vehicle health status, performance, and fuel efficiency.

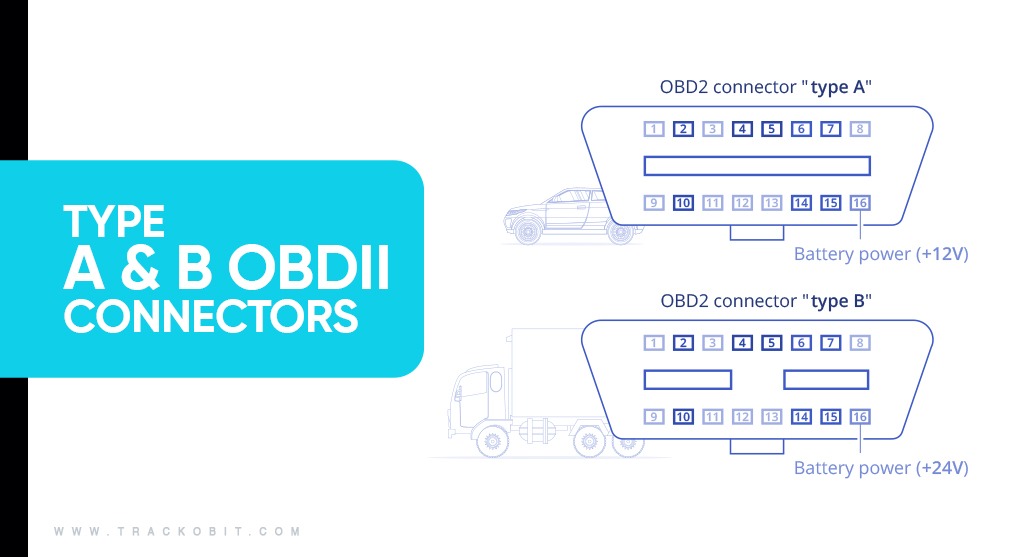

There are two types of OBD2 connectors:

- Type A for cars (12v)

- Type B for medium to heavy vehicles (24V)

The main difference lies in their baud rates—the speed at which they transmit data. Type A connectors have a baud rate of approximately 500,00 bauds(bits per sec), while Type B connectors have a maximum baud rate of 250,000.

These baud rates facilitate efficient transmission of vehicular data, such as vehicle speed, fuel levels, etc. to the diagnostics tools and devices.

Where is the powerful OBD2 connector located?

The OBDII port is generally located within two feet of the steering wheel or under the dashboard. This is the standard location, giving drivers and mechanics easy access when diagnosing vehicle issues or performing routine maintenance.

Read Blog – 6 Types of Vehicle GPS Trackers

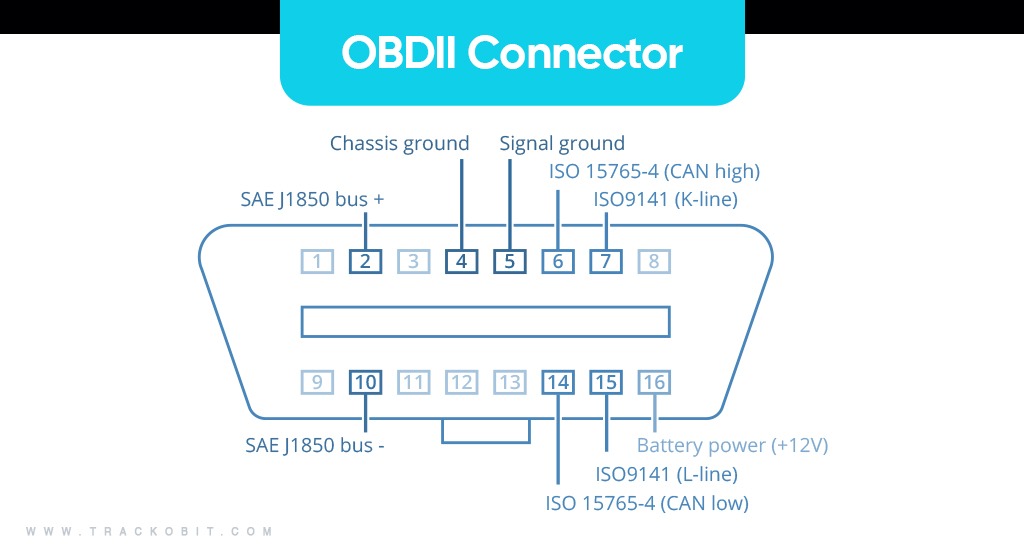

Decoding OBDII Pinouts

OBDII pinouts are key to understanding the data flowing through the vehicle’s OBD connector. There are two types: standard pins for basic communication and manufacturer-specific pins for vehicle-specific information.

Decoding these pinouts allows you to access the right diagnostic information stored in the vehicle’s onboard computer system.

Standardized Pins

Standardized pins in the OBD2 connector follow specific protocols for communication with the vehicle’s main computer system. These pins ensure compatibility with diagnostic tools and devices, allowing you to access information such as the vehicle’s make and model.

For example, pins 4 and 5 serve as ground connections, whereas pin 16 provides power from the vehicle battery (often when the ignition is off)

Manufacturer-specific Pins

Manufacturer-specific puns in the OBD2 connector convey vehicle-specific information for various vehicle manufacturers, including engine status, diagnostic trouble codes, and other engine-related details unique to each vehicle’s make and model.

The link between OBD2 and CAN bus

One important means of communication for OBD 2 systems is the CAN bus. Its requirement in vehicles or cars since 1996 in the US and 2001 in Europe proves its significance. Thanks to the Controller Area Network (CAN) bus, electronic control units (ECUs) can connect with each other. The bus also acts as a central point of access for data logging, diagnostics, and communication with network ECUs.

The California Air Resources Board has established criteria for vehicle diagnostics, and the CAN bus is one of the recommended protocols because of its effective communication mechanism. Furthermore, all vehicles sold in the US since 2008 must have OBD2 and use the CAN bus (ISO 15765) protocol.

The 5 OBD2 Protocols

Think of the OBD2 system as the lifeline of communication in your vehicle, a crucial link between your truck and diagnostic tools. But here’s the twist: not every truck or vehicle speaks the same language. Under the OBD2 umbrella, there are five distinct protocols, each with its own quirks and rules. It’s like choosing the right fuel for your ride; selecting the correct OBD2 protocol is key to ensuring smooth communication between your fleet vehicles and diagnostic gear, helping you understand your truck’s health.

Why So Many Protocols?

The variety of OBD2 protocols stems from a blend of historical favorites and evolving technological needs. They mix old-school cool with cutting-edge tech, ensuring that vehicles from different eras and regions can communicate effectively with diagnostic tools.

Knowing the pinout configuration of your vehicle’s OBD2 port can help you determine which protocol it uses. Here’s a quick guide:

-

ISO 15765 CAN

Pinout: Pins 6 and 14

This technique, which forms the basis of contemporary vehicle diagnostics, is required for all vehicles sold in the United States starting in 2008. The CAN bus system provides reliable, fast data transmission over the vehicle’s network at 250 or 500 kbps.

-

SAE J1850 PWM

Pinout: Pins 2 and 10

This protocol, mostly utilized in Ford automobiles, uses pulse width modulation to provide dependable data communication between the vehicle’s systems and diagnostic instruments. It communicates at 41.6 kbps.

-

SAE J1850 VPW

Pinout: Pin 2

General Motors favors it, has a variable pulse width and operates at 10.4/31.6 kbps. It provides a special way to communicate data that improves the effectiveness of diagnostics.

-

ISO 9141-2

Pinout: Pin 7 (K-Line), Pin 15 (L-Line, optional)

This protocol, which is compatible with a wide range of Chrysler, European, and Asian vehicles, enables asynchronous serial communication at 10.4 kbps, akin to RS-232, but with signal levels specific to automotive.

-

ISO 14230 KWP2000

Pinout: Pin 7 (K-Line), Pin 15 (L-Line, optional)

Also referred to as the Keyword Protocol 2000, it is a protocol that expands on the capabilities of ISO 9141-2. It can support a wide range of vehicle diagnostic activities and offers rates of up to 10.4 kbps. It is particularly useful for Chrysler, European, and Asian models.

How Does On-board Diagnostics Work?

Indicators, a connecting point, a network of sensors, and a central system comprise a basic OBD system, which combines all the components to provide a comprehensive monitoring system with standardized readability and access. The following parts make up the OBD system:

- ECU: The heart of the OBD system is the electronic control unit, or ECU. It gathers information from a variety of sensors located throughout the vehicle and uses it to either monitor for problems or operate certain components, such as the fuel injectors.

- Sensors: Sensors cover every part of a vehicle, from the engine and chassis to the electronic system itself. Each sensor sends codes to the ECU specifying the source and parameters of the signal. The ECU then “reads” and decodes this signal.

- DTC: The ECU stores information as a code known as a Diagnostic Trouble Code, or DTC, whenever a sensor provides data that deviates from the expected range. The DTC code is merely a string of characters representing the issue’s type and origin. DTC codes can vary by manufacturer but are often standardized. Your indicator light receives a signal from the ECU informing you that a problem has been detected when a DTC is saved. Another way to pull the DTC is to connect a sensor to the OBD system connector.

- MIL: When the vehicle’s dashboard receives a DTC code, the ECU signals the dashboard to activate the relevant indicator lights. Formally referred to as Malfunction Indicator Lights or MILs, these lights serve as an early warning system for vehicle faults. If the light comes on and remains on, there is usually a small issue. Should the light flicker, there is a major issue.

- DLC: The Diagnostic Link Connector, often known as the DLC, provides access to all the data and DTC codes collected by the ECU. The DLC port, the entry point for vehicles with OBD systems, is often positioned under the dashboard on the driver’s side, though it can also be found in commercial vehicles. The OBDII system used in modern vehicles is standard, meaning that any scan equipment with a type 2 cable can connect to the type 2 connector.

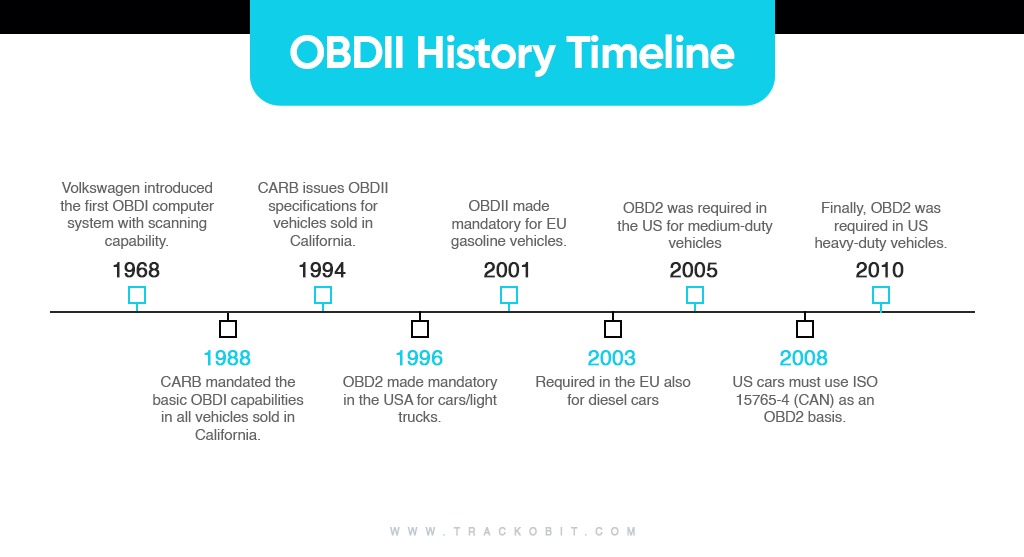

History of OBD2 or On-board Diagnostics

The California Air Resources Board (CARB) mandated OBD in all new vehicles made after 1991 to regulate emissions, which is where OBD2 first appeared.

The Society of Automotive Engineers (SAE) recommended the OBD2 standard, which standardized DTCs and the OBD connector for use by all manufacturers (SAE J1962).

Subsequently, the OBD2 standard was gradually implemented:

1996: OBD2 made mandatory in the USA for cars/light trucks

2001: Required in EU for gasoline cars

2003: Required in the EU also for diesel cars (EOBD)

2005: OBD2 was required in the US for medium-duty vehicles

2008: US cars must use ISO 15765-4 (CAN) as an OBD2 basis

2010: Finally, OBD2 was required in US heavy-duty vehicles

2013: India and Thailand made it mandatory for vehicles to have OBDII.

Difference Between OBDII and OBD

On-board diagnostics (OBD) systems, developed in the 1960s, have evolved significantly. OBD1, introduced in the early 1990s, offers basic, manufacturer-specific diagnostics for emissions control, and OBD2, mandated since 1996, provides a standardized, comprehensive system that monitors a wide range of vehicle functions.

OBD2 enhances compatibility across manufacturers, tracks various sensor data, stores fault codes for intermittent issues, and facilitates precise real-time troubleshooting. The advantages of OBD systems include enhanced fuel efficiency, early malfunction detection, cost savings through proactive maintenance, emission control compliance, and improved vehicle safety. This technology advances, integrating more sophisticated features for better vehicle diagnostics.

What are the Applications of OBD

There are several applications for OBD2 data from cars and light trucks. These include:

OBD is widely utilized as a simple means of diagnosing issues with a variety of vehicle types. But especially in the last few years, OBD’s use for vehicle monitoring and maintenance has grown to include more specialized fields. Among the most specialized uses for OBD are:

- Driver behavior monitoring: OBD systems are being utilized more often by automotive-related sectors to track driver behavior. Certain auto insurance firms, for instance, provide lower rates to customers who demonstrate their safe driving habits with vehicle data recorders. Similar data loggers can also be installed by businesses in their fleets or delivery vehicles to monitor their drivers’ actions in real time, thereby lowering their responsibility in the event of an accident or traffic infraction.

- Emissions testing: In those parts of the United States that mandate it, OBD-II testing is now a standard procedure for testing vehicles for emissions. These systems closely monitor emissions as part of the OBD-II standard, so inspectors may easily verify that the vehicle complies using a scan tool to look for emissions-related fault codes.

- Supplementary instrumentation: OBD systems are frequently used by professional drivers and automobile enthusiasts to track parameters that aren’t typically shown in stock cars. These measurements might be transmitted to the driver’s phone or shown on specially installed panels within the vehicles.

- Commercial vehicle telematics: Commercial vehicle companies commonly use Generic OBD2 to gather information about their fleet. This includes fleet tracking, fuel efficiency monitoring, driver behavior monitoring, remote diagnostics, and more.

How is OBD Used in Commercial Vehicles

Possibly, the most extensive use of OBD has been in the commercial vehicle industry, as careful vehicle maintenance is a key aspect of this industry. Commercial vehicle companies have broadly implemented the use of advanced scan tools for OBD2 systems, particularly for the following benefits that OBD-2 provides:

- Fast diagnosis: With standardized connectors and DTCs, as well as a detailed DTC system through SAE J1939, commercial vehicle problems can be identified in minutes. Technicians can pull valuable diagnostic information to identify and solve problems before they become expensive repairs by connecting diagnostic software or a scan tool to the connector port.

- Accurate information: The OBD system collects information using sensors rather than human technicians. This increases the accuracy of the information pulled, reducing the chances that a critical system error may be missed.

- Variety of metrics: OBD systems can collect various metrics beyond vehicle maintenance. They can track driver behavior to ensure drivers follow legal requirements and company protocols. Systems can also broadcast metrics over a secure line, allowing central control to monitor drivers and their vehicles from a remote location easily.

- Improved compliance: As of 2010, the standards, the EPA and the Clean Air Act set also apply to heavy-duty engines used in trucks over 14,000 pounds. Vehicles operating in certain states must be inspected regularly to ensure they comply with these standards. OBD systems monitor emissions to ensure that vehicles always meet minimum requirements. They also alert users when emissions exceed acceptable limits so that the issue can be addressed and fixed before an inspection.

- Reduced costs: OBD systems have helped commercial vehicle companies reduce costs through faster, more accurate diagnoses, expanded monitoring capabilities, and improved vehicle compliance.

Benefits of OBD-II

1. Enhance Fleet and Driver’s Safety

It is critical to monitor driver behavior, vehicle safety, and performance in order to reduce the possibility of future company liabilities such as aggressive braking, speeding, or sudden acceleration. An OBD-II unit integrated into the fleet management software tracks and generates reports on driver performance. Additionally, it creates a safety profile for every driver that serves as a benchmark for them personally.

Moreover, fleets equipped with active vehicle monitoring and driver safety policies will likely get discounted insurance.

2. Early Diagnosis of Malfunctioning Becomes Handy

It is almost impossible for drivers to identify minor issues before manifesting symptoms. A small delay in resolving the concerns occasionally leads to a complex situation requiring significant vehicle expenditure.

Here, OBD-2-equipped vehicles shine because they alert drivers to problems that require quick attention and resolution. Early problem detection in the early stages helps make proactive decisions, such as repairing components under warranty, and prevents subsequent faults, such as misfiring, before catalyst damage.

3. High Compatibility Across Vehicles

While OBD-2 systems vary based on the type of vehicle, code scanners do not since they have millions of codes stored in them. Drivers can analyze any vehicle they are given to pick up and drop off passengers in by purchasing a single scanner. This saves you from having to purchase new scanners to assess the condition of each new fleet you purchase.

Because the scanners are portable and can be transported anywhere, drivers can feel more at ease knowing that even with a small fleet, they are aware of any problems. The warning light on the dashboard isn’t going to let you know whether the sensor has failed, the vehicle might be misfiring, or you just need to oil the engine. It’s good to carry code readers for the ride.

4. Reduce Pollution

When does your cloud-based dispatch system become more environmentally friendly? It’s unquestionably incredible. The OBD-2 system helps you recognize that emission control needs to be repaired and that the fleet is aging.

Moreover, there is less of a need to check emissions routinely. As a result, fuel expenditures are reduced somewhat as a result of greenhouse gas emissions, and—above all—the environment becomes less contaminated. It is a fact that 50 pounds of carbon dioxide cannot enter the atmosphere for every gallon of fuel saved.

Read Blog – How to Choose the Right GPS Trackers in 2025?

OBD + Telematics = Atomic Explosion

OBDII and telematics together create a powerful system for vehicle diagnostics and connectivity. OBD2 provides real-time data on vehicle performance, emissions, and fault codes, which can be accessed via the vehicle’s OBD2 port. When integrated with telematics, this data is transmitted to remote servers, allowing for real-time tracking, analysis, and reporting.

Telematics enhances OBD2 by enabling remote diagnostics, predictive maintenance, and fleet management features. This combination improves vehicle efficiency, reduces downtime, and enhances driver safety. For instance, fleet managers can monitor the health of all vehicles, receive alerts for potential issues, and schedule maintenance proactively.

Overall, integrating OBDII and telematics offers a comprehensive solution for vehicle management. It leverages real-time data and connectivity to optimize performance and maintenance while ensuring compliance with emission standards.

Some of the OBD GPS Trackers TrackoBit’s Fleet Tracking Software is Compatible with are:

- Ruptela FM-Plug4+ OBD2

- Ruptela Plug5

- Teltonika FMB010

- Concox OB22

- ATrack AX11

- ATrack AX9

- ATrack AX7P

- ATrack AX7

- ATrack AX5

- Teltonika FMB003

- Teltonika FM3001

- Teltonika FMB001

Conclusion

Understanding and using OBD2 technology is vital to sustaining vehicle health. OBDII integration provides comprehensive diagnostics, monitoring a wide range of vehicle functions and offering early detection of potential issues. By leveraging OBD2, you can enhance fuel efficiency, ensure compliance with emission standards, and maintain overall vehicle safety. With tools like OBD2 scanners and vehicle telematics devices, diagnosing and addressing vehicle performance issues becomes more efficient and effective, ultimately leading to significant cost savings and extended vehicle lifespan.

Most importantly, choosing fleet management software that can interpret most of the OBD protocols is essential. TrackoBit is compatible with a wide range of OBD trackers and devices and can process most of the protocols. This helps fleet managers carry on their fleet operations worry-free.

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.