-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Tire Pressure Monitoring System – Working, Benefits and Cost

- Author:Anvesha Pandey

- Read Time:7 min

- Published:

- Last Update: December 17, 2024

Table of Contents

Toggle

Say goodbye to tire woes! Tire pressure monitoring systems tackle everything from poor traction to fuel wastage by maintaining optimal pressure. Read this piece to understand how this tool turns out to be an important tool for businesses.

Table of Contents

ToggleManaging a fleet isn’t just about moving vehicles. It’s also about maximizing efficiency, safety & cost-effectiveness. In short, it’s more about making the most of your fleet. But did you know something as simple as inconsistent tire pressure can drain your resources?

Underinflated tires increase rolling resistance. This leads to higher fuel consumption and frequent refueling. Overinflated tires reduce traction and compromise shock absorption. They also cause uneven wear and tear.

Both issues increase the risk of breakdowns and accidents. They lead to unplanned downtime, hurting your fleet’s productivity and profits.

That is where the role of the tyre pressure monitoring system comes into play. Curious how it combats the challenges mentioned above? Let’s explore!

What is a Tyre Pressure Monitoring System? Definition

A tire pressure monitoring system (TPMS) is an electronic system that monitors the air pressure inside tires.It alerts the driver or manager when the pressure drops or rises beyond the optimum level.

It’s the combination of a hardware sensor and a software unit. At least a set of three to four sensors is installed in a vehicle that captures the tire pressure at all times and sends the data to the software.

The software acts as the data processor that generates alerts and notifications every time the system records a rise or drop in pressure beyond the safe levels.

The key components of a tyre pressure monitoring system are

- Sensors

- Control Unit

- Dashboard

How Do Tire Pressure Monitoring Systems Work? (Everything in Between)

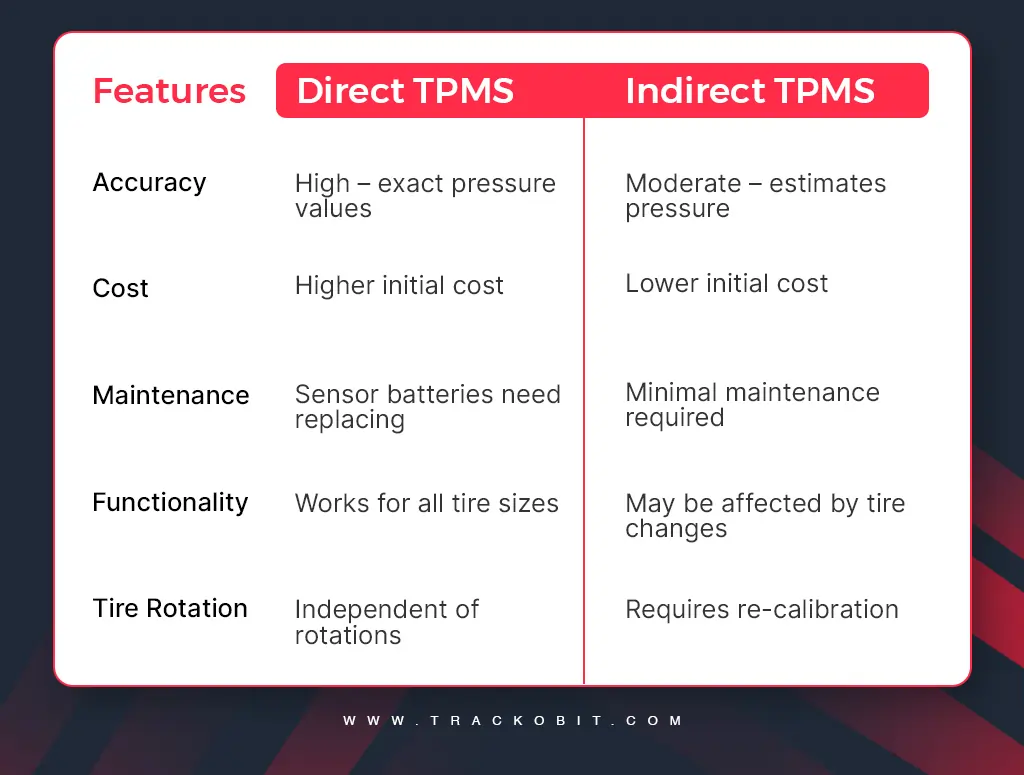

Difference between Direct TPMS & Indirect TPMS

Before we get into the major workings of the system, let’s just understand the types of TPMS.

Generally, there are two types of TPMS i.e.

- Direct Tire Pressure Monitoring System

- Indirect Tire Pressure Monitoring System

Direct Sensors are specially designed to measure air pressure & measure air and temperature inside each tire directly. These are mounted either inside the tire or on the valve stem.

On the other hand, indirect sensors rely on data from the anti-lock brake system.

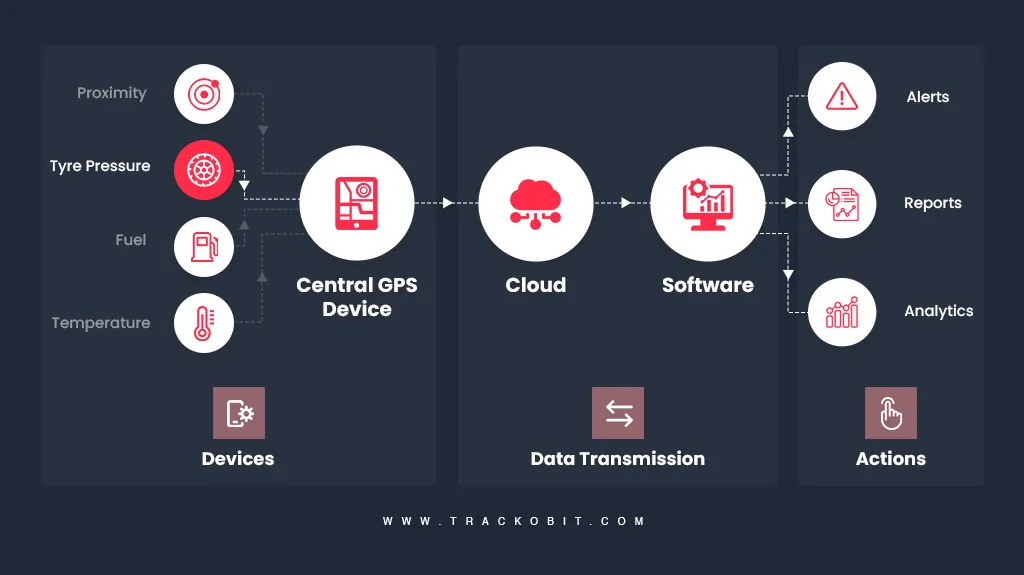

However, as far as the end-to-end working of a TPMS is concerned, here’s a step-by-step guide:

Step 1- Sensors Monitor Air Pressure & Temperature

As explained above, direct sensors are mounted inside the tires to track two important parameters i.e.

- The PSI level of the air inside the tyre.

- The temperature inside the tyre.

Moreover, these sensors constantly collect data while the vehicle is in motion or stationary.

Step 2- Sensors Send Data to the Central Unit

Once the process of data collection is done, the process of data transmission starts.

For direct sensors – This happens wirelessly using radio signals to the control unit or GPS trackers installed inside the vehicle.

For indirect sensors- Data transmission uses the ABS (Anti-lock braking system) to transmit rotational data.

Step 3- Data is Transferred to the Cloud

The control unit or GPS device acts as a hub as it helps in data processing. The cloud functions as the integration hub, where data related to tyres is combined with other vehicular metrics like fuel consumption or engine performance.

Step 4- Data Analyzation

Once the data reaches the cloud, it is sent to a fleet management software. The software further analyzes the processed data against pre-set parameters like

- Optimal Pressure Range- Fleet managers or OEMs set a pressure range (e.g., 30-35 PSI).

- Temperature Threshold- A temperature limit above which the system flags potential tire issues.

Step 5- Generation of Alerts & Notifications

If the software detects any discrepancies beyond the preset thresholds (e.g., pressure deviation greater than 20-25%), the system triggers immediate alerts.

Complete Working of TPMS

Why is a TPMS an Important Part of Tire Management?

A TPMS (tire pressure monitoring system) is an essential part of tire management because it ensures optimal tire performance, enhances vehicle safety, and minimizes operational costs.

The TPMS constantly checks tire pressure & temperature, so you don’t have to worry about low tire pressure or high tire pressure. Both situations can lead to blowouts causing accidents.

Additionally, it helps the tires to last longer by making sure they’re always optimally inflated. That’s just not all, it also provides real-time alerts for better decision-making. This further reduces downtime & keeps the vehicles road-ready.

TPMS integrates seamlessly with telematics solutions. It provides actionable insights that help optimize tire maintenance schedules and improve overall vehicle performance.

Now that you know the importance of the system, let’s quickly let’s just dive into the benefits of the system.

| 💡 Why is TPMS becoming a standard feature in modern vehicles?

This is because this system not only enhances safety but also improves fuel efficiency. In fact, in regions like the U.S. & the European Union, it has become mandatory for all new vehicles to be equipped with tire pressure monitoring systems. Additionally, integration with advanced telematics & ADAS makes it essential for modern automotive technology. |

What are the Benefits of Tyre Pressure Monitoring System?

A tyre pressure monitoring system offers several benefits to a fleet of all types & sizes.

Here’s a little showdown of the benefits of tyre pressure monitoring system-

-

Helps in Enhancing Safety

Be it underinflated or overinflated tires, both are a safety hazard. A TPMS plays an important role in preventing tire blowouts & crashes. Further reducing risk of accidents by ensuring your tires are always at the correct pressure.

This proactive feature minimizes risks & helps you prevent unwanted escalations throughout the trip. Additionally, you also get alerts when the tires are under or above the optimum pressure.

-

Prevents Unwanted Downtime

Unexpected flat tires can completely derail schedules and lead to costly delays. TPMS alerts you about potential issues early, giving you enough time to address them before they cause unplanned breakdowns. This further saves time & money.

-

Extends Tires Lifespan

Tyres that are consistently maintained at the right pressure last longer. The system ensures proper inflation, preventing uneven wear and tear, which means you’ll replace tires less often, saving much money in the long run. An ideal system provides you with real-time pressure warnings.

-

Boosts Fuel Efficiency

Incorrect tire pressure increases rolling resistance. This leads to higher fuel consumption. With an ideal tyre pressure monitoring system, the tires of your vehicle are at the right pressure. Thus, our fleet enjoys improved fuel efficiency, reducing fuel wastage. Overall, this results in lowering operational costs.

-

Reduces Maintenance Costs

By reducing the strain on the vehicle’s tires, engine, and other components, Tire pressure monitoring system helps lower overall maintenance expenses. It’s an investment that goes a long way in cutting repair and replacement costs.

-

Helps meet Compliances

With regulations in many regions mandating tire pressure monitoring system for vehicles, having this system ensures compliance and saves you from hefty fines or legal issues.

For example- THREAD ACT (2000) of the US, ECE-R64 of EU etc.

-

Provides Detailed Reports

Advanced TPMS solutions generate detailed pressure and performance reports. These insights help fleet managers make informed decisions about tire maintenance, replacements, and overall vehicle health.

All together, TPMS is an investment that not only ensures safety but also boosts efficiency & saves costs.

Why Should You Invest in TPMS?

Are you still wondering if TPMS is right for you? To clarify, we’ve outlined its benefits through two key use cases.

Use Case 1

For Fleet Managers

As fleet managers, you are responsible for ensuring the vehicles operate smoothly, safely, and cost-effectively. Proper tire pressure management is essential to avoid accidents, maintain vehicle health, and ensure efficient operations.

How is TPMS going to help you?

- The system will help you with real-time pressure warnings. This will help you take immediate actions if required & also reduce downtime.

- It is also going to extend the lifespan of tires and reduce the frequency of maintenance. Further eliminating unwanted expenses.

Use Case 2

Businesses with Heavy Vehicle Utilization

Companies with fleets that are frequently on the road face higher risks of tire wear and unexpected breakdowns. Such types of fleet management challenges can result in disrupted operations, increased expenses & also impact profitability.

How is TPMS going to help you?

- Helps you ensure consistent tire monitoring to avoid operational disruptions caused by tire-related issues.

- Improved fuel efficiency directly impacts the bottom line for logistics companies operating large fleets over long distances.

Altogether, TPMS stands out to be a practical, cost-effective solution for ensuring safety, improving efficiency, and maximizing the ROI of your fleet operations.

How Much Does a Tire Pressure Monitoring System Cost?

The cost of a tyre pressure monitoring system may vary depending on various factors such as the type of sensor, the number of devices installed, and the brand you decide upon. On the software front, the more sophisticated the tool is, the higher the prices go.

Having said that, a complete tire pressure monitoring system costs between $50-$200.

However, OEMs usually give you an in-built TPMS. When you choose TrackoBit’s fleet management software, you get TPMS functionality built with other special features. There you don’t have to worry about paying for different systems additionally.

Which is the Best Tire Pressure Monitoring System (TPMS)?

As far as the best tire pressure monitoring system is concerned, TrackoBit has established its name as the best in the fleet and logistics space.

This fleet management software is popular for its top-notch accuracy along with advanced fleet monitoring solutions – Video Telematics, Route planning and optimization, Fuel Monitoring, and Driving Behaviour Analysis to name a few.

Can you count on TrackoBit’s new-age telematics software for end-to-end optimization of fleet operations? Absolutely yes.

Intrigued?

Talk to our experts to know more!

FAQs

-

How to reset a tyre pressure monitoring system?

To reset TPMS, inflate all tires to the recommended pressure, then press and hold the TPMS reset button (usually under the steering wheel) until the dashboard light blinks. Drive the vehicle for about 10 minutes to recalibrate the system.

-

How often should TPMS sensors be maintained or replaced?

TPMS sensors typically last 5-10 years but may need maintenance or replacement if they fail to transmit accurate readings. Regular tire servicing can help identify sensor issues early.

-

Can TPMS improve fuel efficiency?

Yes, properly inflated tires reduce rolling resistance, improving fuel efficiency. Under-inflated tires can increase fuel consumption by up to 3%.

Anvesha is a communication specialist at TrackoBit. With a strong background in media and communications, she adds much-needed balance and brevity to TrackoBit’s... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.