-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What is Maintenance Repairs and Operations (MRO)? It’s Importance and Types

- Author:Tithi Agarwal

- Read Time:8 min

- Published:

- Last Update: December 4, 2025

Table of Contents

Toggle

An effective maintenance repair and operations (MRO) service boosts profitability by streamlining processes, cutting costs, and enhancing efficiency.

Table of Contents

Toggle

Maintenance, repair, and operations (MRO) supplies and activities are essential to running a business. Businesses or vendors providing facilities management software and services understand the importance of streamlining MRO services.

The users be able to reduce their equipment procurement budget. Also reduce facility, equipment, and employee downtime. Learn how to ace your HVAC task planning game with an optimized MRO supply chain and MRO inventory.

What is MRO (Maintenance Repairs and Operations)?

MRO is an acronym for maintenance, repair, and operations.

It involves activities associated with maintaining the company’s assets. This includes physical supervision activity performed on buildings (including any structures and grounds). It further involves thorough inspection of electrical, lighting, HVAC, and plumbing systems. It also includes equipment used to produce finished goods or deliver services.

Let’s further define what maintenance, repair, and operations means.

- Maintenance refers to actions taken proactively to prevent an asset from breaking down. Proactive strategies include preventive, condition-based and predictive maintenance.

- Repair refers to actions taken to restore a non- or underperforming asset to operational condition. This type of reactive activity is called corrective maintenance (CM).

- Operations involve managing the day-to-day activities that help the business run efficiently. These operations include:

b) Asset and equipment management

c) Spare parts inventory management

d) Preventive maintenance planning and scheduling

e) Work request management

Why is Maintenance Repair and Operations Important?

MRO is important because it impacts an organization in four main areas.

1. Maintenance Costs

Asset failure is inevitable, but poor maintenance increases the frequency and cost of repairs, leading to production shutdowns, damaged products, and missed opportunities. It also reduces asset lifespan, forcing costly replacement or repair decisions. Outsourcing repairs adds to expenses.

Optimise In-house field service maintenance scheduling with the right software to reduce the organization’s budget.

2. Inventory Control

Executing MRO repair requires the organization to purchase a variety of materials, supplies, HVAC tools, and parts. However, it is common in small businesses for staff to make MRO purchases without strong procurement skills. Because of this, inventory management is often out of control.

For example, it is common for operation staff to over-order in fear of running out of stocked items. However, uncontrolled purchases lead to wasted money and cluttered stockrooms. Which runs the risk of stocking obsolete parts.

3. Plant Productivity

Poor MRO repair management results in a number of hidden costs due to low employee and operations productivity. It’s best to track employee productivity to reduce the cost of upkeep services.

Organizations that operate on a reactive strategy wait around for assets to fail. And when they do, it leads to excessive downtime that could have been reduced or avoided.

Teams for repair and maintenance tend to perform unproductive work without proper documentation of maintenance needs.

4. Purchasing and Procurement

Organizations constantly purchase goods and services to support MRO efforts. Maintenance staff commonly makes a large number of unplanned, low-cost purchases. Such costs, when combined, often exceed the organization’s total expenditure.

Proper maintenance repair operations management is necessary to reduce purchasing costs. It does so through volume discounts, vendor management, and other inventory optimization techniques.

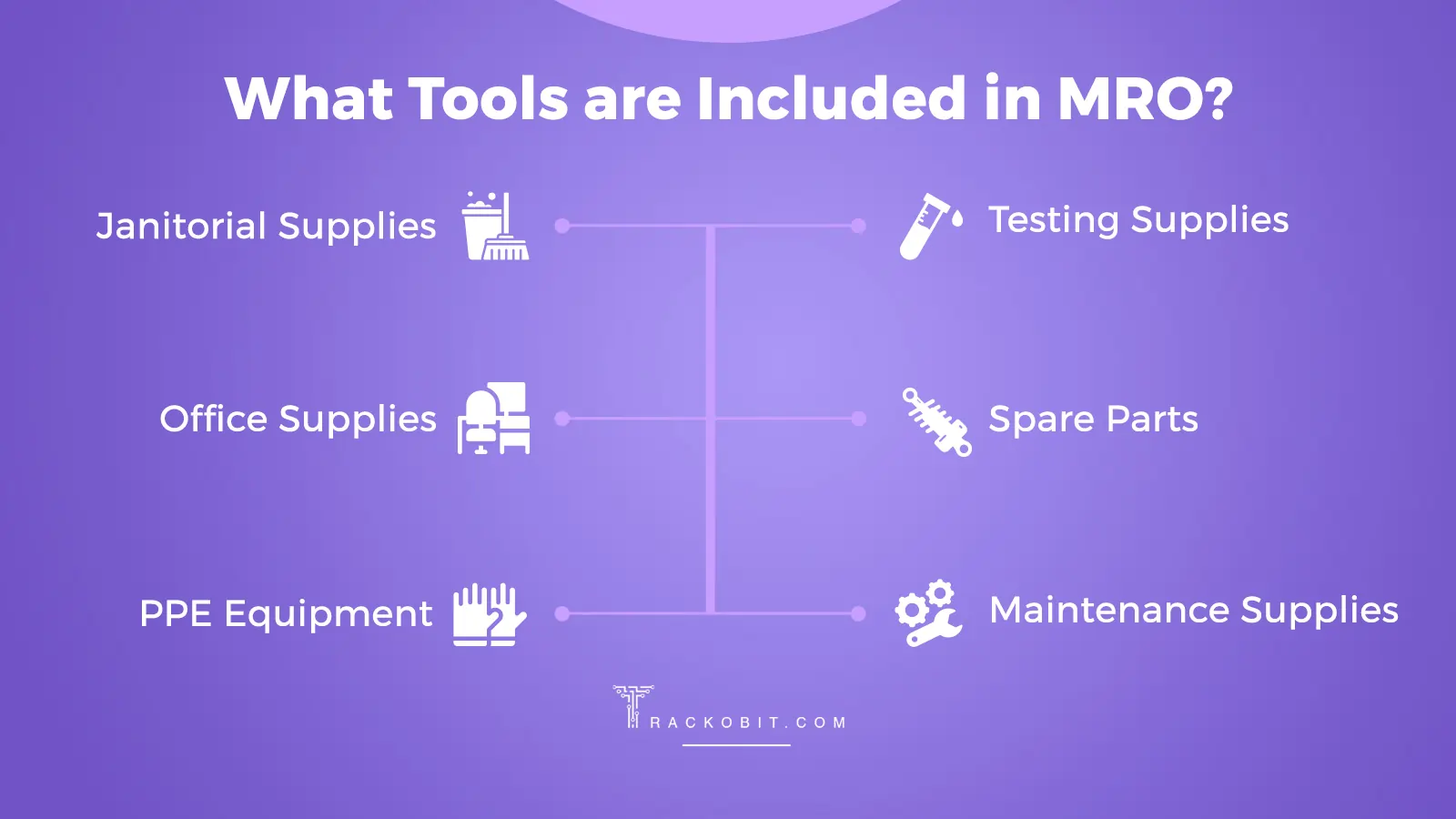

What tools are Included in MRO

What Tools are Included in MRO?

Specific maintenance repair operations service supplies differ from business to business. Examples of MRO supplies typically include — but aren’t limited to:

- Janitorial supplies: Related to keeping a facility’s interior clean and clutter-free. Examples include industrial cleaners, sanitizing solutions, mops, and brooms.

- Office supplies: Computers, paper, marker boards, paper clips, and pens are all prime examples of MRO supplies for office work.

- Personal protective equipment (PPE): This includes safety gear such as gloves, respirators, face shields, and earplugs.

- Testing supplies: Test tubes, scales, centrifuges, and beakers are some prime examples of laboratory testing supplies.

- Spare parts: Easy-to-store pieces like bearings, spare motors, and gears are a few extras that production facilities often keep on hand.

- Maintenance supplies: Lubricants, nuts, bolts, and valve seals are a few components that many operations find helpful.

What are the Types of Maintenance Repair and Operations?

These services can be divided into several subcategories, including:

1. Infrastructure Repair and Maintenance

This type of operation focuses entirely on the integrity of the facility and its surrounding premises. It deals with the upkeep and repairs of roofs, walls, doors, and windows. But activities like landscaping, snow removal, and pest control also fall under this category.

These responsibilities are typically assigned to internal employees. However, depending on their background and qualifications, not all workforces can handle everything. Infrastructure repairs are important because they are essential for smooth facility maintenance operations.

2. Production Equipment Repair and Maintenance

This type deals with all the assets and equipment directly involved in manufacturing. Its purpose primarily is to prevent unnecessary unscheduled downtime and minimize material waste.

Companies typically use a combination of preventive and predictive measures, along with on-demand work orders, to prevent material wastage and downtime.

3. Material Handling Equipment Maintenance

This type of maintenance repair operation ensures smooth resource import and product export.

Companies tend to outsource this type of work to 3PLs. However, that doesn’t mean it’s not vital. If your plant doesn’t receive the shipment of materials it needs for production, you won’t make anything. Similarly, if something goes wrong while you’re shipping the final products to the customers, you won’t get paid.

4. Tools and Consumables

These include work tools (e.g., wrenches, hammers, drills, nails, etc.) and work safety equipment (e.g., gloves, masks, protective eyewear, helmets, earplugs, etc.). Together, these items are also known as “MRO inventory.”

They are vital because they allow employees to work to their fullest potential. In turn, keeping a good stock of inventory can lead to improved work efficiency, higher productivity, and more.

The Role of MRO in Supply Chain Management

With well-planned MRO supply chain management, your team can plan the operation in advance and minimize downtime.

1. Inventory Management

MRO inventory management keeps needed supplies in stock by tracking current store levels and replenishing depleted supplies.

2. Procurement

Maintenance repair operations procurement involves acquiring materials. These are for facility management, equipment repair, and operations.

3. Vendor Relationships

Many organizations use vendor-managed inventory. To handle MRO tracking, storage, and resupply, reducing internal management burdens.

4. Supply Chain Optimization

Optimization of the MRO Supply chain maximizes efficiency by monitoring and adjusting steps in the supply chain. MRO service vendors identify pain points in the production line and logistics and transport challenges, address immediate issues, and implement more efficient processes.

Benefits of MRO

What are the Benefits of Maintenance Repair and Operations?

There are many benefits of performing MRO services activities, including:

1. Minimizing unplanned downtime

Just one piece of equipment not working can throw the entire production line into chaos. This disruption can negatively impact the company’s bottom line. And also increase field employee idling. Organizations that incorporate these operations can better plan routine maintenance. So they can keep their factories online. Furthermore, using field employee tracking software can help you say goodbye to employee idling.

2. Avoiding stockouts and overstocking

An automated approach to MRO services means organizations are better equipped to know when all their MRO equipment, tools, and products need replenishment. Vendors also know if they have too much of a product, which leads to an overfilled stockroom.

3. Maintaining compliance

Many regions and industries have regulations on health, safety, and equipment upkeep. Keeping heavy industrial equipment cleaned, serviced, and stocked with parts ensures compliance.

💡Pro tip: HVAC software drives business growth. As it is an essential tool for scheduling jobs to avoid legal violations.

What is MRO Inventory Management?

MRO inventory, or spare parts inventory, varies by business. Management of these items is a major component of these strategies. This is because both inventory shortages and unnecessary overstocking can create problems.

Most organizations do not understand their MRO equipment purchases or requirements. As a result, they underestimate the cost of MRO inventory. Which hurts overall profitability.

MRO inventory management strategies also vary. Some organizations might engage in a regimented procurement process. To streamline purchasing and ensure the best pricing for high-quality maintenance repair operations materials.

Others might turn to inventory management software. That will track purchase orders and make real-time decisions about inventory.

What are the 3 Main MRO Maintenance Strategies?

Preventive, predictive, and corrective maintenance strategies are the most common approaches:

1. Preventive Maintenance

This is the act of performing regular activities to help prevent unexpected failures. It covers a range of proactive activities and general tasks. For example, each production component within a system requires regular servicing. Some even require the repair or replacement of certain parts. An example is a factory’s HVAC system.

2. Predictive Maintenance

This uses real-time and historical data to predict the future health of equipment. And also anticipate problems in advance. It relies on various technologies. Including the Internet of Things (IoT), predictive analytics and artificial intelligence (AI).

3. Corrective Maintenance

This strategy is also called reactive maintenance. Corrective maintenance tasks are only performed once an asset has broken down. This approach assumes that asset downtime costs are usually lower than the expenses of a full program.

Streamline maintenance repair and operations Service Staff Scheduling with TrackoField

TrackoField is field employee tracking software. It is vital to track and monitor service technicians who are performing services. The software provides GPS location intelligence, explaining the staff’s current geolocation. The live location helps schedule tasks according to availability and proximity to the task site.

You also get complete visibility on task progress and ultimate status. The software lets you geofence task sites. To keep track of employees’ arrival or departure from them. It even tells the task location and timeline. Which enhances your business’s reporting capabilities.

What more do you get?

Service tasks assigned vs. accomplished status. Which provides 2x the visibility of the technicians’ productivity.

TrackoField offers many more solutions that will help streamline your MRO services. Check them out by clicking on the banner below.

Frequently Asked Questions

-

Is Repair and Maintenance an Operating Expense?

Yes, repair and maintenance are typically considered operating expenses as they are necessary for day-to-day operations.

-

What Is the Work of MRO?

MRO work involves maintaining, repairing, and operating equipment or facilities to ensure smooth, efficient production and operations.

-

What is MRO inventory?

MRO inventory consists of spare parts, tools, and supplies needed for maintenance, repairs, and operations in industrial facilities.

-

What Is MRO Material?

MRO materials are supplies, tools, and equipment used for maintaining, repairing, and operating production facilities and machinery.

-

What is maintenance repair and overhaul?

Maintenance, Repair, and Overhaul (MRO) refers to the comprehensive process of inspecting, repairing, and restoring equipment or machinery to ensure optimal performance, safety, and longevity, typically in industrial settings.

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

How to Track Field Employees Offline With Field Force Management Software

Mudit Chhikara February 11, 2026Use field force management software to track field employees offline and ensure managers never lose visibility of on-ground operations.

-

How AI-Powered Field Force Management Simplifies Field Operations With Analytical Dashboard

Mudit Chhikara February 10, 2026How AI-powered field force management enhances field operations using AI manager bot and analytical dashboard.

-

Grameen Credit Score and the Quiet Redesign of Rural Lending

Pulkit Jain February 9, 2026Rural lending doesn’t usually go wrong at approval. It drifts when what’s happening on the ground stops being visible.

-

How NBFCs Can Reduce NPAs Using LMS + LOS + FFA Integration

Mudit Chhikara January 30, 2026Here’s how NBFCs can smartly integrate LOS, LMS, and FFA software to reduce NPAs and ensure seamless field operations.

Subscribe for weekly strategies to boost field team productivity.

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.