Companies aiming to grow and scale should have thriving and robust commerce. Because of this, companies are increasingly recognising the importance of outsourcing their fulfilment and logistics to a 3PL provider. Third-party providers impact the supply chain, from cost savings to improved customer service.

Also, by outsourcing to 3PL providers, companies can leverage an extensive and efficient network of carriers and partners with the latest technology, infrastructure, and knowledge. While many 3PLs focus solely on product packing, warehousing, and/or distribution, some are large enough to handle additional tasks. Streamlined delivery and logistics is key to maximum efficiency.

Here is a guide that will cover everything you need to know about 3PL before outsourcing to one.

What is 3PL (Third Party Logistics)?

3PL stands for third-party logistics, a singular term encompassing eCommerce logistics management and operations. Third-party logistics (3PL) refers to outsourcing your order fulfilment process and management to another company. Different types of 3PL service providers serve distinct functions based on your business’s needs.

A 3PL provider handles your warehousing, picking and packing, transportation, and last-mile delivery so you can focus on priority tasks. Utilising a 3PL service both frees up your time and decreases the likelihood of in-house fulfilment errors. It’s a form of leverage that allows you to allocate more energy to big-picture concerns, like product development or branding.

Types of 3PLS

Most 3PLs offer various services, but not all are the same and function the same. Some 3PLs might specialise in one or two areas.

-

Transportation

3PLs focusing on transportation handfuls mostly handle inventory shipping between manufacturers, warehouses, and even between companies and buyers. Generally, these are freight that transport a large shipment/cargo from one country to another or to small parcel shippers.

-

Warehousing, Fulfillment, and Distribution

This is the most common type of 3PL that provides basic fulfilment services like storage, picking and packing, shipping, and handling returns. Sellers going for this 3PL intend to outsource all or most of their fulfilment and warehousing needs. If they offer to manage the seller’s transportation, identify which shipper to use, manage the relationship between seller and shipper, and optimise the shipping strategy, then it is your dream 3PL. You should go for it.

-

Financial Services

These third-party logistics (3PLs), mostly employed by larger e-commerce businesses, optimise your business's logistics network by offering services like accounting, cost control, freight forwarding, inventory tracking and management, and other related tasks.

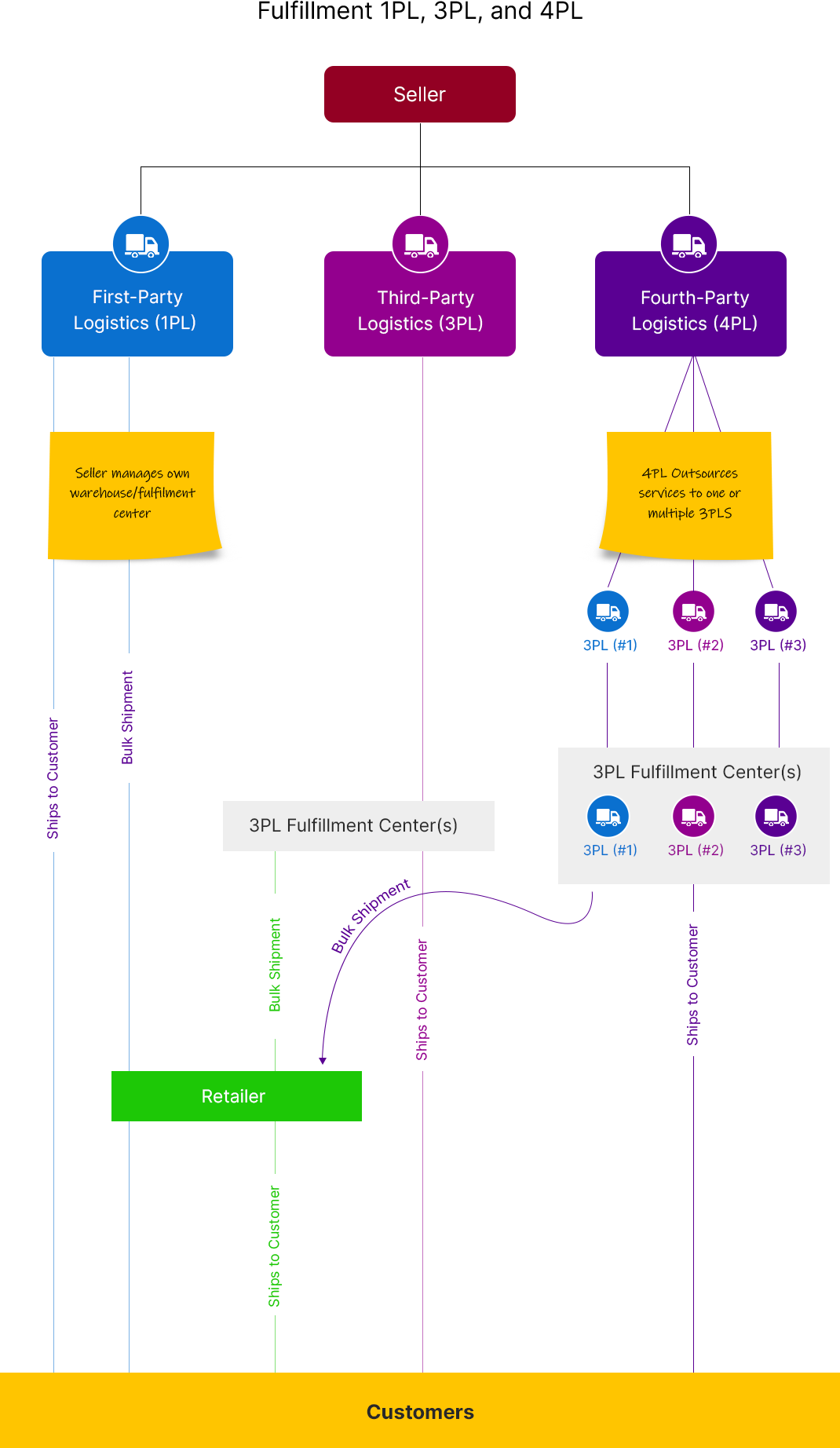

What is the Difference Between a 1PL, 3PL, and 4PL?

3PL Order Fulfillment Process

What happens in a 3PL fulfilment centre could appear mysterious if you've never outsourced shipping or are considering working with a 3PL provider.

However, there's no reason why the 3PL fulfilment process has to be mysterious.

What precisely occurs at a 3PL's e-commerce warehouse when a customer orders from the company’s website? Let's explore the process from beginning to end.

-

Receiving

A 3PL cannot ship orders without inventory on hand. In a 3PL warehouse, accepting and storing new inventory is called "receiving" inventory. Every 3PL can receive and store inventory using its own procedures.

-

3PL Warehousing

3PL stores your inventory in its fulfilment centres after receiving it. Every SKU (stock-keeping unit) has a specific storage place, which can be on a pallet, bin, or shelf.

Storage capacities vary among 3PLs; not all 3PL warehouse space is made equal.

-

Picking

Picking is the next step after a customer places an order. The submitted order will then be processed by an order management system and forwarded to the relevant 3PL warehouse or fulfilment centre. Upon receipt, the order is "picked" out of the warehouse or storage bin to be shipped to the customer. Verify the 3PL's technology to ensure bar code scanning is used to guarantee pick accuracy.

-

Packing

Once every item in an order has been selected, it's time to package them safely for delivery. The products being shipped, your preferred brand, and the 3PL's capabilities will all influence the packing materials used.

-

Shipping

Order shipping is the next step. The majority of 3PLs will buy and print shipping labels for you. While some 3PLs compare shipping quotes from multiple carriers, others have preferred carrier partners. The latter enables 3PLs to give customers the most economical pricing for their selected delivery speed.

-

Returns

A lot of 3PLs also provide services for handling returns. If a customer ships an order back to your 3PL, they will handle the return and, based on their policies and your preferences, either restock the item or dispose of it. You can go for a 3PL that give your clients return shipping labels.

8 Must Have 3PL Services

Depending on your selected supplier, 3PL fulfilment services can differ from order shipping to other aspects. These are a few of the best attributes and typical logistics services provided by 3PLs.

-

Inventory Management

With the help of a 3PL, you should be able to monitor the real-time inventory levels at each third-party fulfilment centre. This allows you to effortlessly sync inventory with your online store, and proactively reorder inventory to avoid stockouts.

-

2-day Shipping

Consumers anticipate prompt, reasonably priced shipping with just a few clicks. Because 3PL warehouses store inventory closer to your shipping destination, their location can make all the difference in your ability to meet and exceed customer expectations. By partnering with the appropriate 3PL, you can offer your customers 2-day shipping at a reasonable cost.

-

Distributed Inventory

When working with a 3PL that has multiple warehouse locations, you can divide inventory among fulfilment centres so that each order is shipped from the 3PL warehouse closest to your customer. We refer to this model as distributed inventory.

-

B2B and D2C Fulfilment

Using a multichannel logistics strategy can simplify your life by helping you find a 3PL that can handle both B2C and B2B fulfilment.

-

Advanced-Data Analytics

To assist you with everything from year-end reporting to improved supply chain decision-making, 3PLs provide free analytics tools that are jam-packed with charts and deep insights. With such insights you can see how many days it takes for your orders to be delivered, historical stock levels at any point in time in any location, average storage cost per unit, and much more.

-

International Fulfilment

Scale your brand across the globe with a 3PL that has a physical presence in several countries (and even cross-border solutions). In today’s convenience economy, 3PLs like ShipBob are committed to helping brands grow their brands globally in markets like the US, Canada, Australia, the United Kingdom, the EU, and more.

-

Return Management

In order to further expedite the customer experience, 3PLs can handle returned orders and even integrate with returns software solutions to assist your returns management process.

-

Knitting and Customisation

Crafting an amazing unboxing experience can help your brand stand out from the crowd and make an impression. 3PLs can facilitate this by creating custom gift notes, packaging, kitting, and sender labels.

What are the Benefits of Working with a 3PL?

There are many benefits to outsourcing order fulfilment to a 3PL.

-

Saving Time and Money

By forming a partnership with a 3PL, you can avoid full-time employing or renting the labour, technology, warehouse space, and logistics operations needed for in-house fulfilment. As your business expands, fulfilling orders yourself becomes increasingly expensive. These expenses include workers' compensation, liability insurance, recruiting and labour costs, warehouse space, forklift costs, and other equipment.

-

Leverage Industry Expertise

For businesses listed on e-commerce websites, they don't have the time to learn every aspect of logistics and shipping. This is where a 3PL can help: staffed with experts in e-commerce logistics, they are informed about the most recent developments in the market, saving you from being stagnant.

Additionally, 3PL businesses have the technological know-how and network of partners (marketing firms, providers of bespoke packaging, and so forth) that enable them to continuously enhance the effectiveness of their supply chains and carry out supply chain optimisations to support the growth of e-commerce.

-

Expand Your Reach

Your company's potential is limited if you only sell in one area. You can reach a wider audience by collaborating with a 3PL.

Whereas internal fulfilment is limited, 3PL companies have a vast network of fulfilment centres. Working with a 3PL with fulfilment centres nationwide can reduce order transit times and shipping costs.

-

Expedited Shipping

By using a 3PL to handle order fulfilment and shipping on their behalf, sellers can take advantage of their scale and provide advantages like additional technology, shipping choices, and discounts, which they can't provide if they handle order fulfilment internally. In addition to helping sellers increase sales, a 3PL can assist in meeting customer demands regarding expedited shipping and costs.

An established 3PL will already have a sophisticated technology infrastructure, a network of warehouses, and skilled personnel to ensure prompt and effective delivery. They can easily resolve any shipping problems and follow a package from beginning to end. Furthermore, their reputation relies on their ability to deliver packages in good condition, on schedule, and to the correct location.

-

Seamless Reverse Logistics

Returns management, or reverse logistics, is crucial to any e-commerce fulfilment process. It covers every step required to return goods from the end user to their original location, either the direct manufacturer or a third-party logistics provider (3PL) that manages the order fulfilment process. Returned goods must be disposed of or reintegrated in cases of damage, inaccuracy, or a consumer’s change of mind.

-

Technological Benefit

Third-party logistics providers use a wide range of technological solutions. They can be integrated with different platforms and other systems like delivery management software. This can help streamline processes like order dispatching and delivery. It can also help customers track their orders.

How TrackoMile Backs the 3PL Process?

For 3PL fulfilment to succeed, it is important to consider the last part as well—delivery of the order. By integrating software dedicated to making last-mile delivery smooth and successful, 3PL providers and businesses both stand to benefit.

Here is a list of TrackoMile’s last-mile delivery solutions that ensure orders are dispatched and fulfilled at ultra-fast speed.

-

API

TrackoMile's easy integration through API into any preexisting platform or software makes it easy for managers to manage data, shipments, and labour from a centralised platform. Businesses can achieve greater automation, reduce manual errors, and enhance operational efficiency within their delivery processes.

-

Dispatcher Tool

Pair orders, riders, and resources in seconds with the dispatcher tool feature. The solution considers the availability of resources and the nature of the shipment, such as delivery time window, time sensitivity, and emergency. If there is a shortage of capacity or resources, the system reschedules instantly without human input.

-

Carrier Management

The software’s carrier management feature makes assigning orders to the right vehicles easy based on size, capacity, and load restraints. It even lets you set parameters such as a maximum number of items per vehicle, weight, and volume depending on the size of the vehicles. This helps optimise carrier utilisation.

-

Route Optimisation

Last-mile delivery software optimises routes for delivery by considering 120+ factors, ensuring that drivers take the most efficient paths to reach their destinations. This optimisation can reduce fuel costs, minimise travel time, and increase the number of deliveries completed within a given timeframe.

-

Rider App

The rider app provides all the important details regarding delivery riders' jobs, tasks assigned, schedules, orders, best-suited routes, customer details, and important instructions. The app entails a chatbox where riders can effortlessly communicate queries or confusion with managers. The app also has a feature to mark riders' attendance and collect POD.

-

Rider Roster

The rider roaster feature provides a comprehensive view of the available drivers and vehicles and their shift schedules. This makes scheduling riders even easier, as dispatchers do not have to call to know the driver’s bandwidth, proximity, or availability.

-

POD

Many last mile delivery software solutions offer electronic proof of delivery (ePOD) capabilities, allowing drivers to capture signatures, photos, or other verification methods upon completion. This feature helps prevent disputes over delivery status and provides a record of successful deliveries for both the 3PL provider and their customers.

-

Real time Tracking

With real-time tracking features, 3PL providers can monitor the location of their delivery vehicles and shipments. This visibility allows them to provide accurate ETAs to customers, improve delivery accuracy, and quickly respond to any delays or issues during transit.

-

Analytical Reports

Last mile delivery software collects performance data, including delivery times, driver productivity, and customer satisfaction ratings. Analyzing this data allows 3PL providers to identify areas for improvement, optimize their delivery operations, and make data-driven decisions to enhance customer service and reduce costs.

Fulfil and deliver orders at 3x speed.

Easy integration with TrackoMile and 3PL ensures streamlining of order fulfilment, economical and on-time delivery.

Partnering with a 3PL Can Change your Business for the Better

Partnering with a 3PL provider is proving to be a wise decision for companies that are either struggling to fulfil orders on their own or are looking for ways to save time, money and free up resources. Doing so allows them to focus on improving product development, marketing and business growth.

However, go for a trustworthy fulfilment service provider that can handle growing inventory and provide a positive customer experience. This will eventually lead to the business growing and scaling.

Most importantly, when choosing a 3PL provider, ensure the integration of last-mile delivery software as it increases the efficiency of order fulfilment and delivery speed 2X.

Schedule a demo now!Frequently Asked Question

-

Why do companies use 3PL?

Companies use third-party logistics (3PL) for their expertise in streamlining supply chain operations, reducing costs, and improving efficiency. 3PL providers offer specialized services such as warehousing, transportation, and inventory management, allowing companies to focus on core business activities while benefiting from optimized logistics solutions.

-

What is 3PL logistics?

Third-party logistics (3PL) involves outsourcing logistics functions to external providers. These providers offer services such as transportation, warehousing, distribution, and fulfillment. By leveraging 3PL expertise, companies streamline supply chain operations, reduce costs, and improve efficiency, allowing them to focus on core business activities and enhance customer satisfaction.

-

How to choose a 3PL provider?

When selecting a 3PL provider, consider factors like industry experience, technology capabilities, scalability, geographic coverage, and service offerings. Assess their track record, client references, and transparency in communication and pricing. Prioritize a provider aligned with your specific business needs, goals, and growth plans for optimal results.

-

What is a 3PL warehouse?

A 3PL warehouse is a physical location where a fulfilment company stores products, processes orders, and ships them. The best 3PL warehouses are positioned strategically, ideally in locations that can reach many addresses in two days or less, with standard shipping.

You Are Just One Step Away