-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Coolant Temperature – How it Works, Best Practices to Maintain It

- Author:Tithi Agarwal

- Read Time:6 min

- Published:

- Last Update: June 5, 2024

Table of Contents

Toggle

Regulating the coolant temperature and preventing heating up through timely maintenance will keep your fleet operation cool and running. Best practices unfolded here.

Table of Contents

Toggle

Fleet managers maintain tight timetables with limited leeway to satisfy their clients’ demanding needs and maintain the business’s productivity. Their fleet’s constant repair and care is a daily problem in keeping the firm operating. The last thing a fleet needs is unplanned downtime, which may be expensive. Choosing the appropriate lubricants and fluids and performing proper fleet maintenance are crucial to this upkeep.

One of the major factors affecting an engine’s longevity and performance is coolant temperature. In this blog, we will discuss coolant temperature, how it works, and how important it is to maintain it. In addition, we will cover software and coolant temperature sensors, which are essential components for monitoring and managing engine temperature.

What is Coolant Temperature?

The term “coolant temperature” describes the temperature of the coolant that runs through the engine’s cooling system to keep it running at a certain temperature. Coolant, which is a water and antifreeze mixture, dissipates heat from the engine’s hot metal components. Depending on the kind of engine and the environment it runs in, coolant temperatures can vary.

How Does Coolant Temperature Work?

An internal combustion engine, the kind most commonly found in vehicles, depends on liquid coolant to operate properly. Coolant is a liquid that travels throughout the engine to absorb heat from the exhaust manifold, cylinder head, and engine block, among other parts. The coolant absorbs heat and then dissipates it by the radiator, which releases it into the surrounding air.

The engine block or cylinder head contains a sensor tracking the coolant temperature. The engine control module (ECM), also known as the powertrain control module (PCM), is the computer that manages the engine’s functioning. This sensor detects the coolant’s temperature as it passes through the engine.

What Happens When Coolant Temperature Goes Up?

Although modern engines are designed to be durable, dependable, and efficient, the coolant system in your fleet vehicles may start to malfunction if the motor produces significantly higher heat than usual. This may harm the vehicle’s engine and other parts, eventually stopping the vehicle and making it unusable. There are multiple causes for a vehicle to overheat and perform below par.

- Leakage in the cooling system makes the pressure drop and reduces the boiling point of the coolant

- Radiator cap or thermostat that has gone bad or is stuck

- The water pump or drive belt has stopped functioning

- A low amount of coolant reduces the air from getting into the system

- Mechanical issues like a faulty head gasket

- Malfunctioning cooling fan and accessories

- Debris stuck in front of the radiator that is restricting the airflow

What Does the Coolant Temperature Sensor Mean?

A temperature sensor primarily tracks the engine’s performance and gives the engine control unit (ECU) feedback, which controls the engine’s temperature. The sensor measures a thermistor’s resistance, which varies with temperature. The thermistor’s resistance lowers as the engine temperature rises due to continuous driving, and the sensor transmits a signal to the ECU, which modifies the fuel mixture and other settings to maintain the desired engine temperature.

Using this data, the ECM or PCM can modify the engine’s operating parameters, including the fuel delivery quantity and ignition timing. For instance, the engine can run too high if the temperature deviates too much from the optimal range. This indicates that it will consume gasoline excessively and emit too many emissions. And a temperature that is too high can cause the engine to run too lean. This indicates that it will consume gasoline excessively, which could lead to overheating or component damage.

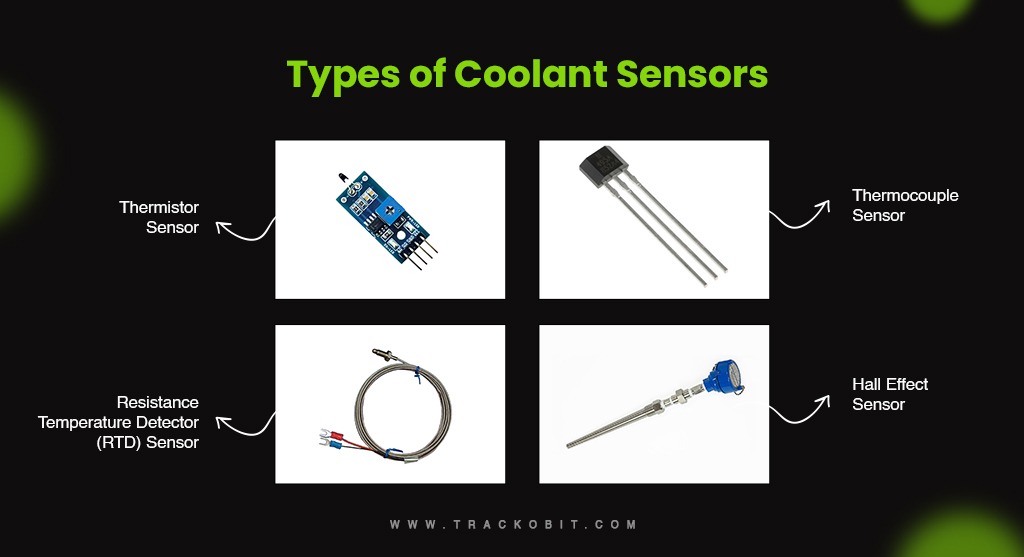

Types of Coolant Sensors Used in Modern Vehicles

- Thermistor Sensor: This kind of sensor uses a thermistor, a kind of resistor that alters resistance in response to temperature variations. The thermistor’s resistance varies with coolant temperature, and this variation is used to determine the temperature.

- Thermocouple Sensor: This type of sensor employs two wires made of different metals joined together at one end. When temperature changes occur, the sensor generates a voltage between the two wires, which is used to calculate the temperature.

- Resistance Temperature Detector (RTD) Sensor: This type of sensor uses a wire made of a material that can change its resistance as the temperature changes.

- Hall Effect Sensor: This type of sensor uses a magnetic field to measure temperature. The magnetic field also changes as the temperature changes and the temperature is calculated.

The type of coolant sensor used in a vehicle depends on the make and model of the vehicle and the specific requirements of that engine’s cooling system.

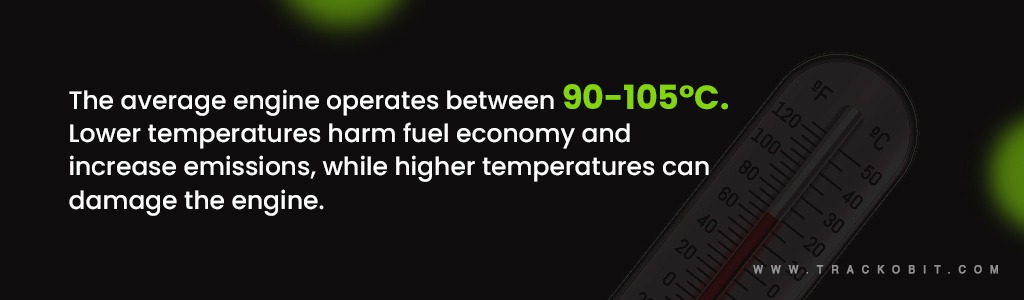

Importance of Maintaining Coolant Temperature

Ensuring the engine runs effectively and safely requires maintaining the proper coolant temperature. If the engine runs too hot or too cold, its lifespan might be shortened, and damage can occur. Operating the engine too cold can result in more pollutants and less fuel economy while operating it too hot might cause the engine to seize. The ideal temperature range must be maintained to guarantee that the engine runs at its best and lasts as long as possible.

Temperature monitoring is crucial to an internal combustion engine’s healthy operation. It precisely monitors and controls the cooling system and engine control system components.

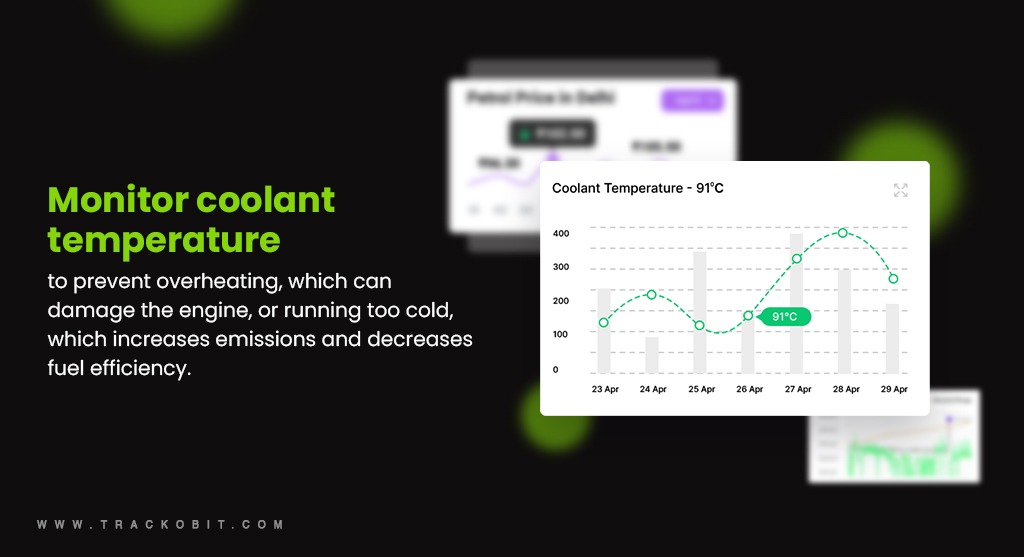

Coolant Temperature Maintaining Software

Coolant temperature maintenance software is an essential component of modern engine control systems. TrackoBit is compatible with all types of coolant temperature sensors. It receives input from various sensors, including the temperature sensor. This ensures the engine operates within its desired temperature range.

Fleet maintenance with coolant alerts

Fleet management and maintenance are significant components of logistics and transportation operations. A coolant alarm is essential for this management since it helps protect your vehicles. Even though the coolant temperature has increased, there are situations in which the vehicle’s engine may not shut down. When this occurs, fleet maintenance software enables you to receive coolant notifications continuously until the problem is fixed.

TrackoBit’s solutions for high coolant temperature issues

An engine that overheats quickly is likely to suffer damage quickly. Proper maintenance and measurement are essential for the longevity of your vehicle and its engine, as well as to guarantee the simple and trouble-free operation of your cooling system.

The need is for a system that assists with careful monitoring and can prevent unwanted vehicle damage. Through TrackoBit’s dashboard, you can monitor your coolant system and ensure the temperature is kept at the ideal levels to minimise difficulties and vehicle downtime.

TrackoBit is compatible with every external coolant temperature sensor and the OBD plug that is useful in measuring engine parameters directly. The Electronic Control Unit (ECU) can provide vehicle data when the OBD tool is connected to the port. In addition to warning you when the temperature exceeds 105 degrees Celsius, TrackoBit allows you to set custom thresholds as needed. Keep track of the aforementioned reasons for variations in coolant temperature and take immediate action to address the issue by staying informed about the condition of your vehicles.

Conclusion

An engine’s ability to operate properly depends critically on the temperature of the coolant. The proper temperature range must be maintained to guarantee the engine runs effectively and safely. The coolant temperature sensor and maintenance software are crucial for tracking and controlling engine temperature. Regular cooling system maintenance and checking coolant levels are crucial to maintain the ideal engine temperature.

TrackoBit, through its preventive maintenance solution, real-time tracking and monitoring of vehicle health and temperature, and instant alerts, will help prevent the vehicle from heating up.

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.