-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What is Fleet Maintenance? Benefits & Examples of Fleet Maintenance

- Author:Tithi Agarwal

- Read Time:10 min

- Published:

- Last Update: June 11, 2024

Table of Contents

Toggle

Preventive and corrective fleet maintenance affects the fleet’s operational as well as repair costs. To know more about such benefits and examples of fleet maintenance, read this article.

Table of Contents

Toggle

One of the biggest investments in your fleet is your vehicle. Taking good care of them is essential to running a successful company. If you don’t take a proactive approach to fleet maintenance, you risk endangering the safety of your workers and failing FMCSA inspections. Besides, you will have to pay for expensive emergency repairs and experience unscheduled downtime. Furthermore, the condition of your vehicles can serve as a reliable general indicator of the state of your company.

However, tracking the maintenance schedule of such a large number of vehicles or which truck needs corrective or preventive maintenance can be hard. This is until you have fleet management software that effectively takes care of this for you.

This article discusses types and benefits to help you understand fleet maintenance. Have a read, and if you have any questions, feel free to connect with TrackoBit for a free demo to learn how to enhance your fleet operations.

What is Fleet Maintenance?

Fleet maintenance is the practice of keeping company vehicles in good operating condition for safety, reliability, and longevity. It involves performing recommended periodic maintenance, replacing parts, and tracking asset history to avoid unexpected breakdowns.

Types of Fleet Maintenance

There are two types of maintenance that happen within fleets: corrective and preventive maintenance.

- Corrective maintenance is often unscheduled and done as a reaction to a failed item on a vehicle.

- Preventive maintenance (PM) is a proactive approach to fleet maintenance – where regular maintenance is scheduled and performed to prevent failure of vehicle components.

What are the Benefits of Fleet Maintenance?

Several benefits that are motivating more businesses to give fleet maintenance and management top priority include:

Improved Inspection and Testing Outcomes: The Federal Motor Carrier Safety Administration mandates that vehicles undergo regular testing and inspections to guarantee safety on public highways. Establishments possessing robust and reliable fleet management initiatives stand a greater possibility of obtaining favourable outcomes and safety clearance.

Reduced Operational Costs: Strong fleet maintenance programs directly result in reduced operating expenses. Vehicles in good functioning order consume less gasoline. The decrease in unscheduled downtime, which results in higher organizational output, is an even more significant factor.

Reduced Repair Costs: Periodic maintenance is cheaper than prematurely replacing expensive parts, which helps manage maintenance costs for the organisation. Fleet management enables an organisation to detect problems and take care of them before they escalate.

Lower Fuel Costs: When you upgrade your fleet’s maintenance plan, you’ll also see savings in fuel costs. Simply changing the oil and filters in your vehicles regularly will boost miles per gallon. Tire and wheel maintenance is another important factor in fuel efficiency. In fact, Automotive Fleet Magazine reports that proper maintenance can improve fuel economy by as much as 40%. That’s a huge benefit for any commercial fleet.

Driver Satisfaction: Mechanical problems are stressful and frustrating for your drivers. They don’t want to deal with roadside breakdowns, worry about whether those balding tires will have good traction in bad weather, or wonder if the brakes will work well enough to stop in time to avoid an accident.

Decreasing Downtime: Downtime is a curse for any fleet or maintenance manager. With on-time fleet maintenance, fleet managers can timely send their fleet for repair, which helps reduce downtime and could also lead to the loss of clients and projects.

Increasing equipment lifespans: Maintenance can help you extend the life of your vehicles and other equipment by providing service reminders. For example, consider a tractor—a staple piece of equipment in agriculture. The average tractor has a lifespan of about 10,000 hours. However, with proper care and preventative maintenance, a high-quality tractor can last over 20,000 hours.

Retained Resale Values: Companies can use maintenance service records as evidence that a vehicle is in good operating order when leasing out or selling one. They are able to obtain the finest deal on their vehicles as a result.

Ensured Regulatory Compliance: According to the Environmental Protection Agency (EPA), vehicles contribute the largest portion of carbon emissions at 28 percent. The agency has laid down a number of regulations for the automotive sector aimed at protecting the environment. Implementing a fleet maintenance program helps companies ensure adherence to the regulations.

Improved Customer Satisfaction: By guaranteeing that goods and services are delivered to clients on schedule, fleet management helps to provide exceptional customer service.

Businesses that neglect to prioritise fleet maintenance face the danger of unscheduled downtime, expensive emergency repairs, and potential safety issues. In short, fleet management is essential to any organisation that depends on automobiles for success in moving forward.

Want to stay ahead of your competition? Looking for advanced fleet management solutions?

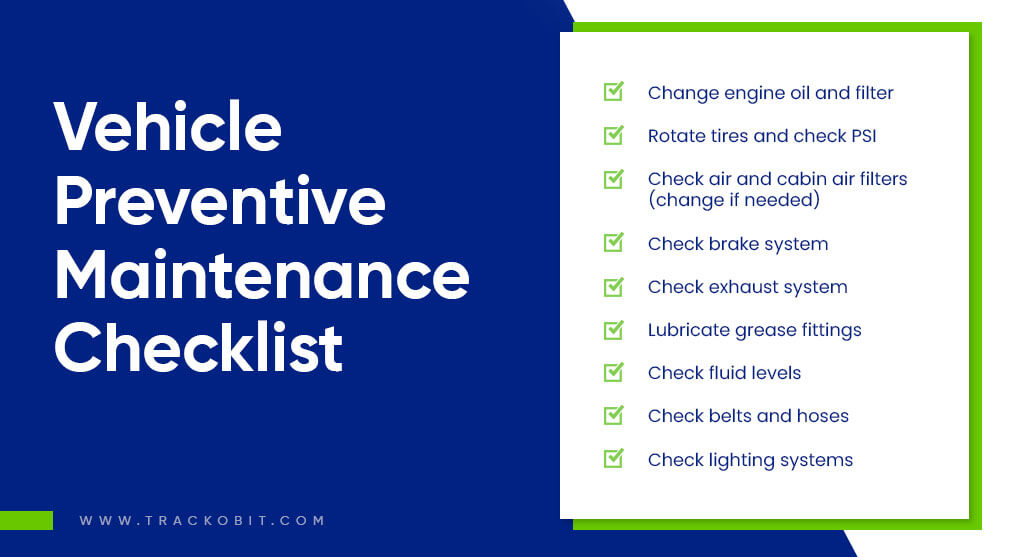

Examples of Fleet Maintenance

Short-term vehicle inspections often include evaluating:

Oil and Filters: Engine motor oil must remain at optimal levels to lubricate moving parts, seal against debris, and keep the engine cool.

Tires: Well-maintained tires are crucial to safe, fuel-efficient rides. Technicians must check tire pressure, depth, and need for rotation.

Air Filters: Not only are properly flowing air filters good for driver health, but they’re also vital for engine health. Regularly changed air filters increase fuel efficiency, decrease harmful emissions, and extend engine life spans.

Coolant Levels: Low coolant levels lead to engine problems.

Headlights, Turn Signals, and Breaks: These elements are vital to safety.

Long-term fleet inspections often include inspecting:

Transmission Fluids: Similar to engine oil, transmission fluid lubricates moving parts that keep transmissions working.

Transfer Case Fluid: Transfer cases shift power from the transmission to the axles in both four-wheel and all-wheel drive vehicles.

Shocks and Struts: Wearing shocks causes a decrease in smoothness in steering control and driver safety.

Coolant Fluid Exchange: Regularly flushing coolant systems rid engines of contaminants and ensure radiators are properly operating.

Spark Plugs: Malfunctioning spark plugs cause engines to slowly lose power over time, which can lead to costly replacements.

Serpentine Belts: Belts play an important role in powering peripheral devices, including alternators, power steering pumps, and air conditioner compressors.

Front/Rear Differentials: These devices help transfer torque, or power, from the engine to the tires. That’s why differentials must be kept lubricated.

Season, weather, and driving conditions also affect fleet vehicle requirements. For instance, hot weather increases the likelihood of battery depletion compared to winter. Tyres, coolant levels, and windscreen wipers are a few other fleet components that are significantly impacted by outside variables.

How can Fleet Maintenance and Management be Improved?

Using fleet management software like TrackoBit is the simplest approach to enhancing maintenance and fleet management systems. These solutions allow organisations to track all vehicles in a single, central database. Standard operating procedure (SOP) checklists can be assigned, drivers’ behaviour can be observed, sensors and GPS trackers can be integrated, and managers can schedule repairs.

Vehicle Health Monitoring

TrackoBit continuously monitors the health and performance of fleet vehicles using telematics data and onboard diagnostics. It can detect issues such as engine faults, low fluid levels, or abnormal behavior and alert fleet managers in real-time. This proactive monitoring helps in identifying maintenance needs before they escalate into costly repairs.

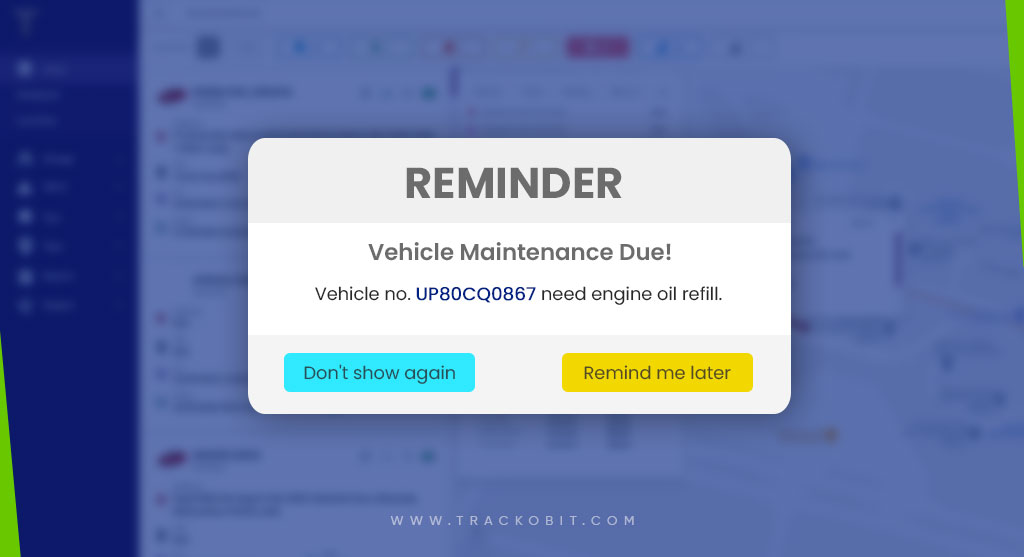

Schedule Maintenance and Service Records

Keeping track of maintenance schedules for a large fleet can be daunting. The software automates this process, reminding you when service is due and keeping a detailed history of past maintenance for each vehicle. This historical data can be invaluable for diagnosing recurring issues and planning future budgets.

Preventative Maintenance Insights

By closely monitoring your engine fault code information, you can proactively attend to engine issues before they become costly repairs. While some competitors may claim to provide DTCs (Diagnostic Trouble Codes), TrackoBit’s real-time reports provide more comprehensive and accurate data, allowing for quicker and more accurate diagnosis of vehicle issues. With Engine Status Reports, you can detect early signs of vehicle engine health issues, prevent breakdowns, and avoid more costly repairs down the road.

Also, fuel monitoring reports instantly detect excessive fuel consumption, which prominently indicates that something is wrong with the vehicle engine or any other part.

Driver Behaviour Monitoring

Harsh driving can take a toll on vehicle conditions. Improving driver behaviour is one way to help. Even the simplest vehicle repairs can be costly to your bottom line. Minimize vehicle wear and tear with TrackoBit’s driver scorecard and proactive driver coaching tools. For those instances when wear and tear is inevitable, be alerted the instant issues are detected with our fleet maintenance solutions.

Automated Alerts and Reminders

Efficient fleet management software sends automated alerts and reminders to fleet managers and fleet mechanics when scheduled maintenance tasks are due. These notifications ensure that no maintenance tasks are overlooked, helping in proactive maintenance planning and execution.

Here’s How TrackoBit Helps You Stay on Top on Maintenance Schedule

Driver App for DVIR

Exclusive to TrackoBit, its driver app allows drivers of each vehicle to inspect the truck before starting the trip and form a DVIR report. To start a DVIR (Driver Vehicle Inspection Report) driver simply opens the mobile app and selects DVIR on the dashboard. A pre-set list of common defects makes selecting and leaving details on defects easy. Critical defects are automatically highlighted for attention.

Tyre Pressure Monitoring System

Tyres of commercial vehicles can cost up to lakhs, and the best way to elongate their lifespan and reduce wear and tear is through proper maintenance and pressure monitoring. With real-time pressure and temperature monitoring and alerts and detailed tyre health monitoring reports, you can easily maintain their health and prevent breakdowns, flat tyres, or busts.

Types of Fleet Maintenance Workers

Fleet maintenance requires several different types of workers to implement successfully. The three types of workers involved in fleet maintenance are:

Drivers: No one spends more time with fleet vehicles than drivers. It is their duty to carry out daily diagnostics as a result. Vehicle warning signs should be observed and communicated by fleet drivers first.

Fleet Mechanics: Large organisations frequently invest in specialised in-house mechanics to perform routine maintenance on a fleet of vehicles. However, many businesses discover that hiring service centres and authorised garages to handle their fleet maintenance is more economical. When necessary, these professionals carry out maintenance tasks.

Fleet Managers: Fleet managers manage the general fleet and maintenance plans. They are consulted on all maintenance schedules and strategies. Fleet managers are also in charge of buying new vehicles and selling old ones. Their primary goal is to maintain vehicle value through planned maintenance, fuel-efficient route planning, wise purchase and sale choices, and adhering to safety regulations.

| TrackoBit offers a long list of customisable alerts and reminders to help fleet managers stay informed of their fleet health:

Fuel monitoring alerts Tyre pressure monitoring Driving patterns causing stress on the engine Collision Preventive Alerts

|

Conclusion

Fleet maintenance, whether proactive or corrective, will have a profound effect on the life span of your fleet vehicles. As a business owner who is dependent on the fleet to carry out operations, whether offering logistics or owning an in-house fleet, being proactive in fleet maintenance is a dire necessity. Have no second thoughts about it.

We admit it is not easy to detect or keep track of the maintenance schedule, but that is if done manually. Why not seek help from fleet management software that, with a magnifying glass, tracks vehicle health and sends instant alerts if it notices any defect?

Look no further than this blog, as TrackoBit is more than enough investment to help to proactively manage your fleet maintenance. You get vehicle health reports and solutions to tune down wear and tear.

Less Garage Time = Less Vehicle Downtime

Schedule a free demo today!

Some Popular Reads:

- Fuel Savings Are Critical For Small Business Survival

- Why You Should Always Opt For Custom Fleet Management Software

- How Temperature Monitoring Reformed the way Logistics Operates

Frequently Asked Questions

-

What is the role of maintenance in fleet planning?

Fleet maintenance is vital for monitoring and tracking the vehicle’s condition. It includes activities such as predictive maintenance, inventory management, remote diagnostics, and so on. Implementing good vehicle maintenance procedures can quickly fix an issue when one arises.

-

How do you manage fleet maintenance?

Managing vehicle maintenance programs should be the most important consideration in your daily operations checklist. You can manage it by maintaining the scheduling process, streamlining the workflow, and following up for inspection. It is an important aspect of ensuring cost-effective, reliable, and safer operation.

-

How to reduce fleet maintenance costs?

You can reduce the fleet maintenance cost by adopting practices such as managing inventory, controlling vehicle scheduling, maintaining vehicle records, embracing new-age technology, etc. Tracking these factors tends to promote fleet efficiency and reduce operational costs.

-

What is the best fleet management software?

TrackoBit has the most cost-effective fleet management software that can monitor your vehicle's operating condition. Managing the entire maintenance lifecycle of vehicles improves fleet efficiency and avoids vehicle breakdowns.

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.