-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Tips to Build a Solid Fleet Management Strategy (Beware! It Works)

- Author:Nandita Gupta

- Read Time:10 min

- Published:

- Last Update: August 30, 2024

Table of Contents

Toggle

Running a fleet without strategizing? You are doing it all wrong. Here, note down just 9 ways to form a spectacular fleet management strategy.

Table of Contents

Toggle

Strategic planning, not erratic actions, is the key to successful fleet operations!

Managing a fleet of hundreds of vehicles comes with the responsibility to maximize uptime, reduce overhead costs, and enhance road efficiency. This requires strategic planning and actionable steps to keep your delivery vehicles operating at their best.

So, let’s jump to steps to build a solid fleet management strategy, but before that, let’s understand…

What is a Fleet Management Strategy?

Fleet management plan or strategy involves proper planning, documentation, and execution of goals and processes for managing, maintaining, and optimising a fleet. This allows the bottom lines of saving costs, increasing uptime and efficiency, ensuring on-schedule arrivals, and potentially earning good margins to become a reality.

There is no “one size fits all” fleet management plan. And there is no order in which the strategy should be planned or executed. It’s built out of sheer trial and error done by fleet managers (also lots of sacrifice and sweat).

Since we don’t like logistics and supply chain businesses staying stranded, we have developed easy steps on how you can develop (your very own) effective fleet management strategy.

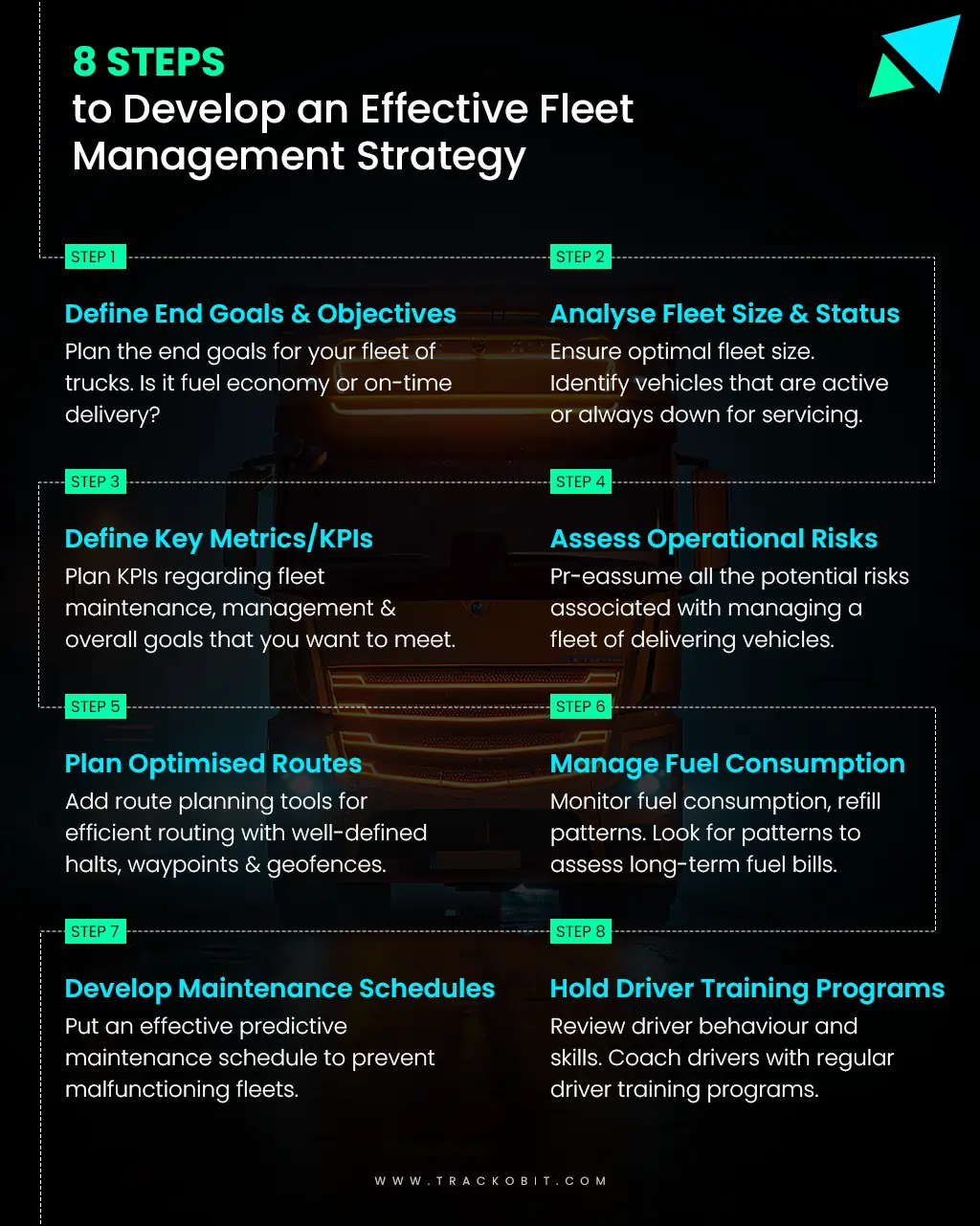

9 Easy Steps to Develop an Effective Fleet Management Strategy

Steps to Develop a Fleet Management Strategy

Here are a few steps that are used in developing a fleet management strategy:

Step 1- Define End Goals and Objectives

Establish clear goals and objectives that give a purpose to running your fleet operations. We are sure you are using your delivery fleet for a purpose. Think over your goals, to ensure safe arrival/delivery of the consignment, reduce fuel costs, improve driver safety, increase on-road performance, or surpass clients’ expectations.

After that, examine your fleet’s current state and look for areas that require improvement. Analyze current roadblocks and think of some solid techniques that can help yield positive results. Quantify how many of your vehicles are efficiently running on the road, parked idle at lots, or inactive at the moment. Thereafter, think of creative mainstream objectives and KPIs based on those findings.

| 💡Some Inside Information!

Do you know the mega-brand Coca-Cola’s main objective is to enhance operational efficiency by planning strategic routes and improving vehicle utilisation to ensure on-time deliveries between its warehouses and distribution centers. And how do they ensure that? To achieve this desired efficiency, they use advanced routing software and a telematics system. |

Step 2 – Analyze Your Current Fleet’s Size and Status

Inspect your current vehicle types, ages (are they nearing disposal), maintenance records, fuel consumption, and overall performance. This will help analyze any bottlenecks obstructing you from achieving cost-effective and efficient fleet operations.

To make it more fun, you can make an expectation vs. reality report. In this report, you can set up your benchmarks (defining how things should be) and match them against current status (how things are). Additionally, define what remedial actions can be taken to cure the gaps.

Here’s how you can do this.

Vehicle Type – Light Commercial Truck

Fleet Quantity – 30 Trucks

| Factors | Expectation | Reality | Need for Change |

| Fuel Consumption | 500 gallons/truck×30 trucks=15,000 gallons/month | 800 gallons/truckx30 trucks = 24,000 gallons/month | Requires efficient route planning, better vehicle upkeep, and active tracking of fuel consumption and idling patterns. |

| Maintenance Cycle | 2-4 cycles per month | 5-6 cycles per month | Requires serious tracking of driver behavior and duly tracking of vehicles’ status via eDVIR reports. |

| Delivery Time per 100 km trip | 1.5 to 2 hours | 3-4 hours | Requires better route management, better monitoring of halts and trips, and a constant eye on driver behaviour. |

Step 3 – Define Key Metrics or KPIs

Identify the key metrics that you will be measuring to set benchmarks and define success. Commonly, fleet management KPIs can be:

- Achieving more fuel economy (by reducing long routes, fixing driving patterns, and timely sending vehicles for maintenance).

- Reducing maintenance cycle and costs and improving vehicle uptime (by scheduling well-timed maintenance trips).

- Improving driver behavior and skills (by gauging their patterns and getting alerts for every risky driving event).

- Improving fleet compliance (by enforcing DOT and the FMCSA (Federal Motor Carrier Safety Administration) regulations to prevent accidents, breakdowns, and driver errors).

Tracking all these KPIs will help you run an efficient, on-time, and compliant fleet and reduce your business expenses. You know what, with a powerful fleet management system, vehicle telematics, and IoT devices for geospatial tracking, you can easily track and assess these KPIs. This can enable you all fleet managers to reduce overheads and TCOs (total cost of ownership).

Step 4- Assess Risks and Make Redressal Plans

Running a fleet without risks is next to impossible. You anticipate it or not but there are looming risks of fleet theft, sudden downtime, and a fatal collision that adds to insurance costs. That is why it’s wise to understand and note all the kinds of risks and make a redressal plan for them already.

Fleets violating traffic rules or accidentally bumping into other vehicles are a few of the common furies of fleet managers. To mitigate such issues, as a part of your redressal plan, the best solution would be to incorporate video telematics solutions supported by the best 360-degree cameras and sensors. So you get alerted each time the vehicle is risking on-road safety.

This approach can better help you anticipate risks throughout your entire operational journey and be ready with solid mitigation strategies.

Must Read: What is an Engine Immobiliser? How does it help prevent thefts?

Step 5 – Plan Optimised Routes & Trip Schedules

Look for optimum route planning solutions to plan the most optimised trip itinerary for your hundreds of trucks with to and fro details of custom tours, halts, waypoints, and geofences with their names.

TrackoBit lets you define the most efficient route and even limit the duration of your stay at each halt. You can also sequence the waypoints according to the urgency or priority of your delivery address.

Strategizing over better routing/route management practices can help you reduce delayed consignment deliveries. In the long term, it will also reduce fuel consumption, help you keep up with on-schedule fleet dispatch, and most of all, keep up with the trust of your clients.

Read Blog – How to do route planning from A to B – With Trip Planner tool

Step 6 – Manage Fuel Consumption

Your fleet management plan is incomplete if you are not reviewing and deciding on better fuel management and cost analysis.

During the planning stage, look for some workable ways to explain how you can control your fuel costs, and constantly monitor the consumption pattern/fluctuations. Doing this small exercise will even encourage your drivers to switch to more fuel-efficient driving skills (like not putting in abrupt brakes or acceleration).

Here’s how to determine the economical fuel consumption for a fleet of 30 trucks per month.

**Please note that analysis can vary depending upon the following factors:

| Type of Trucks | Fuel efficiency differs for light, medium, or heavy-duty commercial trucks. |

| Miles Driven | The total distance is driven by the fleet over a period of a month. |

| Load Carried | When a vehicle carries a heavier load, its fuel efficiency will be lower. |

| Average Fuel Efficiency | Average fuel efficiency is defined by miles per gallon (MPG) for each truck. |

| Driving Condition | Is it for urban areas or rural areas with improper roads? The choice affects fuel consumption, too. |

Now, here’s an example of how to estimate fuel consumption:

Let’s say:

- The average MPG (Miles Per gallon) of the trucks is 6 miles per gallon (estimated for heavy-duty trucks)

- Average Distance of each truck/month is 3,000 miles.

Then, for one truck:

The total fuel consumption/truck = 3000/6 = 500 gallons

Here’s the consumption for a fleet of 30 trucks:

30 Trucks Total Fuel Consumption = 500 gallons/truck X 30 trucks = 15,000 gallons/month

Once you are aware of how much fuel is consumed by vehicles in your fleet, next is to strategize over economical fuel consumption patterns by:

- Planning more efficient and economical routes and trips.

- Constantly monitoring fuel fill/pilferage events with the best fuel monitoring system.

- Keeping up with regular maintenance of vehicles.

- Monitoring driver behavior (to avoid harsh acceleration, cornering, and braking).

Note:

Focus on reducing average distance or improving your truck’s MPG to reduce fuel consumption.

Step 7 – Develop Maintenance and Inspection Schedules

A vehicle’s malfunction and breakdown mid-route can add to unwanted repair costs! It’s best that you devise a proactive vehicle maintenance plan that looks ahead into practices that can help extend your vehicle’s life span and reduce risky breakdowns.

Please note that the number of monthly fleet maintenance cycles can vary depending on your fleet size, type, and how frequently they are on the road. Here’s the maintenance cycle schedule that you can stick up to:

|

|

|

Apart from the above in-depth maintenance, and routine inspections, routine inspections can be done more frequently, if possible weekly or bi-weekly. |

|

Divide the most heavily used or long-haul travelled vehicles. Ensure these ones are serviced after every 2-3 weeks. |

|

Some fleets’ maintenance depends on the mileage they drive.

For instance, if a vehicle has accumulated a lot of miles, it may require maintenance every 3,000 to 5,000 miles. |

|

Maintenance cycles can vary as per the season. Extreme weather conditions such as winter may require more frequent vehicle inspections. |

In typical scenarios…

- 1-2 maintenance cycles per month are suited for light-duty commercial trucks.

- 2-4 monthly maintenance cycles per vehicle are suitable for heavy-duty commercial trucks.

Step 8 – Invest in Highest Quality GPS Trackers & IoT Sensors

It’s given how important it is to invest in top quality types of vehicle GPS trackers and hardware. But one thing that businesses miss is investing in major IoT sensors or devices that can actually relay tons of insightful information. This will eventually protect their assets from fatal mishaps.

So while you are in your strategizing phase, make a list of what all kinds of IoT sensors you would be using along with top-quality GPS trackers.

Here are all the additional sensors, we highly recommend you add:

- Typre pressure sensors – To get alerted for real-time PSI levels to prevent abrupt tire blowouts.

- Fuel sensors – To track down fuel refill/pilferage events.

- Load sensors – To identify the load hauled in the construction, farming, or waste management trucks.

- Temperature sensors – These are used to track the temperature fluctuations in the reefer trucks to ensure effective cold chain monitoring.

You may explore a wide range of IoT hardware and sensors to fit your tracking needs. No matter the device, TrackoBit seamlessly integrates with over 1,500+ types on the market.

Step 9 – Don’t Skip Investing in Driver Training Programs

Train drivers on safe and highly fuel-efficient driving techniques. You can do this by leveraging drivers’ driving footage or videos captured through our video telematics solutions. You can present this visual data weekly or maybe in bi-weekly meetings with your driving staff.

Use this to teach them the repercussions of driving recklessly on the road. Share how one harsh acceleration or abrupt cornering can risk not only a vehicle’s engine health but also compromise pedestrian safety.

Have robust driver behaviour monitoring software in place that provides data on inattentive and careless driving patterns, supported by a driver scorecard that scores drivers based on their driving skills. When you have the data and score, it’s easy to take action, right away.

Here’s are Some Other Strategies for Improving Fleet Management…

- Keep up with the habit of engaging with stakeholders – It’s best if you engage all the stakeholders (clients, transporters, or any high command authority) while planning the strategy, maybe they can help refine it.

- Plan for the Future – While making big plans, think from the perspective of the foreseeable future; try incorporating electric and autonomous vehicles in place.

- Fleet data centralization – You cannot do without comprehensive fleet management software that automates all your computations and analysis, especially when dealing with datasets from large fleet size.

- Ensure Compliance – Stay up-to-date with regulations and legal requirements that justify drivers’ optimum Hours of service.

Read Blog – Types of GPS Trackers TrackoBit Supports

Let’s Together Implement a Powerful Fleet Management Strategy!

Running fleet operations without thinking is the worst thing you can do. Not having a common motive and execution steps can make it hard for your business to know where your money is going, why your clients are frustrated, or why your fleet is always down for servicing.

Total Chaos, isn’t it?

So make things right and start working on a flawless fleet management strategy with the tips you just explored.

While getting into the process, don’t forget to onboard a scalable and intuitive fleet management software that tracks every event of your operations.

TrackoBit would love to be your ally. Together, let’s build and work on building a base wherein you can track your fleet operations, reduce your costs, and add your overheads back to your budget.

Shall we start with a free demo?

Nandita is the Team Lead for Content Marketing at TrackoBit, bringing over a decade of experience in B2B, B2C, and IoT sectors. She has a proven track record of helping Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.