-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What is the Difference Between Repair and Maintenance?

- Author:Mudit Chhikara

- Read Time:6 min

- Published:

- Last Update: October 13, 2025

Table of Contents

Toggle

Repair and maintenance are two commonly confused terms and are often used interchangeably. Let’s learn about the difference between the two.

Table of Contents

Toggle

Sooner or later, everything perishes! Equipment, infrastructure, technology, or any other assets have a life expectancy, and their failure is inevitable.

However, you can extend the service life of most assets with maintenance and repair. In fact, most organisations have a dedicated maintenance, repair, and operations (MRO) team to tackle or prevent asset failure.

MRO often requires the services of field executives, and most businesses use field employee tracking software to manage their mobile workforce.

Dive in to learn more about MRO and the difference between repairs and maintenance.

What is the Difference Between Repair and Maintenance?

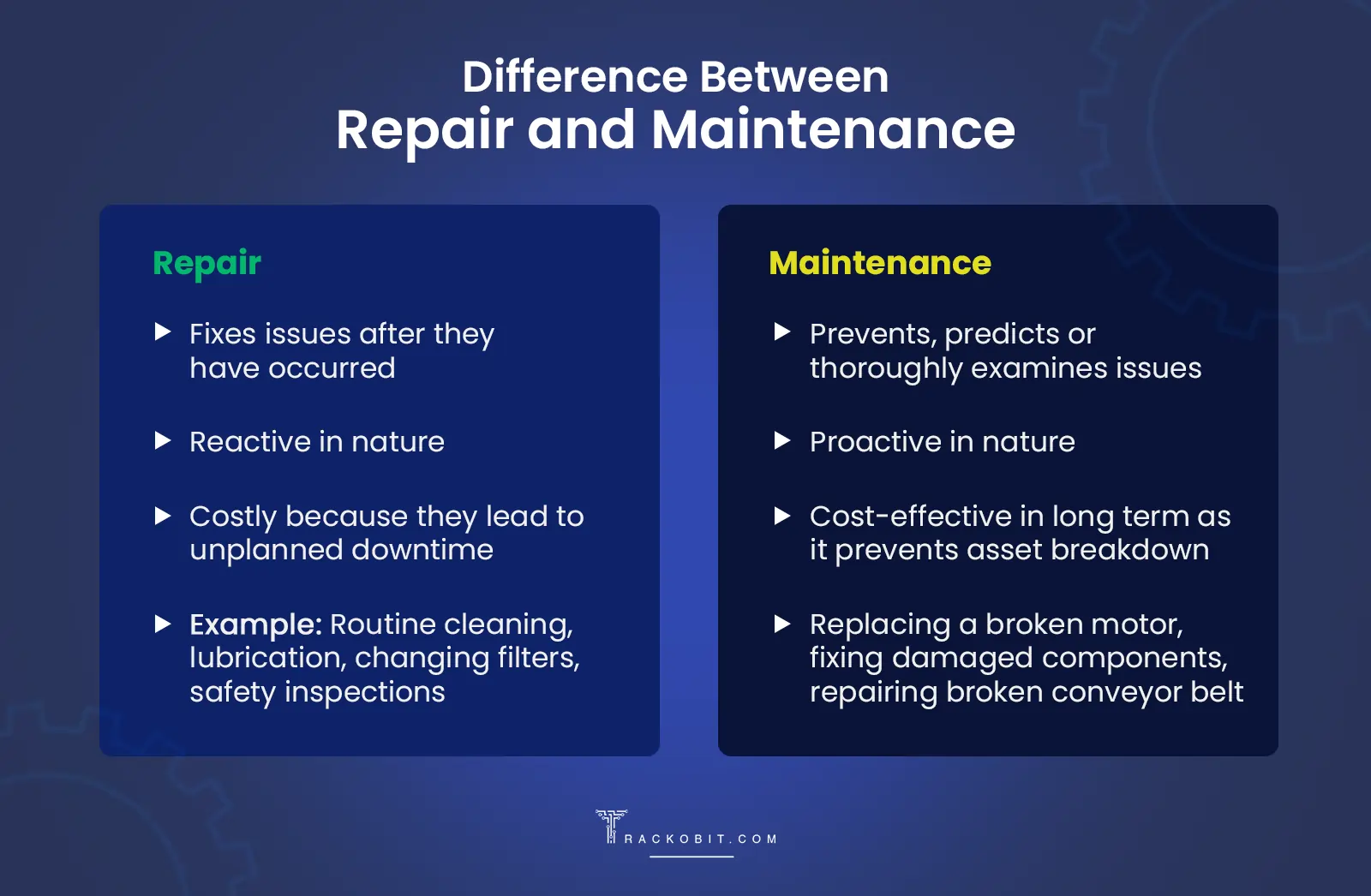

Repair and maintenance are two closely interlinked but distinct processes. Repair can be a part of maintenance operations, but not the other way around. Plus, the latter is a broad term and has several subtypes.

Before we dive in to differentiate between maintenance and repair, it’s important you understand their definition and significance in a business.

Difference Between Repair and Maintenance

Significance of Repair and Maintenance Service in an Organisation

As per Supply Chain Game Changer, MRO expenditures eat up 5-10% of the cost of goods sold (COGS). It may seem like a small number, but when MRO is neglected, the outcomes can be detrimental to the organisation.

Lost productivity, unplanned downtime, and safety threats are just some of the issues that may arise due to poor MRO management.

Now that you’ve learned the importance of repairs and maintenance, let’s understand them individually and find out how field force management software can streamline your MRO activities.

What are Repairs?

Repair is the action taken to correct a problem after it has occurred. In the case of assets, it means returning them to a functional state after complete or partial failure.

1. Complete failure

When an asset stops working or breaks down, it’s a case of complete failure. This results in unplanned downtime and the issues are only resolved through costly emergency measures.

2. Partial failure

It’s a state when an asset is under some degree of working condition despite failing parts. The asset may still require immediate repair and maintenance as it could be unsafe or ineffective to use.

| 💡Here’s an example to understand complete and partial failure:

Imagine you see smoke arising from your air conditioner or hear noises from the fan. The AC may still work even though it will be less efficient at cooling. This is a case of partial failure. But obviously, there is an issue with the AC, and if you continue to ignore it, the AC may shut down. That would be called complete failure. |

What is Maintenance?

Asset failure is inevitable. It’s only a matter of time before your organisation’s assets break down.

However, asset lives can be prolonged and failure can be prevented in most cases. And that’s the core principle of MRO activities in an organisation.

Remember the concept of prevention vs. cure? Repair and maintenance are similarly linked.

Repair is like a cure. It’s more immediate and final. Maintenance is like prevention. It’s proactive and more thorough.

Regular safety inspections, tuning, routine cleaning or lubrication, software updates, and replacing aged machine components are some common activities in the process.

However, maintenance is a much broader term and encompasses a variety of activities. It has three main types:

1. Preventive maintenance

As the name suggests, preventive maintenance is a type of proactive and planned activity that is carried out routinely. Its main objectives are to keep assets functioning optimally, extend their lifespan, and minimise the chances of failure.

This process of repair and maintenance activities includes:

- Routine cleaning and calibration

- Lubrication of moving parts

- Replacing ageing components of equipment

- Performing safety checks on machinery

▶️Here’s an example of preventative maintenance.

In summer, the demand for air conditioners increases and so does their repair. HVAC businesses must prepare in advance to cater to the rising demand for ACs. Thus, having efficient HVAC software grows businesses through the timely scheduling of preventive MRO jobs. They can increase their field technicians, schedule preliminary checks of equipment, offer advanced service of products, etc.

2. Predictive maintenance

Predictive maintenance is used to forecast issues using probability and historical data. It uses machine learning algorithms and data analysis to predict the failure of assets.

Sensors are put on machines to monitor their vibrations, temperature, and battery life. The data is recorded and analysed to predict any anomalies and alert users in advance.

Here’s an example. We know that every battery has a finite amount of charge cycles. Once it cannot hold any charge, there is no other option than replacing it.

With predictive maintenance, you can monitor the battery’s health and anticipate when it will be most vulnerable. This will allow you to keep the battery healthy and take measures before it turns faulty and leads to more serious issues like equipment overheating or failure.

3. Corrective maintenance

Corrective maintenance is undertaken when a product is close to failure or broken down. Although it is similar to repair, the two have major differences.

Repair is like a bandage. It only addresses the issue on a surface level. Corrective maintenance is like a thorough doctor’s examination. It resolves the root cause of the issues and prevents them from recurring.

For instance, if overheating or a faulty part is affecting a machine, then simply performing a repair won’t solve your problem; it will just postpone it. You need to eliminate the main cause of the problem to prevent its recurrence.

Corrective maintenance can be planned or unplanned, and repair can be a part of it, but not vice versa. The process also includes overhaul, salvaging, and reassembly procedures.

Maintenance, Repair and Operations (MRO) in the Field Service Sector

The MRO budget accounts for anywhere between 5 and 40% of the total budget in companies. It’s usually on the higher side in manufacturing, HVAC and facility maintenance sectors. Also, these industries demand the most number of field MRO employees.

Now, tracking desk workers is one thing, but monitoring field employees is a huge challenge for any company.

A field force management software like TrackoField can help you effectively monitor your mobile MRO employees and manage their tasks. Here’s what it helps you do:

- Monitor your MRO technicians in real-time.

- Record their accurate attendance from the service site.

- Assign tasks to them remotely.

- Analyse performance metrics to identify areas of improvement.

- Reduce the first-time fix rate (FTFR) through better task scheduling.

- Improve customer satisfaction with on-time dispatch and allocation to service sites.

All in all, it gives you a single platform where you can assign your technicians and deploy them to the right site with the right tools. And eventually, ensure that every assigned task is done in a defined turnaround time.

Recap!

Let’s go back to the earlier example of dealing with a failing AC to summarise the difference between repair and maintenance.

If you repair the AC when it’s noisy, it’s a case of partial failure. If you repair it when it stops working, that is a case of complete failure.

Predictive maintenance is when you put a sensor on the AC that records its temperature, vibration, noise, etc. to anticipate future failure.

Getting the AC serviced regularly and using it responsibly are activities that come under preventive repair and maintenance.

Corrective maintenance is when you perform a thorough examination of the AC to solve the main cause of the issue.

FAQs

-

What is the difference between repair and replacement?

Repair means when you restore an asset to its original state after failure. Replacement is when you buy a new item in place of the original. If the repair costs exceed 50% of the total cost of the replacement, then it’s advisable from a financial perspective to proceed with replacing the item.

-

What are MRO and capital expenditures in an organisation?

MRO consists of routine activities which are undertaken to fix or prevent problems with an organisation’s assets. Capital expenditures are activities that enhance or expand a company's assets. For example, fixing an old machine is part of MRO. However, buying a new machine to enhance long-term productivity would come under capital expenditures.

-

What is the difference between corrective maintenance and repairs?

Repair can be part of corrective maintenance, but not vice versa. Plus, the latter fixes the asset and thoroughly investigates it for any underlying issues. Repair is a wide-ranging term that means to restore functionality to an asset after its failure.

Mudit is a seasoned content specialist working for TrackoField. He is an expert in crafting technical, high-impact content for Field force manage... Read More

Related Blogs

-

How to Track Field Employees Offline With Field Force Management Software

Mudit Chhikara February 11, 2026Use field force management software to track field employees offline and ensure managers never lose visibility of on-ground operations.

-

How AI-Powered Field Force Management Simplifies Field Operations With Analytical Dashboard

Mudit Chhikara February 10, 2026How AI-powered field force management enhances field operations using AI manager bot and analytical dashboard.

-

Grameen Credit Score and the Quiet Redesign of Rural Lending

Pulkit Jain February 9, 2026Rural lending doesn’t usually go wrong at approval. It drifts when what’s happening on the ground stops being visible.

-

How NBFCs Can Reduce NPAs Using LMS + LOS + FFA Integration

Mudit Chhikara January 30, 2026Here’s how NBFCs can smartly integrate LOS, LMS, and FFA software to reduce NPAs and ensure seamless field operations.

Subscribe for weekly strategies to boost field team productivity.

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.