-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Short-haul Logistics vs Long-haul Logistics

- Author:Drishti Dua

- Read Time:8 min

- Published:

- Last Update: February 4, 2025

Table of Contents

Toggle

Short-haul and Long-haul logistics both have varying operations which means that their challenges also differ. This is why the way they employ Fleet Management Systems also differs.

Table of Contents

Toggle

We know that the logistics industry is one of the largest sectors globally, standing at a value of 227.61 billion. After all, it has so many simultaneous operations that need attention for smooth running. Fleet businesses are important machinery in the running of this industry. But how can these businesses segregate their on-road tasks into several categories?

While there are several ways a business can categorise the nature of its tasks, this blog will focus more on the distance aspect. We will look into ways a fleet management system can help both short-haul and long-haul logistics operate and mitigate challenges.

Long-haul Logistics vs Short-haul Logistics

Categorising a sector as large as logistics can be very difficult. The classification can happen on the basis of various factors. It might be based on the kind of function a fleet/vehicle performs, The fleet business’ size and the distance vehicles cover during transportation.

We can think of two major categories when the classification happens on the basis of distance. These include:

Short Haul Logistics

You might be wondering, what exactly is short haul logistics?

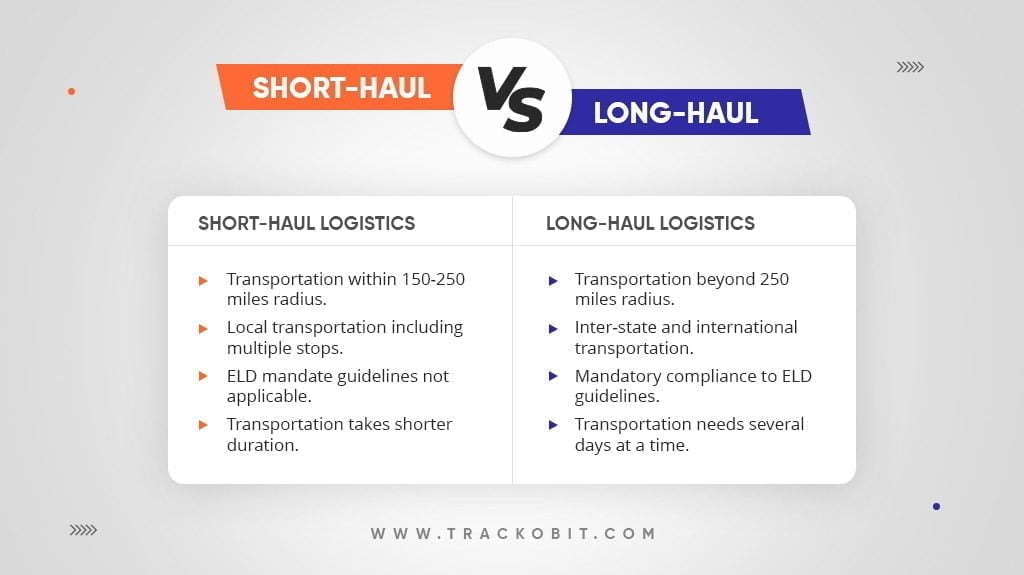

To put it very simply, short-haul logistics vehicles usually operate within a radius of 150-250 miles. Such tasks can be completed in a day and thus, mimic an office job with shifts lasting a couple of hours. Due to its nature, short-haul logistics are limited to local or regional transportation. The transportation process can be between warehouses, between different models, or through multi-stop transportation.

When we look at the American market, the short-haul freight transport market stands at almost 112.33 billion USD in 2022. Even when the logistics industry as a whole suffered during the pandemic, the short-haul industry experienced growth of 0.28%.

In terms of the ELD mandate, short-haul logistics businesses often fall outside of the radar. The mandate requires drivers to log their Hours of Service (HOS) to avoid overworking. But as we discussed earlier, short-haul drivers do not have to spend excess time on the roads and instead work normal shifts. Thus, they have an exemption from the ELD mandate.

Long Haul Logistics

As opposed to short-haul logistics, long haul logistics refers to transportation that goes beyond a 250-mile radius. Thus, it is most visible with inter-city transfers and also plays a part in the international supply chain. When we talk about multi-modal logistics, long haul trucks often become the medium of transporting several different consignments grouped together between logistics parks.

Businesses belonging to the long-haul logistics sector need to ensure compliance with the ELD mandate. With transportation tasks taking several days at a time, it is important to ensure that drivers are not overworked in any way. Thus, recording drivers’ HOS eliminates such risks.

The pandemic hit businesses dealing with long haul logistics the worst. As interstate and international borders closed for transportation, many businesses had to shift their focus to short-haul logistics. But since the borders have opened and the fractured supply chain is recovering, long-haul logistics have also experienced some growth. It is projected to grow at a CAGR of 3% in the US market alone.

Fleet Management System for Short-haul Logistics

We now understand the basics of the short-haul logistics industry. But just like every other sector, it comes with its own set of challenges.

In the time in which we are living, change has become synonymous with technological advancement, hasn’t it? Be it the internet for information transmission, or automated systems, each one is a step to the future we envisioned only in science fiction. After all, data is the oil for change while technology is the driver.

The fleet management system can become the driver the logistics industry requires for optimisation. Let us have a deeper look into each one of the issues that short-haul logistics fleet faces:

Time Sensitivity

Due to the short distances they cover, short-haul vehicles are often expected to transport material quickly. But this expectation fails to consider that distance is just one of the factors determining a vehicle’s travel time. Traffic and road conditions also play a big role in transportation. So how can fleet management systems help vehicles eliminate this issue?

Fleet management software can be very helpful in this process. How? Let us find out:

- Route Planning Solutions: The system provides managers with the option to pre-plan their routes. This means that they can check for any issues on the way and ensure the vehicle does not get stuck.

- ETA: Managers can decide to share their vehicle’s ETA with the customers. This way the clients check the status of their consignment in real time. In case of delay due to circumstances beyond the manager or driver’s control, there will be no need for unnecessary communication between the two parties.

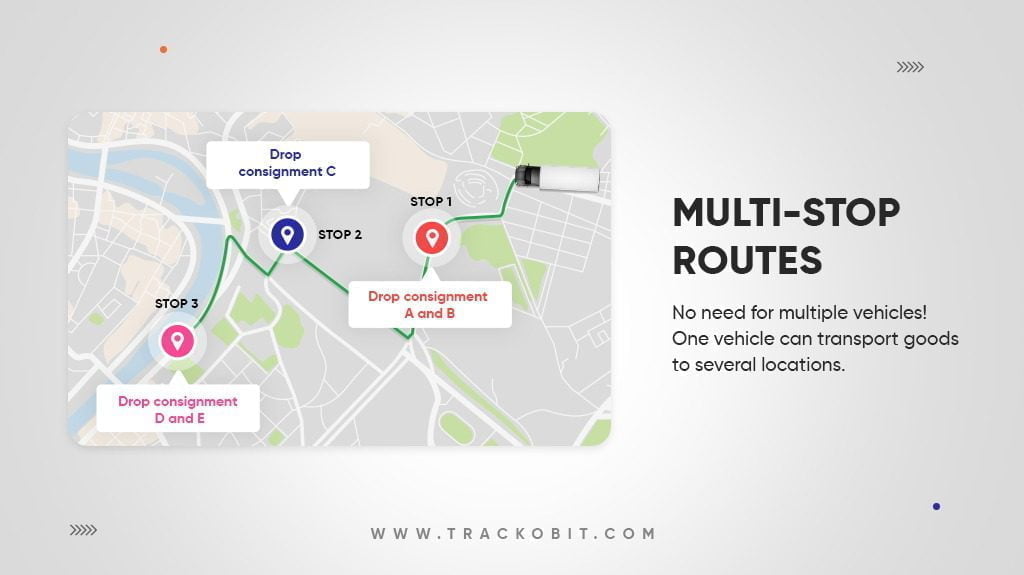

Multi-stop Routes

Short haul logistics mainly deal with local transportation and there is a chance that they have to take consignments to several different locations at a time. But going back and forth between all these locations without any previous planning is just as wasteful as it is expensive. This is where the fleet management software comes in.

The route planning solutions make it easier for managers to handle this task through automation. With a few simple clicks, they can have a trip created. All they have to do is add in the necessary halts and their sequence. The system will create a route covering all these halts.

The system also allows managers to form trips on the basis of vehicle capacity. Thus, the multi-stop transportation trips will consist of halts based on goods that are able to fit in this capacity. The rest can be covered by other vehicles. The process sounds tough, doesn’t it? Well executing it manually is an invitation to stress!

Blind Siding

A vehicle that has to enter and exit consignment facilities several times a day is at risk of collision. After all, the larger a vehicle, the higher its blind spots. This sounds like a pretty trivial matter in theory but can be the cause for not only vehicle damage, but might also harm the goods being transported. Ultimately it is the business owners that will have to compensate their clients for any harmed consignments.

Any form of additional cost to the business is harmful, especially when it costs fleet businesses both money and productivity.

Technology mitigates all forms of challenges though. This is why a video telematics system allows managers to navigate their vehicles better with the help of a multi-camera system. ADAS, i.e Advanced Driver Assistance System, ensures that drivers do not bump/collide with any object while reversing their vehicles (trucks).

Read Blog – operations and benefits of dashcams

Fleet Management System for Long-haul Logistics

We have understood the ways a fleet business can mitigate the challenges faced by short-haul logistics. But are long haul logistics operations problem proof? No, of course not! Even though their challenges differ from that of short-haul vehicles, they also have to spend time and plan ways to prevent any issues during transportation.

Some of the things that fleet businesses need to keep in mind during their fleet’s task completion are:

Overworked Drivers

With a rise in concern over drivers’ working schedules, the governments of both the USA and Canada issued the ELD mandate. According to this mandate, every fleet vehicle dealing with transportation processes outside of the 250 miles radius needs to follow a set of regulations. These regulations ensure the safety of both the vehicle and the driver. It restricted the hours of service a driver put into their work.

The regulation covers two aspects of fleet management, software and hardware. The system is supposed to have a feature where drivers manually enter their login and log-out time. This means that they cannot work to the point of over-exhaustion.

Extensive Wear and Tear

Long time spent on roads without any breaks means constant depreciation of the vehicles. After all, each bump the vehicle encounters leads to some form of damage to the tyres and the engine. To top it all up, a driver’s attitude towards their tasks can also heavily impact how the vehicle looks after a trip. Some of the solutions that help businesses eliminate bad driving practices are:

- Driver Behaviour Monitoring System: Managers get alerts every time their drivers indulge in any harmful or harsh activity. This includes idling, overspeeding, harsh braking, abrupt cornering and so on. Thus vehicle depreciation gets limited, helping the fleet businesses tackle issues like bad engine and tyre health.

- Video Telematics: Having visual data helps fleet businesses ensure that their vehicles do not get into any accidents. Thus, the damage incurred by the vehicle is far less. Collision alerts and other ADAS alerts ensure the vehicle is able to stay in good shape for a lot longer than when unsupervised.

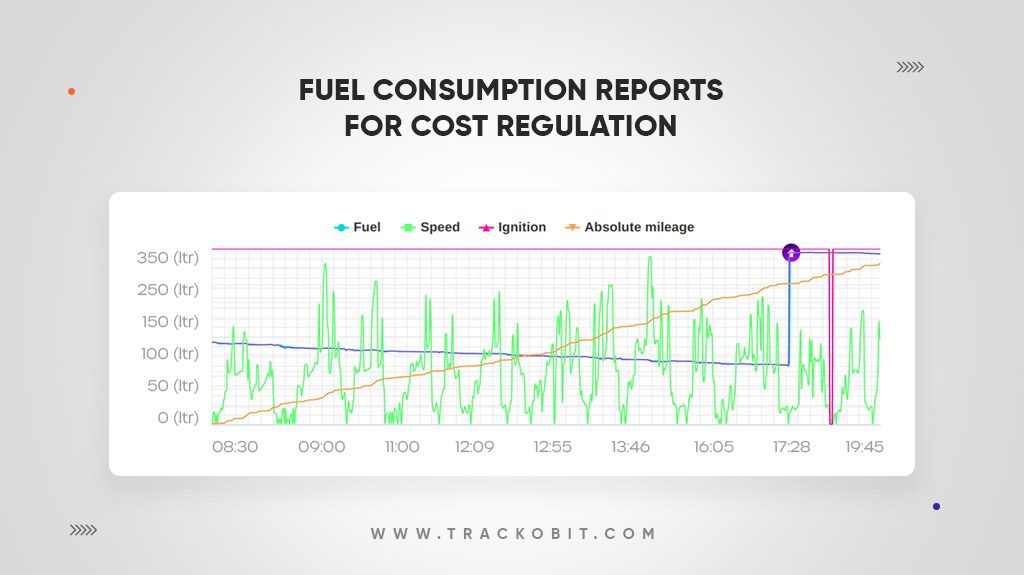

High Operation Costs

There are several extra payments that can plague a fleet business’ budget when they are dealing with large long-haul logistics vehicles. Fuel is the primary example of such operation costs. Large vehicles already consume a lot of fuel to make the situation worse, some drivers indulge in unethical driving. This activity is as bad for the fleet’s health as it is for its fuel consumption.

Pilferage is also a huge factor leading to excess expenditure on fuel. This is why the real-time alert system of the fleet management software allows managers to eliminate such unethical practices. Every time the tank of a vehicle experiences a sudden surge in fuel levels an alert is generated. Thus there is no scope for drivers to falsify receipts for more fuel than spent on the journey.

Drainage alerts work in a similar fashion but eliminate chances of fuel theft directly from the tank itself. This alert also protects the fleet vehicles against fuel loss due to leakage.

Conclusion

The logistics industry is an industry that can be both a profitable opportunity and a money-draining setback. It is the way fleet businesses manage their operations that make all the difference. Well, fleet management software can certainly aid this process! But choosing the GPS tracking software is the primary key to optimisation.

This is why TrackoBit, the leading fleet management system in the world, can become your business’s best friend. With its flexible and useful solutions, your business can get the boost it needs to soar higher. Do not believe our claims? Well, request a demo of the best customisable software in the market and witness how it can help your business grow.

Drishti Dua, a Content Contributor at TrackoBit has a rich background in literature and professional expertise in SaaS and technology writing. She has carved her niche in the space of Geospatial techn... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.