-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What is Pharmaceutical Cold Chain Monitoring? How it Ensures Drug Safety?

- Author:Nandita Gupta

- Read Time:

- Published:

- Last Update: August 20, 2024

Table of Contents

Toggle

Find how pharmaceutical cold chain monitoring systems with continuous temperature tracking and alert systems ensure the safe transportation of temperature-sensitive medicines. Without risking drug efficacy and patient safety.

Table of Contents

Toggle

While dealing with pharma products that require temperature tracking and monitoring — even the tiniest temperature fallout or shortest delay could lead to millions of losses ($35 billion annually).

Pharma companies are now realising that end-to-end visibility is a must-have to monitor drugs and therapeutics with time-tested pharmaceutical cold chain monitoring systems.

Transportation of pharma products from the manufacturer to the patient requires end-to-end visibility; otherwise, there will be:

- Unsafe drugs

- More wastage

- Increased cost

- More lives at risk

What is Pharmaceutical Cold Chain Monitoring?

Pharmaceutical cold chain monitoring involves safe storing, freezing/thawing, transportation, tracking, and delivery of temperature-sensitive medicines in well-refrigerated and ventilated environments. It involves the safe transfer of

- Vaccines

- Temperature sensitive medicines

- Biosamples

- Blood

- Cell and gene therapies (CGT)

It requires strict, uninterrupted temperature control — right from leaving the manufacturer’s testing lab to reaching the dispensary or drug store.

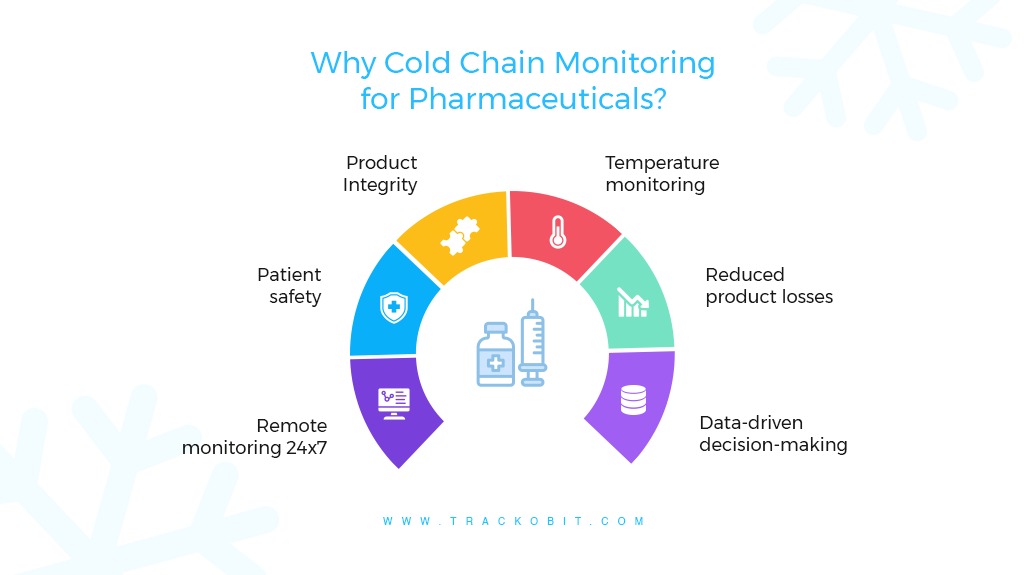

Why is Cold Chain Management in Pharmaceuticals Important?

-

To Deliver Safe Consumables for Patients

If any medicine or vaccine temperature deviates from its recommended level, it can mess up its chemical composition, integrity, and potency. To deliver safe and trusted medication, it’s important to invest in cold chain monitoring solutions.

-

To Cut Losses

| 💡 Do you know a biopharma industry loses approx. $35 billion annually because of failing temperature-controlled logistics? |

Pharmaceutical products worth billions of dollars are still being stored and shipped at poor temperatures. These unfortunate incidents not only make these drugs ineffective or expired but discard the complete batch — adding to financial losses. A cold chain monitoring system can help avoid such losses.

-

Proof during Regulatory Audits

The pharma industry has regular audits by regulatory agencies like MHRA and TGA that verify the data collection process and find any areas of non-conformance on the way. With cold chain monitoring solutions, data pertaining to temperature, humidity level, and transportation is accurately recorded.

Now you know why is cold chain important in pharmaceutical industry, let’s move toward how the whole system works or offers.

Pharmaceutical Cold Chain Monitoring System – How It Works?

Pharmaceutical cold chain monitoring system helps track, manage, and control the safe transfer of pharma products through the supply chain. Let’s see how it works!

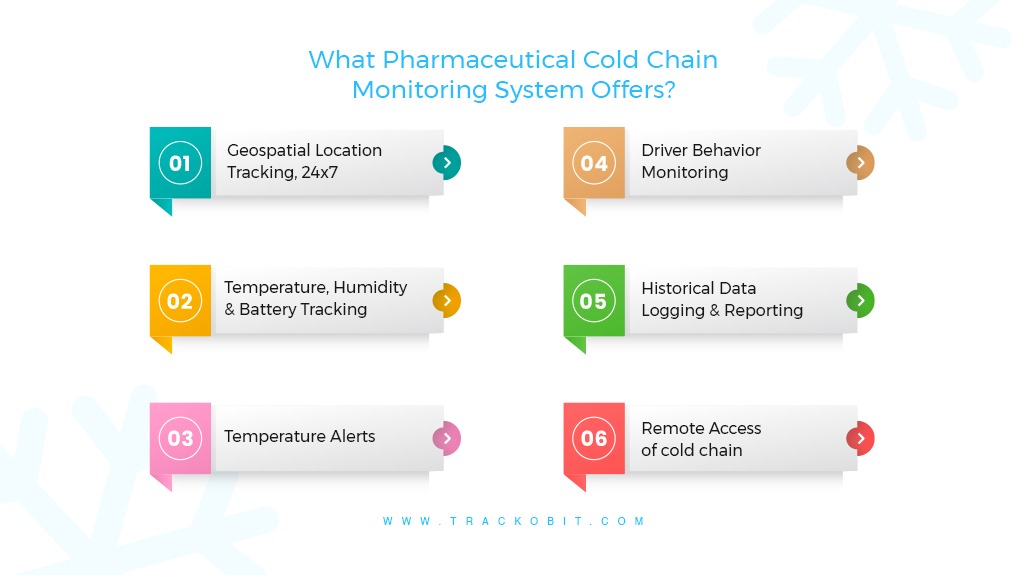

1. Geospatial Location Tracking — 24/7

The cold chain monitoring solutions with the help of GPS trackers receive telemetry readings to identify the present geospatial location of the fleet. Not just location, but you can identify the vehicle speed and routes covered via a live digital map.

The tools used for monitoring the cold chain also help you track and review the locational history of the vehicle for up to 6 months. This helps fleet managers make better data-driven decisions.

2. Temperature, Humidity & Battery Tracking

Temperature monitoring is important for the transportation of temperature-controlled pharma products to ensure their efficacy and longevity. These solutions work in combination with precise and real-time temperature tracking sensors.

These sensors continuously monitor the temperature and humidity level of the storage areas in the fleet. Besides tracking the temperature & humidity level, it also helps track the battery and voltage status of refrigeration units — to replace them before they die.

And in case the temperature or humidity level falls below the prescribed unit, the software immediately shoots alerts to the operator. By using real-time temperature monitors, you can maintain the quality of supplies without meeting financial losses.

3. Insightful Reports

The cold chain monitoring solution generates real-time analytical reports on

- Asset utilisation, hours of service

- Fuel consumption

- Route planning

- Temperature and humidity report

- Driver behavior and performance through visual evidence

-

4. Driver Behaviour Monitoring

Imagine hiring a fleet driver who is negligent, drives rashly, and doesn’t pay attention to the temperature level of refrigerators. Also, it even reaches late at the administration point. Looks like this isn’t what you paid for.

Cold chain monitoring software combined when with driver behaviour monitoring solutions can help keep track of drivers’ driving skills that could impact the timely and safe arrival of pharma products. With the help of special sensors attached to the engine, managers at distance are able to get comprehensive reports around ill driving patterns, such as:

- Harsh concerning

- Harsh Acceleration

- Overspeeding, freewheeling, etc.

Combining the power of temperature monitoring systems with your cold chain fleet will help you mitigate losses and increase your trip’s efficiency.

5. Route Optimisation & Deviation Alerts

In cold chain supply, time is money. A medicine-piled fleet reaching late can be disastrous. It’s important to find the most optimum routes that are short and cost-effective. Route optimisation feature in cold chain monitoring solutions helps drivers identify the most effective routes by assessing over 120+ variables like:

- Traffic

- Weather

- Delivery priority

- Vehicle capacity

- And lots more…

| 💡 Do you know, as per Grand View Research the global cold chain monitoring market size is anticipated to grow at a CAGR of 22.5% from 2023 to 2030? |

Recommended Read:How You Can Master Route Management Challenges?

Top Temperature Sensitive Medications

Vaccines, insulin, biological drugs (such as monoclonal antibodies), or certain antibiotics like ceftriaxone need strict temperature control right from storage and transportation to unloading, to maintain their effectiveness.

| Medication | Required Temperature |

| COVID-19 | 2 to 8 degrees Celsius (36 to 46 degrees Fahrenheit) |

| Insulin | 2 to 8 degrees Celsius (36 to 46 degrees Fahrenheit) |

🔍For temperature-sensitive vaccines, transport partners need to follow storage and handling guidelines provided by healthcare professionals and manufacturers. To maintain the potency of these medicines, temperature monitoring systems cannot go unnoticed.

Get Custom Cold Chain Temperature Monitoring Software!

To ensure the integrity of your pharma products and ensure they reach patients in optimal condition, every time — invest in TrackoBit’s Pharmaceutical Cold Chain Monitoring System.

With real-time temperature monitors and route planning software, precisely track temperature-sensitive shipments to ensure compliance and product safety every step of the way.

| Ready to protect your pharmaceutical investments with our Cold Chain Monitoring system? |

FAQs on Pharmaceutical Cold Chain Monitoring

-

What is cold chain management in pharma?

Cold chain management in pharma involves loading and transporting temperature-sensitive medicines safely, timely, and efficiently from the manufacturing hub to the final place of administration.

-

What are the benefits of cold chain monitoring solutions?

Cold chain monitoring solutions provide real-time temperature insights from any fleet and route throughout the transportation process. This helps bring control, compliance, and efficiency in cold chain fleet management.

-

What's the difference between pharma and food cold chain?

Food Cold Chain Pharma Cold Chain The food cold chain includes the safe handling and distribution of temperature-sensitive food items in a cooling and freezing environment. Safe movement of pharmaceutical products in cool and freezing environments – right from manufacturing to the place where they are finally administered.

-

Why is cold chain important in the pharmaceutical industry?

Cold chain management in pharmaceuticals helps preserve medicine’s efficacy, meet regulatory requirements, and ensure patient safety.

-

How is the cold chain monitored?

The cold chain fleet is monitored through GPS vehicle tracking, route planning, temperature monitoring systems, sensors, and video telematics solutions.

-

Which is one of the best temperature monitoring systems?

TrackoBit provides effective temperature monitoring systems helping with real-time temperature data monitoring to ensure safe storage and transport of temperature-sensitive pharma goods, to enhance product integrity and efficiency.

Nandita is the Team Lead for Content Marketing at TrackoBit, bringing over a decade of experience in B2B, B2C, and IoT sectors. She has a proven track record of helping Read More

Related Blogs

-

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.