-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What is Cold Chain Monitoring and Why is it Essential?

- Author:Tithi Agarwal

- Read Time:7 min

- Published:

- Last Update: December 17, 2025

Table of Contents

Toggle

Cold chain monitoring becomes an indispensable part of the supply chain when it comes to transporting and monitoring time and temperature-sensitive products.

Table of Contents

Toggle

“One rotten apple spoils the barrel.”- Benjamin Franklin.

Are you losing profits and clients due to spoiled bread and dairy products?

Did you know that 14% of the food produced goes stale in transit before it reaches its destination? All this is because of inadequate cold chain monitoring, costing India 14 billion USD annually.

This drives the need for cold chain monitoring solutions as supply chain companies cannot afford such high losses regularly. Through cold chain monitoring software, measures can be taken to prevent temperature and time-sensitive products from going bad, thus causing companies to bear hefty losses.

What is Cold Chain Monitoring?

A cold chain is a constant temperature-controlled supply chain.

It requires refrigeration at every step of the supply chain, right from manufacturing to transportation. The objective behind the cold chain is to preserve temperature and time-sensitive goods from spoiling by maintaining an optimal temperature.

Cold chain monitoring becomes even more vital when it guarantees that the perishable products are transported and stored at the correct temperature and ensures proper handling. At any stage of transportation, they must not be removed from the environment before they reach the customers. Therefore, businesses implementing cold chain monitoring stand to receive real-time information about the product’s condition.

What Industries Use Cold Chains?

A wide range of industries that require keeping products fresh at certain temperatures employ cold chain monitoring.

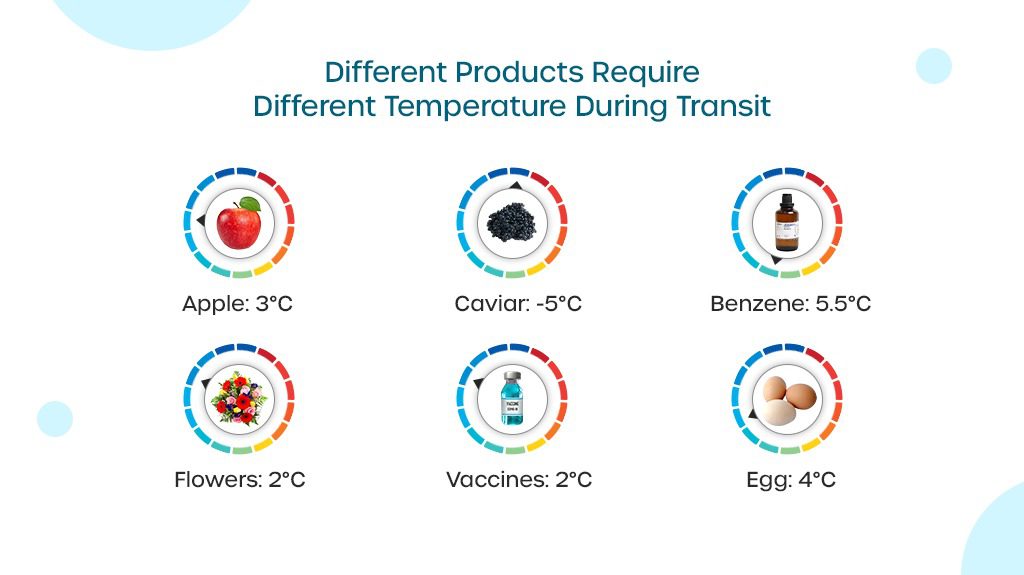

If not preserved and transported at a specific temperature, some products can become undesirable in the market. Thus leading to a decrease in profits. Therefore, monitoring the cold chain is all the more essential for extending shelf life and ensuring that the products are fresh and safe to use.

The Food and Beverage Industry

The food and beverage industry primarily needs monitors cold chain to ensure the products remain fresh, retain their flavour & nutritional value, and elongate shelf life. In the case of frozen food, temperature control becomes even more necessary to avoid the growth of bacteria, maintain texture, and prevent freezer burn.

Furthermore, dairy products such as milk, cheese, yoghourt, and ice cream are highly perishable and sensitive to temperature fluctuations. Cold chain monitoring becomes a saviour for such perishable and short-shelf life products.

Not all products need to be frozen. Some require a chill temperature. For example, fresh berries need to be chilled and not frozen. In fact, freezing them will destroy their texture and shorten their lifespan.

The Healthcare and Pharmaceutical Industry

The global market for healthcare cold chain monitoring is expected to grow at a CAGR of 12.2% by the year 2027. Medical and healthcare components like insulin, vaccines, oncology products, and blood derivatives are susceptible to temperature fluctuation and environmental conditions. Therefore, even the slightest temperature change can be a leading cause of expensive medical vaccines and blood samples going to waste.

But cold chain logistics monitoring provides real-time updates on an asset’s temperature by extracting data from various sensors. This will help prevent the medical components’ effectiveness.

Chemical Industry

Certain chemicals are highly reactive in unpreferable temperatures. Therefore temperature control and monitoring become inevitable. This will help ensure the safe handling of the chemicals and send out alerts in case of temperature fluctuation, which might even ignite a fire.

Floral Industry

Flowers look best when they are fresh and blossoming. But maintaining their colour and freshness to elongate their vase life is a challenge. That can be eliminated through cold chain monitoring. Through proper temperature monitoring and humidity control, the floral industry can now transport English roses and various variants of flowers to remote areas without compromising their beauty.

What Are The Benefits of Cold Chain Monitoring?

Cold chain monitoring will not only help you monitor the temperature and humidity of the refers. But offers many more benefits. Scroll down to know more.

Improves Efficiency

Time is vital for cold chain products, so the capability of streamlining the distribution of refrigerated cargo becomes all the more important. Since it offers entry and exit notifications through geofencing entire process speeds up.

In addition, with the cargo arriving at its destination or checkpoint, managers can check the temperature by monitoring sensor data on the cold chain monitoring software to check for any temperature fluctuation.

Creates a Safer, More Reliable Cold Chain

The transportation and delivery process for such perishable products can be challenging for shippers and consumers when ensuring the good’s efficacy. However, with the proper cold chain monitoring software technology, the chances for temperature fluctuation decrease.

This is because it communicates real-time data allowing managers and drivers to take action in time, thus increasing reliability.

Reduce Product Wastage and Subsequent Damage

Since the goods are susceptible to temperature, humidity, and airborne bacteria, the chances of errors in the cold chain process increase. Everything from refrigerators in the vehicles to vehicles breaking down, unexpected delays can affect the product’s ideal temperature.

But a cold chain monitoring system can help prevent the wastage of expensive cargo. Monitoring temperature through route optimization, real-time location tracking, and refrigerator fleet management.

Prevents Product Delays

Time is vital when dealing with medications, vaccines, and dairy products. After all, delays can cause spoilage and harm consumers. Temperature monitoring decreases the chances of delays. Visibility also allows managers and distributors to make quick decisions in case of vehicle breakdowns or accidents.

Solving Some Of The Major Challenges Of Cold Chain

The rules and regulations of healthcare and food products are constantly evolving, and so is the manner in which the temperature is being monitored.

For example, manufacturers and transporters must work together to tackle the Drug Supply Chain Security Act (DSCSA), according to which prescription products must be tracked to prevent consumers from using counterfeits.

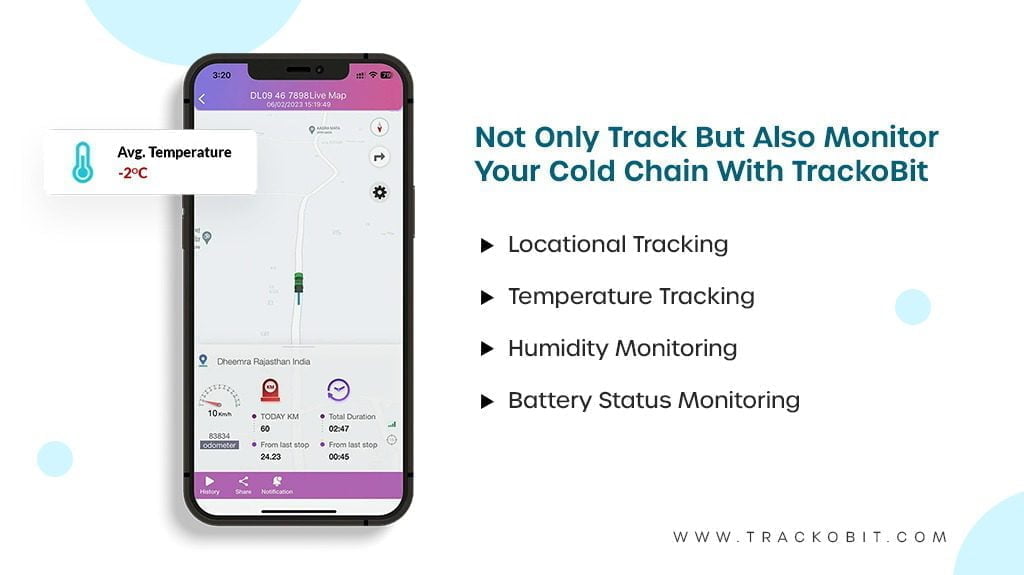

Get a Cold Chain Monitoring Solution with TrackoBit

TrackoBit can be your perfect choice when it comes to cold chain monitoring. We have a reason to say so because TrackoBit not only extracts and shows the information from temperature sensors but can track and monitor humidity levels. It suggests an optimised route and monitors driver behaviour to prevent any damage from coming to the sensitive goods.

Tracking and Monitoring

There is hardly a match to TrackoBit when it comes to tracking and monitoring accurately with next to no downtime. Not only location, but it can track and monitor many other things, most notably temperature.

- Location Tracking: TrackoBit tracks the fleet’s location and even shows the vehicle’s route history with respect to time, health status, etc.

- Temperature Tracking: You are good to go after the temperature sensors are installed in the vehicles and connected with the cold chain monitoring software. The software monitored the temperature 24*7.

- Humidity Monitoring: Maintaining a specific humidity level is required, but the level might vary from product to product. For example, flowers need a high humidity level while being transported, whereas bakery products need a deficient one.

- Battery Status Monitoring: keep track of the battery and voltage status of the refrigeration unit in real-time and prevent them from discharging.

Analytical Reports

The cold chain monitoring software provides comprehensive real-time reports of temperature fluctuations and events in humidity reports. This makes it easy for managers to change the route and make instant decisions.

Route Optimization

In a cold chain, time is crucial; to deliver on time, the companies must employ route planning and optimization. After considering various factors, the software suggests the most efficient, suitable, and shortest route. Additionally, it notifies the managers if the driver deviates from the path.

Driver Behavior Monitoring

Through driver behaviour monitoring, prevent your drivers from harsh braking and speeding, which might squish your delicate tomatoes! The software identifies drivers who need to improve their driving practices and helps differentiate good drivers from bad ones.

Deal With No Spoiled Apple with TrackoBit

Are you looking to deliver fresh mangoes from the south and crisp Kashmiri apples to your customers without worrying about transit spoils?

The answer to it is- cold chain monitoring.

Using it, you can set just the right temperature for your fresh and delicate flowers or fruits.

Not a degree high, not a degree low.

TrackoBit offers cold chain monitoring where you can monitor the temperature and the fleet carrying your temperature-sensitive cargo. And as it offers route planning and optimisation, you can expect your consignment to reach its destination on time and fresh.

Click here to schedule a demo now!

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.