-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Using Fleet Management Software to Maintain Cold-chain Fleets

- Author:Ayushi Nagalia

- Read Time:6 min

- Published:

- Last Update: November 9, 2023

Table of Contents

Toggle

Cold-chain fleets have become a crucial part of the global supply chain. But, maintaining and monitoring them without proper technical aid is nearly impossible. That is why you need fleet management software to make sure that they function the right way and serve the intended purposes.

Table of Contents

Toggle

In today’s globalized world, cold-chain fleets are an essential part of the supply chain industry.

After all, in a world of D2C supply chains and micro-fulfilment deliveries, the FMCG and Pharmaceutical sectors have grown exponentially. And it is these two industries that need cold-chain fleets and cold-chain monitoring the most.

Obviously, the more the need for delivering temperature-sensitive products, the higher the demand for cold-chain fleets. And the higher the need for cold-chain fleets, the more the technical aid is needed to maintain these fleets.

So, what software can help you maintain reefers in transit?

In this blog, let us discusses the essential maintenance procedures for cold-chain fleets and how fleet management software can improve cold-chain monitoring and fleet maintenance.

What Are Cold-chain Fleets?

Here’s the best way to define cold-chain fleets:

Cold-chain fleets are collections of vehicles designed to transport temperature-sensitive products such as dairy items, baked goods, food, pharmaceuticals, and other perishable items.

But what is so special about these fleets and vehicles?

Cold-chain vehicles are equipped with a refrigeration unit to maintain the temperature of the products during transit. The refrigeration unit uses either a diesel engine or an electric motor to generate the cooling effect. The vehicles are insulated to reduce heat transfer and ensure the temperature inside the vehicle remains constant.

According to studies, the global cold chain market is projected to reach $447.50 billion by 2025, growing at a CAGR of 15.62% during the forecast period of 2020-2025. The growth of the industry is mainly driven by the increased demand for perishable items, micro-fulfilment deliveries, and the expansion of the pharmaceutical industry.

These fleets have become increasingly crucial for the current consumer ecosystem and to fulfil consumer expectations. However, they come with a long list of maintenance issues, something that needs to be monitored through specialized fleet management software.

Where and How Are Cold-chain Fleets Used?

Cold-chain fleets are primarily used by the FMCG and pharmaceutical industries. Let us look into how the industries make use of them!

FMCG

To maintain a safe journey of perishable food products from the baker to your kitchen, a lot of things happen in the background. The most important thing that happens is that the supply chain managers have to make sure that these perishable products reach you in time and in good condition through reefers.

In the FMCG industry, cold-chain fleets transport perishable food items such as dairy products, meat, fruits, and vegetables. The use of cold-chain fleets ensures that the products are fresh and safe for consumption when they reach the end consumer.

To keep products fresh and deliveries more efficient, the FMCG fleet industry also heavily uses trip management solutions through fleet management software.

Pharmaceuticals

According to Statista, the global pharmaceutical market size was valued at $1.27 trillion in 2020. Imagine the size of the market we’re dealing with, even if the cold-chain requirements were only 10% of this!

In the pharmaceutical industry, cold-chain fleets are used to transport temperature-sensitive drugs and vaccines. These products need to be stored and transported at specific temperatures to maintain their potency. According to the World Health Organization, the proper temperature range for vaccine storage is between 2°C and 8°C. Any deviation can render the vaccines ineffective, leading to a loss of billions of dollars.

The use of cold-chain fleets ensures that these vaccines reach their destination without losing their effectiveness while saving significant money from going down the drain.

The pharmaceutical industry also heavily uses security measures like eLocks to ensure that these sensitive drugs are not only saved from heating but also from theft.

Problems Faced By Fleet Managers with Cold-chain Fleets

Fleet managers face several challenges when monitoring cold-chain fleets. Some of the common problems faced by fleet managers are:

- Maintaining Temperature: The primary challenge faced by fleet managers is maintaining the temperature inside the vehicle. Any deviation from the required temperature can cause the products to spoil or become ineffective.

- Vehicle Monitoring: Monitoring the temperature inside the vehicle can be a challenge, especially when transporting products over long distances and managers have no clue where the vehicle is. Fleet managers need to know where exactly their vehicles are so that if the reefer malfunctions, they can send help and save sensitive consignment.

- Maintaining the Fleet: Maintaining a cold-chain fleet can be challenging. The vehicles can malfunction anytime, delaying deliveries and risking the consignment’s integrity.

- Managing Costs: The cost of refrigeration units, regular maintenance, and fuel can add up, making it an expensive proposition for fleet managers. While in general cases fuel consumption itself is a huge expense, running cold reefers cross country is a crazy amount of money running on the roads!

- Equipment Management: The refrigeration units require regular maintenance, and any breakdown can result in the spoilage of products. Along with the vehicles, cold-chain fleets come with the responsibility of regular reefer maintenance.

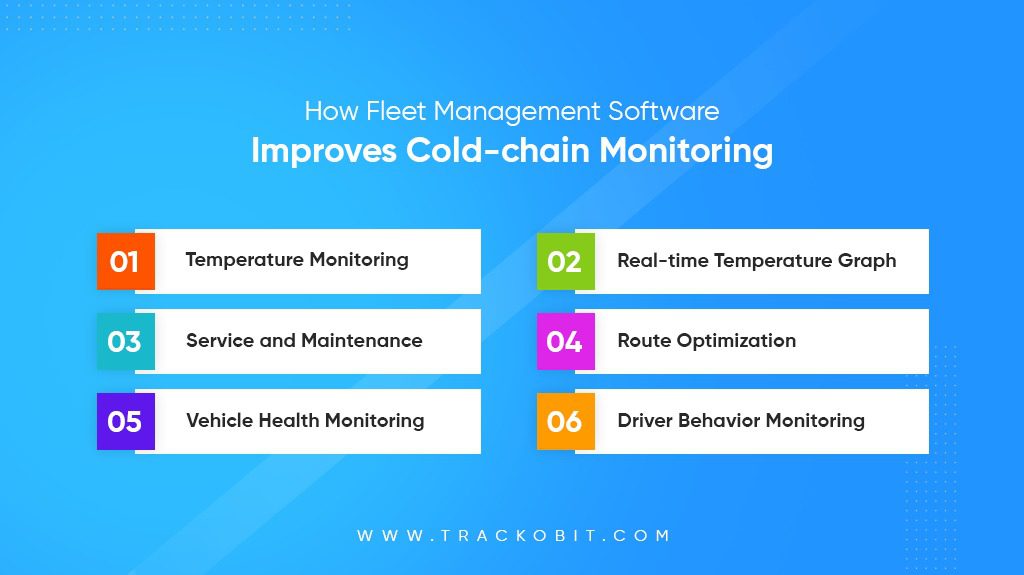

Improving Cold-chain Monitoring and Vehicle Maintenance With Fleet Management Software

Fleet management software such as TrackoBit can significantly improve cold-chain monitoring and fleet maintenance. The software provides fleet managers with real-time geospatial and sensor data to track the location of the vehicle and monitor the temperature inside it.

In this section, let us discuss some ways in which fleet management software helps managers improve cold-chain monitoring.

Temperature and Humidity Monitoring

Fleet management software can help managers continuously monitor the vehicle’s temperature and humidity through data from cabin thermometers. The software can alert fleet managers if there is any deviation from the required temperature, allowing them to take corrective action immediately.

Managers can choose to get emergency alerts when the temperature has gone too high or low, or they can get notifications for any fluctuations.

Real-time Temperature Graph

The best fleet management software like TrackoBit give you a real-time temperature graph of the reefer. Therefore, managers do not have to go deep into the software to see its whereabouts, instead, they can just look at the graph and have a general idea of the reefer’s functioning.

Maintenance Management

Fleet management software can help managers schedule regular maintenance of reefers, ensuring that they are always in top condition. Moreover, the software-generated reports and reefer battery status monitoring indicate when any equipment or vehicles might be glitching.

Regular maintenance can help prevent breakdowns, reducing the risk of spoilage of products. Moreover, regular maintenance will also ensure lower operational costs.

Route Optimization

Fleet management software can help fleet managers optimize the route taken by the vehicle. It can take into account the delivery locations, traffic, and weather conditions to provide the most efficient route.

Route optimization can help reduce fuel consumption, saving costs for fleet managers. Moreover, efficient trip management also ensures that reefers need to stay on the road for the least possible time.

Vehicle Health Monitoring

Fleet management software can monitor the health of the vehicle and the reefers. Therefore, it is great for alerting fleet managers if there are any issues with the engine or other components. Early detection of any issues can help prevent breakdowns and reduce maintenance costs.

Driver Behavior Monitoring

Fleet management software can monitor driver behaviour, providing fleet managers with data on harsh braking, acceleration, and speeding. Avoiding such behaviour is good for fuel saving, vehicle life prolonging, and also ensuring the vaccines or food products don;t smush into each other and go bad.

The software can help fleet managers identify areas where drivers can improve, leading to safer driving practices and lower fuel consumption.

TrackoBit Keeps Your Vehicles Cold and Consignment Fresh!

Cold-chain fleets play a critical role in the transportation of temperature-sensitive products. Therefore, even if the maintenance process is challenging, it is still very giving.

Fleet management software such as TrackoBit can significantly improve cold-chain monitoring and fleet maintenance by providing real-time data on the vehicle’s location, temperature monitoring, and maintenance schedule. So, what are you waiting for? Use TrackoBit to reduce the risk of product spoilage, prevent breakdowns, and save costs!

Ayushi Nagalia is a Senior Content Specialist at TrackoBit. She is a marketing maverick with a lush background in literature. With years of experience crafting content for various niches, she speciali... Read More

Related Blogs

-

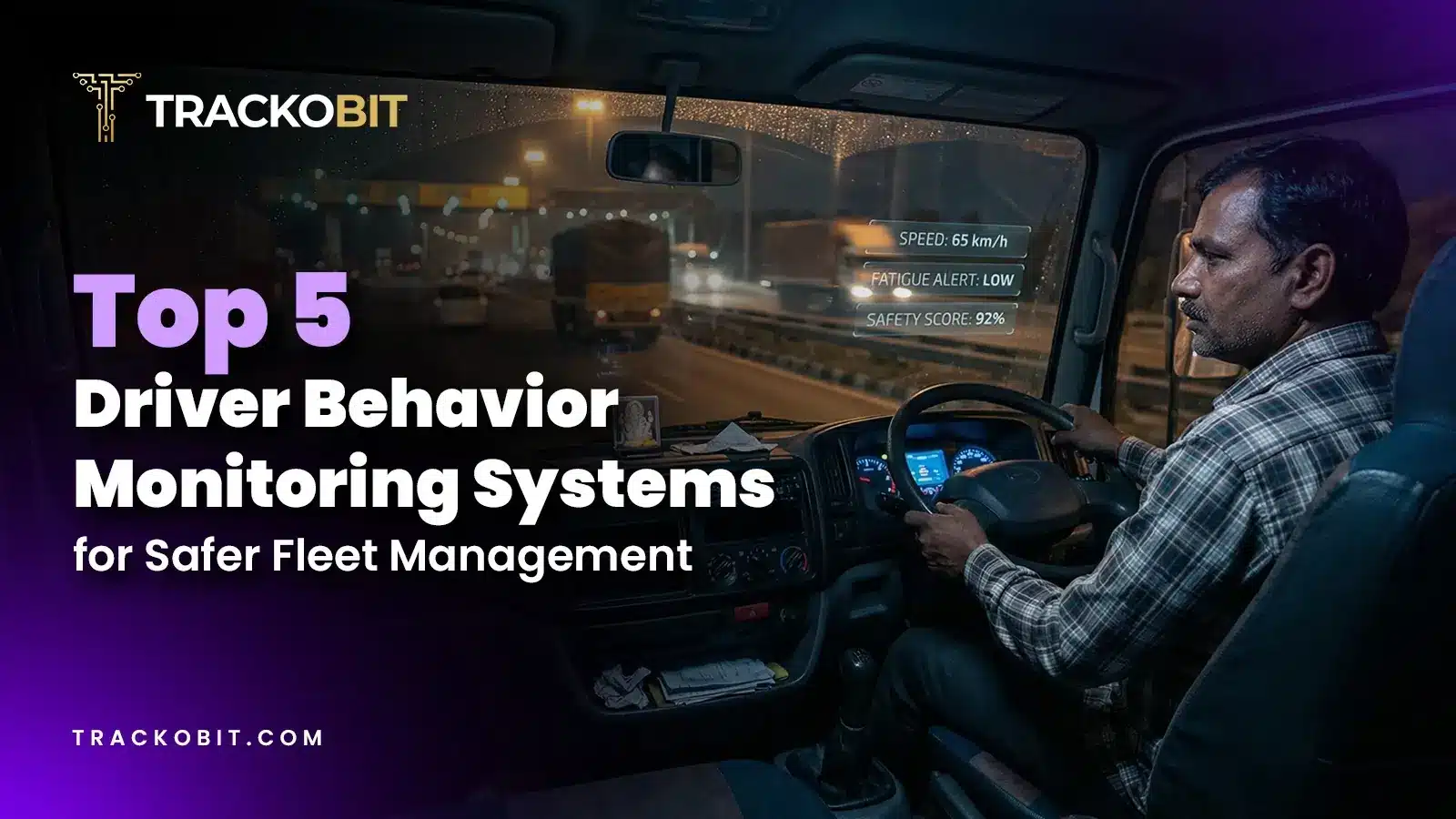

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.