-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Ways to Make Fleet Management Efficient

- Author:Drishti Dua

- Read Time:11 min

- Published:

- Last Update: February 3, 2025

Table of Contents

Toggle

Fleet management requires a lot of planning. This is why managers need to invest in telematics systems to ensure data-based operations.

Table of Contents

Toggle

“Success in management requires learning as fast as the world is changing.” – Warren Bennis

The world of the fleet industry is indeed changing rapidly. This means that the managers working in this industry need to adapt to change while simultaneously maintaining the efficiency! It sure does sound very difficult. Fleet management can make or break a business and this is why we have to look into what role a manager plays in optimisation.

Through this blog, we will be looking at ways that a fleet business can optimise its management process. But before that, we must understand what fleet management means to begin with!

What is Fleet Management?

To understand fleet management, let us first paint the hierarchy of fleet businesses. This will make the managers’ roles and duties so much easier to understand.

The top controlling unit in the fleet business is the owner. They have the authority to make decisions about their fleet and decide the kind of clients the fleet will cater to. It is they who also choose the kind of technologies that will be integrated with their fleet operations.

The worker bees of the fleet are the drivers. Executing tasks and transporting goods is their responsibility. They are also in charge of making on-road decisions after accessing situations. While owners can decide to manage their fleet drivers themselves, some might need an extra helping hand.

Managers are the liaison between fleet owners and drivers. This makes them the primary unit of management of any fleet business. Their job entails operations like monitoring the status of every trip their drivers embark on, planning routes for tasks, ensuring vehicle maintenance, and optimising fuel consumption.

Fleet Management: Ways to Execute it Efficiently

So how do you think a manager ensures that their fleet is not only efficient but also runs without any hiccups? After all, the inability to do so might end up in monetary losses for the fleet business!

Some of the steps to efficient management are:

Assigning Tasks According to Availability

The biggest downside of pairing up a large fleet together with manual management methods is the need for more data and visibility. Managers in charge of a fleet have to assign their vehicle and driver tasks. This step alone takes a lot of planning. Data collection via manual technicians just adds to the problem even more. Not only does it open up a large window for errors, but also causes time inefficiency.

Creating a Maintenance Schedule

Fleet businesses have to focus on their vehicle maintenance just as much. This is why managers are expected to keep tabs on their vehicles’ health and schedule regular checkups for them. But when dealing with hundreds of vehicles together, this process becomes stressful.

Creating a maintenance schedule for vehicles is a good resolution to this problem. While manual management comes with its own set of loopholes, having a schedule to follow can lessen the managers’ burdens.

Employing Sensors

Managers cannot physically monitor each vehicle in their fleet. They are also human after all. Then how can they measure the distance it covers on every trip and its fuel consumption?

Sensors shining through!

These devices can help managers collect data that they can later calibrate and study. Thus, highlighting the pain points of the fleet business and reasons for inefficiency becomes clearer.

Ensuring Fleet Safety

How do you imagine a fleet will be profitable if it is not safe in the first place?

When we count the damages of any on-road accident, the cost goes way beyond simple loss of consignment. Businesses have to look into covering the cost of all the opportunities and productivity lost during downtime. Paying compensation to clients can also add up to be a huge extra expenditure.

This is why managers have to ensure that their drivers follow road safety rules religiously. This can be done by scheduling training sessions for drivers. They are more likely to stay safe on the roads when they have a proper understanding of how their actions affect the fleet business.

Mapping Out Nearby Facilities on Routes

When on the road, a driver needs essential facilities like eating joints, fuel stations, and medical centres frequently. Trying to look for these institutions during emergencies like an accident can not only be time-consuming, but fatal if the situation is severe.

For example, if a vehicle gets into an accident and the driver needs to get to a hospital, then there are two options for the managers to adopt. First, looking for a hospital close by, or having the location of this hospital readily available. This is why managers have to ensure they have the list of all these facilities ready for the drivers.

Technological Tools that Help Fleet Managers

Technology has always been the driver for change and this stands true for fleet management as well. Data-driven operations are all the rage and it is safe to assume that this trend will soon become the norm for fleet businesses as well. So which technological advancements do you think are carrying this change? Well, we have a list compiled for you:

Telematics

With the predictions of 55% of all commercial trucks being connected by 2025, it is safe to assume that telematics has already infiltrated the logistics industry. But what exactly is telematics?

To put it very simply, telematics is the process of transmitting information over a long distance. In terms of fleet management, telematics is used to obtain necessary information about vehicles and work on it for optimisation.

Let us look at an example to understand this better. Suppose a fleet business has vehicles A and B. Both work on five consecutive days and need to go through servicing. But the managers need to have data related to their trips in order to decide what servicing procedures to schedule. If vehicle A had longer routes, its tyres, and engine needed to be tested. Vehicle B encountered more traffic congestion, and the brakes and engine need testing.

Data collection means managers can also develop insights that make decision-making easier for them. This in turn makes the optimising process a lot simpler. It is easier to work on the pain points of a fleet that are backed up by proof than hitting an arrow in the dark, hoping it would make a change.

5G Network Connectivity

When we talk about connected fleets, what do you think is the vehicle of this connection? While there can be several methods of connecting two devices and transmitting information since the introduction of 1G, it has slowly evolved.

The 5G network we experience today is not fast but also has the power to connect more devices than ever before. Sounds like something perfect for fleet businesses, doesn’t it? Having hundreds of vehicles connected on a single platform can make management a lot easier. It also makes operations more transparent for drivers.

Fleet Management Systems

Telematics forms the foundation work for a fully functional fleet management software system. But a lot of elements come together for the software to provide a holistic approach to automation. Automated operations are not only more effective but also make the business trustworthy. The solutions that the system has to offer include:

- Route Planning: Useful in pre-planning routes that the vehicle will take for every trip. Has features like ETA, POD, and geofence to aid this process.

- Driver Behaviour Monitoring: Allows fleet managers to ensure that their drivers are adopting good practices and driving safely. It works on alert systems that tell managers if their drivers are engaging in harmful activities for further investigation.

- Fuel Monitoring: Managers can access their vehicle’s real-time fuel levels. This means that they do not have to worry about pilferage or loss due to leakage.

- Video Telematics: Helps fleet businesses to implement visual-based monitoring with the help of dashcams. They receive alerts accompanied by visual media as proof of distracted driving.

- Asset Tracking: Never lose sight of your consignment via live tracking. This is helpful when engaging in multi-modal transportation. It also helps track all machinery that is separated from the vehicles (like agricultural field machines).

The system helps managers track their fleet drivers, location, and activities in real time. It also uses data to develop insights. Businesses can choose to view these insights on their dashboards themselves, shifting it to an analytical dashboard instead of a traditional one.

The other way is for them to study reports that the system has to offer and drive necessary conclusions regarding their operation’s pain points.

Can Efficient Fleet Management Affect the Fleet Industry?

So how can effective fleet management affect a fleet business as a whole? Let us look at some of the advantages a fleet business gains with an optimised fleet management system:

Efficient Operations

With the help of technological intervention, fleet management can become a very simplified process. The fleet management software brings the perfect combination of automation into the fleet operations. With higher visibility, fewer errors, and better planning, fleet businesses can finally cross the line separating them from profits.

But it is very important to ensure that over-reliance on technology is also not the best for any business. After all, there are some situations and scenarios that require human comprehension to act accordingly. This is where a custom system becomes important. Managers get to choose how much operation needs to be automated and what should be left for manual management.

Better Report Making

We have highlighted the importance of data driven fleet operation above. But is collecting data as easy as it seems? Absolutely not! Having flawless data at one’s disposal requires extensive decoding, categorising, and storing. This is an extremely tedious task when done manually, which is why the intervention of technology is not just an option, but instead a necessity.

The vehicle tracking platform helps fleet businesses collect data and then automatically segregate it into reports. The data collected from the vehicles are in binaries that need the translation before it is of any use to the fleet business. Instead of relying on third-party decoders, the system does the work for managers, and all there is left to do is act on the data thus collected.

Trustable 3PL Execution

The third-party logistics industry is growing steadily. This is because, in this day and age, it is difficult to find the right resources to take care of every single logistics operation under a single company. Several third-party logistics providers are investing in connected fleets and using fleet management systems. But is efficiency the only reason behind this investment?

Of course not! When there is a fleet management system involved with operations, customers have the assurance that their goods are in safe hands. Sharing ETAs and employing PODs add an extra layer of security for goods. Customers have the security of knowing where their goods are.

Safer Intermodal Transportation

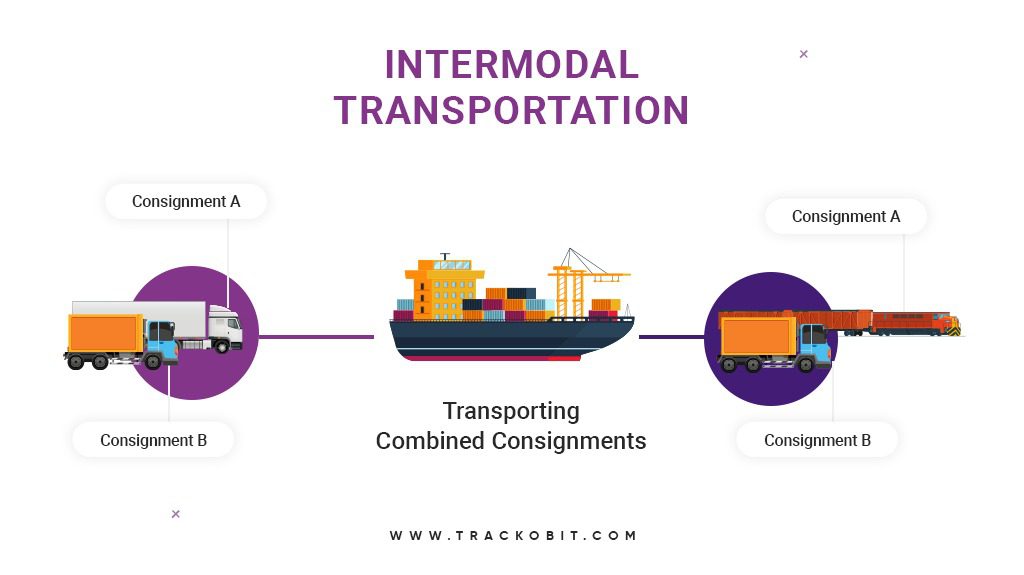

The first question is, what is intermodal logistics? Well, to put it very simply, it is the transportation of goods via more than one vehicle.

For example, two consignments have to be relocated from warehouse A to B. Two trucks will take these goods to a logistics park where they will be clubbed together. A vehicle of greater capacity (Usually large trucks, planes, or ships) will transport these goods together to the logistics park near the desired destination. Finally, two separate trucks will finish the job of delivering these goods to the end warehouse.

With the help of GPS tracking systems, it becomes easier for managers to keep track of their goods. Asset tracking can also be helpful in this process. Clients having access to their consignment’s location do not have to worry about pilferage or misplacement.

Easier Sensor Integration

Sensors play a very important role in the operations of any fleet. Right from thermometers to fuel sensors, these devices have the responsibility of transmitting data to managers regarding their vehicles.

The telematics system has a big role to play in this process. But how is this beneficial to the fleet business? Let us understand taking a few varying sensors into consideration:

- Load Sensors: This sensor helps managers know the exact weight of the goods that a vehicle is carrying. Thus, eliminating the need for weighbridges in any industry. With this data, managers can ensure their vehicle never has to be subjected to depreciation caused by overloading.

- Door Sensors: Safety is the top priority for several fleet businesses. This safety can be related to vehicles, drivers and consignments. To ensure that no good falls off a vehicle in transit, door sensors can be the best option. Wherever the door is opened, managers get alerts and they can investigate the reason behind this alert.

- Thermometers: For cold-chain supply, it is essential to integrate reefers with vehicles. But managing these reefers can be another giant altogether. Thermometers make sure that the temperature inside the reefers is ideal as constant fluctuations can damage the perishable goods/medicines the fleet is responsible for.

Lower Carbon Emission

While profitability is a huge factor that fleet businesses have to base their management around, their responsibility towards the environment also needs to be a top priority. But how can sustainability prevail in an industry that operates on fossil fuels?

Some food for your thoughts isn’t it? While the shift to EVs is something we can envision for the future, there is still a long way to go before that becomes a well adopted practice for fleet businesses. This is why the next best option is to regulate their fuel consumption. And the fuel monitoring system can be a godsend for this journey.

From tracking fuel levels of vehicles to regulating where a driver purchases fuel, this system can efficiently tie together all loose threads that might be leading to wastage.

Choose TrackoBit as Your Fleet’s Best Friend!

Yes, investing in a fleet management system can certainly help. But choosing what software you integrate with your operation is what sets you apart from the crowd. So the choice is yours. Do you want a common system that performs all the common functions, or do you want a custom-built system that has solutions specially catered to your needs?

It is the second option, right?

This is why TrackoBit is certainly the best choice for your fleet business! With robust solutions and unrivalled compatibility, it is one of the most sought-after systems in the industry. Instead of writing a paragraph to tell you how the system can transform your fleet business, we simply invite you to experience the change first-hand.

Request a demo and watch it in action yourself!

Drishti Dua, a Content Contributor at TrackoBit has a rich background in literature and professional expertise in SaaS and technology writing. She has carved her niche in the space of Geospatial techn... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.