-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Why Every Drop Counts in Fuel Management for the Mining Industry

- Author:Ayushi Nagalia

- Read Time:5 min

- Published:

- Last Update: December 17, 2025

Table of Contents

Toggle

Did you know that mining trucks can consume about 350 liters of diesel per hour? That is about 150 times higher fuel consumption than an average sedan!

Table of Contents

Toggle

What’s more, these haul trucks are not the only vehicles consuming fuel on a mining site. From bulldozers, loaders, and mining trucks, the average fuel consumption on site is tremendous!

Every single drop in the mining industry counts as it is one of the most fuel-guzzling industries. Therefore, GPS tracking software in fuel monitoring used in the mining industry needs to have exemplary fuel management systems.

An Understanding of Fuel Consumption in the Mining Industry

Fuel consumption is the primary operational cost for most mining fleets. Even the smallest of fuel adjustments can result in massive savings. For example, even if your fleet saves merely one-liter diesel per hour per truck, you will save 16,800 liters in a week for a fleet of hundred mining trucks! That is 67,200 liters a month for a small mining fleet.

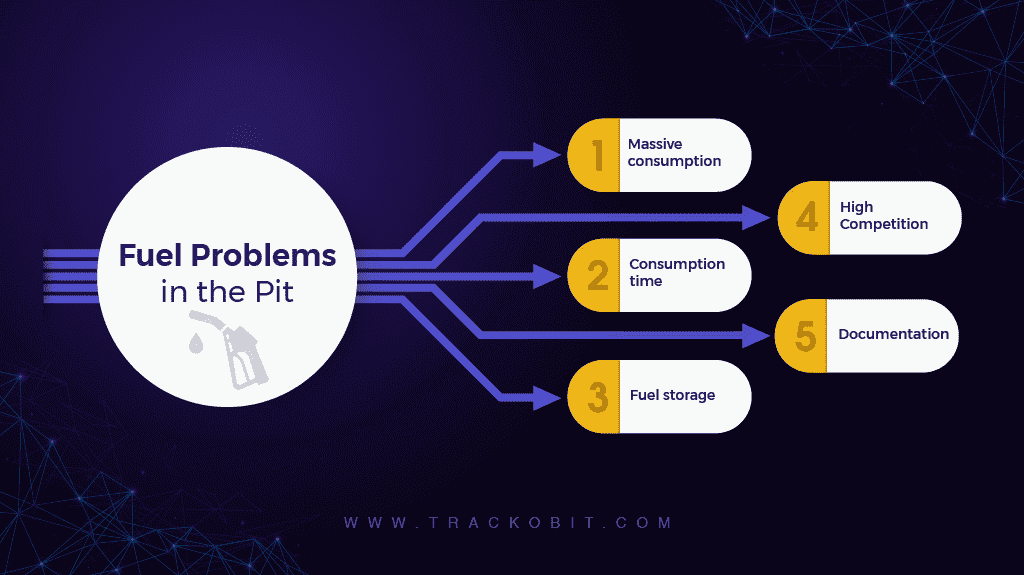

In this section, we’ve explained some fuel-related factors affecting the mining industry.

Massive Fuel Consumption

8,400 liters of diesel! That is how much fuel one mining truck consumes in a day. And a mining fleet consists of several of them along with other equipment that needs fuel on run.

While vehicle acquisition is expensive, it is at least an investment. Fuel consumption, however, is a one-time yet continuous expenditure that affects the fleet economy. Using the right kind of engines and fuel-saving techniques is the way to go here!

Consumption Time

On one hand, mining trucks partake too much. Secondly, they do it all the time.

A mining fleet runs every hour of the day throughout the week. Mining is a continuous process and hence, the fleet can never rest. Even though they work in shifts, there are always a minimum number of vehicles at work on a mining site.

With the kind of fuel consumption each equipment and vehicle has, the constant running only makes consumption heftier.

Fuel Storage

If there is one thing more extensive than the rate of fuel consumption in a mining fleet, it is the fuel storage! Imagine the amount of fuel that needs to be stored on a mining site at all times. And this is a huge problem for four reasons:

- Fuel is highly flammable. Hence, you cannot risk storing extra on a mining site where chances of mishandling are high.

- Running out of fuel means sucking the lifeblood out of operations. Lack of fuel will be even more costly than buying the required fuel.

- Mining sites are always in remote areas. Therefore, any shortage is hard to mitigate in an emergency.

- Mines are generally run by two managers working on different shifts. Without proper supervision and documentation, the threat of fuel running out due to mismanagement is pretty strong.

Low Margin Competitiveness

Other than the massive fuel consumption, a mining truck can incur a minimum expense of $40,000-$50,000 for a single tire change. Therefore, the mining business is extremely competitive when it comes to operating costs.

Fleet managers generally have to do whatever they may to reduce those costs to attain profitability. However, the biggest expense, i.e. fuel cannot be dramatically cut down.

How GPS Tracking Software Saves Fuel

Fluctuating prices of resources and mined products make using GPS tracking software a mandate. They help optimize operational costs and efficiency. GPS tracking software for a mining fleet needs some specialized tools and features to make ruggedized hardware’s functioning seamless.

Fuel Consumption Reports

The best use of fleet management software in the mining industry is analyzing and appropriately using the fuel consumption reports. These reports keep a complete account of when and how fuel was used by your vehicles.

Good software such as TrackoBit represents this fuel consumption data in digestible visual representation.

Here are a few benefits that come with fuel consumption reports:

- You get data and statistical information about when your site will need another fuel refill. This is because you will have complete information on how much fuel your entire fleet is consuming.

- When you employ fuel-saving techniques, you get to check in real-time if any step is making progress in reducing fuel consumption.

- You can generate a much more accurate budget concerning the amount of fuel your fleet consumes. No more do you have to rely on guesswork!

Complete Diagnostics

If your vehicle’s engine is not in good shape, it is bound to consume more fuel. Therefore, you always need to make sure that your vehicles’ engines are at their optimum performance capacity.

With the right hardware integration, your fleet management software will look into the nitty-gritty of how your vehicle is performing. Therefore, you get to maintain and work your trucks most efficiently if the diagnostics reports suggest otherwise.

This is the best way for you get to save unnecessary fuel consumption in your fleet.

Total Documentation

Everything that goes on in your fleet is neatly documented in your fleet management software. From engines’ activity hours, efficiency, and productivity to fuel capacity, consumption, and employee records.

When everything is documented neatly in the software, the chances to miss out on timely fuel acquisition and other important operations fall drastically. Moreover, the more data you have in your software, the better the reports it will generate, helping you with further fleet management.

What Else Will GPS Tracking Software Do?

Fuel consumption is a pressing topic in mining fleet management. However, there is so much more than fleet management software that will help your mining fleet with:

- Multiple Site Tracking: Software will connect all your vehicles and employees in a way that handling multiple sites will be easy. You can relocate and monitor equipment anywhere, any time without hassles.

- Avoiding Engine Fatigue: Software can monitor engine hours and can also check for signs of fatigue in the engine. Always keep your fleet in good shape by strategically using this information.

- Prioritizing Assets: With real-time vehicle tracking systems, your vehicles and employees will always be safe. Features such as SOS alarms help increase safety in your fleet.

- Defining Emergencies: TrackoBit can send about 50 custom alerts from idling to geofence entry/exit. You can choose the situations you will deem as emergencies and you’ll get notifications accordingly.

Leave Your Competition in the Pit!

Yes, massively reducing fuel consumption in a fleet might not be possible. However, by taking some fuel-conscious steps, you might be able to reduce wastage in your fleet.

With fuel prices in constant flux, managers need to be careful of their fleet’s fuel requirements at all times. So, what are you waiting for? Use TrackoBit, India’s fastest-growing telematics software to increase efficiency and productivity in your mining fleet. You will certainly not be disappointed with our white-label fleet management software.

Ayushi Nagalia is a Senior Content Specialist at TrackoBit. She is a marketing maverick with a lush background in literature. With years of experience crafting content for various niches, she speciali... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.