-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Prevent Vehicle Breakdowns with Data: Advantages of Telematics

- Author:Anvesha Pandey

- Read Time:8 min

- Published:

- Last Update: December 11, 2024

Table of Contents

Toggle

Vehicle breakdowns are a constant challenge, but what if you could prevent them? A data-driven approach helps proactively tackle breakdowns. Read on to discover how.

Table of Contents

ToggleAs a business owner, every breakdown is not just a mechanical failure. In fact, it’s a loss of time, loss of money & in most cases loss of reputation.

But what if your vehicles could tell you exactly what they need? Long before a breakdown happens.

Telematics solutions do just that! The solution leverages a data-driven approach to streamline vehicle maintenance. From preventive maintenance analytics to scheduling maintenance, they help flag potential issues.

This piece unfolds how telematics and fleet maintenance go hand in hand. Followed by how this data-driven approach can transform your operations.

So, let’s get started with the basics!

What are Vehicle Breakdowns?

Simply put, a vehicle breakdown refers to the failure of a motor vehicle. Vehicle breakdowns can occur due to various reasons:

-

engine problems

-

battery failures,

-

electrical malfunctions,

-

flat tires or blowouts

Breakdowns are hard to predict. They lead to operational disruptions, more overheads, and delays. Thus, regular inspections and proactive maintenance are a must.

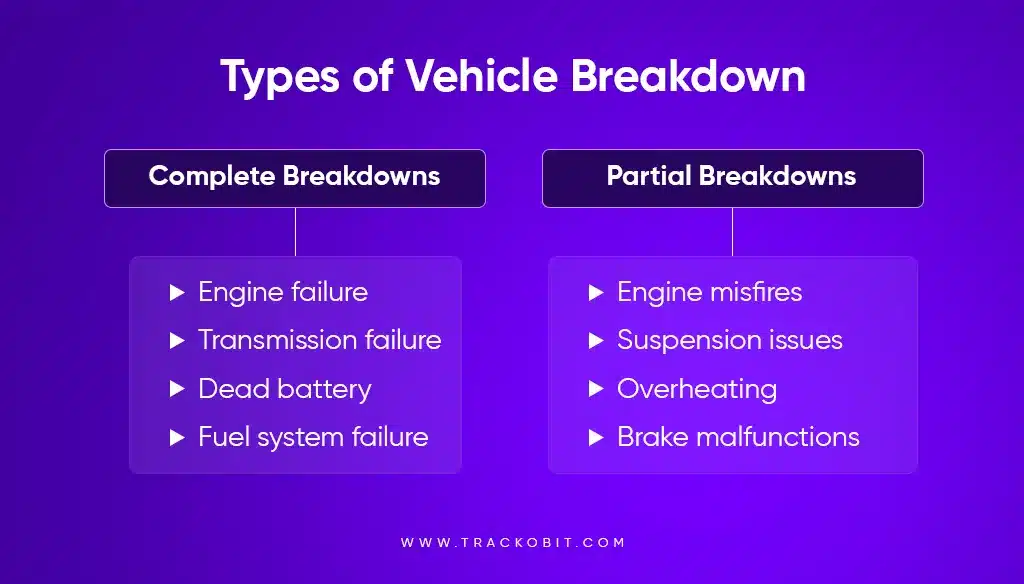

What Are the Different Types of Vehicle Breakdowns?

What are the different types of vehicle breakdowns

Vehicle breakdowns can be classified into two types i.e.“Complete” and “Partial”. These two types differ based on the level of disruption they cause.

Let’s unfold both types individually.

1. Complete Breakdowns

A complete breakdown occurs when the vehicle becomes entirely inoperable. It often leaves it stranded on the road. Such situations demand immediate repair or towing assistance.

These breakdowns are typically caused by severe issues in critical components. They can be in the form of engine failures, or complete fuel system malfunction.

2. Partial Breakdowns

Partial breakdowns, on the other hand, allow the vehicle to continue operating. But the catch is they operate with limited functionality.

It is less severe than complete breakdowns. However, they still need timely attention to prevent further damage.

Common examples of partial breakdowns include engine misfires and transmission slipping.

Having insights into big data can be the best solution to avoid vehicular breakdowns. Read what role telematics data plays in fleet management.

The Role of Telematics Data in Fleet Management?

Geoffrey Moore once said, “ Without big data, you are blind and deaf and in the middle of a freeway.”

Big data plays a crucial role in fleet management and preventing vehicle breakdowns.

Telematics solutions leverage big data to track important metrics. These metrics can be driver behavior, vehicle health, etc.

It allows you to track events of malfunction spot on. It allows you to track events of malfunction that could lead to severe breakdown.

1) Real-Time Alerts for Immediate Action

You receive immediate alerts whenever telematics sensors detect critical issues like

-

Overheating

-

Low Battery Voltage

-

Rapid Tire Pressure Drops

With the help of these notifications, fleet managers can respond swiftly.

2) Engine Health Monitoring

The telematics solution continuously monitors the engine performance by tracking various parameters like-

-

Oil Pressure

-

Coolant Levels

-

Fuel Efficiency

Continuous monitoring allows early detection of any potential issues. This also makes it easier for you to schedule maintenance.

3) Battery and Electrical System Monitoring

The electrical system is critical to vehicle operations. Telematics solutions for breakdowns allow you to monitor various parameters like-

-

Battery Health

-

Alternator Performance

This proactive monitoring helps ensure that the electrical systems are functioning properly. Additionally, gauging this reduces the risk of sudden breakdown due to power-related issues.

4) Tire Pressure and Temperature Monitoring

Maintaining optimal tire pressure is essential for both – safety & vehicle performance. Telematics solutions help you

-

Monitor tire pressure

-

Track tire pressure

Wondering why to gauge this parameter?

This is because having a track of tire conditions helps you ensure whether the vehicles are operating efficiently or not. Further, this also helps avoid accidents or delays caused by tire failure.

Telematics solutions provide you with real-time data & preventive insights into the vehicle’s health.

Steps to Use Telematics Solutions to Avoid Vehicle Breakdown

Implementing a data-driven approach to vehicle breakdown management requires a structured approach. These strategies include gathering, analyzing, and acting on relevant fleet data.

Here’s a step-by-step guide to achieve this-

STEP 1- Defining Objectives and Important Key Metrics

The first step includes gathering historical data from multiple sources. Your sources can include vehicle sensors, telematics devices, and DVIRs.

Gathering all this data sets the stage for a focused and effective approach to better vehicle breakdown analysis.

STEP 2- Implementing Telematics Solutions for Breakdown Analysis

Use a telematics solution that integrates with OBD (On-Board Diagnostics) devices. This helps to capture real-time vehicle health.

Additionally, you can enable the collection of fault codes (DTCs). These codes, along with other indicators, can signal an impending breakdown.

STEP 3- Centralize Data in a Fleet Management System

Deploy a robust fleet management system to fetch data from various servers to a central dashboard.

Doing this will provide you with easy access to real-time and historical data for each vehicle. You will have quick access to health and performance metrics.

STEP 4- Conduct Regular Data-Driven Inspections

Shift from relying solely on fixed maintenance schedules to dynamic, data-driven inspections. Use vehicle data to identify parts showing early signs of wear or faults . Further, prioritize those vehicles for maintenance.

For instance, if the data shows wear on certain parts of any vehicle, prioritize them first.

STEP 5- Implement Real-Time Alerts and Notifications

The next step involves configuring the telematics solution with alerts & events. Telematics sends real-time alerts for issues like engine overheating or tire pressure drops.

You can also set thresholds for alerts and prioritize notifications. Especially the ones that require immediate action.

STEP 6- Analyze Data to Identify Root Causes and Trends

You can use telematics solution to review breakdown incidents in detail. It helps identify common causes related to specific models, routes, or operating conditions.

Additionally, you generate reports to analyze breakdown patterns and uncover the root causes. This proactive, data-driven approach helps boost vehicle uptime to prevent breakdowns.

Insights into some numbers!

Benefits of Telematics Solution for Vehicle Maintenance

The benefits of telematics in managing vehicular breakdowns are endless. It can potentially minimize and manage vehicle breakdown risks.

Below here is a showdown of the wonders that big data brings to the table.

1. Preventive Maintenance

It’s proven that fleet telematics solutions help with preventive maintenance. A data-driven approach enables fleets to shift from reactive to proactive maintenance strategies. Data can reveal early signs of potential issues. This is done by monitoring vehicle performance through telematics solution.

This lets you address minor problems before they escalate into major breakdowns.

2. Cost Savings

One of the most significant advantages of adopting a data-driven approach is cost savings. With real-time monitoring and analytics, you can identify problems. Further, avoiding expensive breakdowns & emergency repairs.

This means fewer expensive emergency repairs, less downtime, and lower towing costs.

For Example- Replacing an engine can cost $4,000–$10,000, depending on the vehicle type.

However, with telematics solutions, it’s easy to flag minor issues like overheating or oil pressure drops early. This allows for proactive repairs, which typically cost only $200–$500.

Hence, having a data-driven approach helps save thousands in replacement costs.

3. Enhanced Vehicle Lifespan

Vehicles that receive timely and tailored maintenance are more likely to last longer and perform better. Regular, data-driven maintenance ensures that vehicles are optimally assigned and utilized

4. Comprehensive Insights

A data-driven approach provides fleet managers with a treasure trove of insights. This offers a deeper understanding of vehicle performance and maintenance trends.

Therefore, by consolidating data from multiple sources. You can uncover patterns and recurring issues.

Bottom Line

“Without telematics solutions, gaining actionable insights into fleet data becomes much harder.”

Telematics makes it easy to gauge vehicle performance. It even detects signs of malfunctions early on. It gives you min-to-min actionable data that reflects your vehicle’s health. Not just that, it helps you create optimized and safe trips where you save on time and fuel spent too.

If saving big on costly repairs is your goal, TrackoBit’s fleet management software is for you. The solutions are powered by telematics and geospatial data. With features like route planning, and driver behavior monitoring, it makes everything efficient.

Remember,

The More Detailed the Insights, the Better the Fleet Performance.

Get in touch today!

FAQs

-

How to avoid vehicle breakdown?

Regular maintenance, timely inspections & using telematics solution for diagnostics. These are some of the ways you can avoid vehicle maintenance.

-

What to do when a vehicle breaks down on the road?

Ensure safety, alert roadside assistance, and communicate delays with stakeholders.

-

How to manage vehicle breakdowns commercially?

Implement preventive maintenance strategies. Use telematics solutions for alerts, and maintain an on-call repair team.

Anvesha is a communication specialist at TrackoBit. With a strong background in media and communications, she adds much-needed balance and brevity to TrackoBit’s... Read More

Related Blogs

-

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.