-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

What are DTC Codes? Types & How to Decode Them

- Author:Tithi Agarwal

- Read Time:8 min

- Published:

- Last Update: February 4, 2025

Table of Contents

Toggle

Do you see a blinking check engine light but don’t know what it means or the reason? In this blog, we will learn why deciphering DTC codes is crucial for identifying the issue.

Table of Contents

Toggle

If you manage a fleet, staying on top of any engine or other vehicle issues is critical for the safety of your drivers. As it also helps prevent more costly repairs.

This is where Diagnostic Trouble Codes (DTC) come in — codes that a vehicle’s onboard computer relays about any potential issues.

How do these codes work, and how do you decipher them? Most importantly, how can you gain remote access to them for your fleet?

This article will explain DTC codes and how to interpret them. We’ll also look at how you can manage the maintenance of your fleet with fleet telematics.

Keep reading to learn more.

What is a DTC Code?

DTC stands for Diagnostic Trouble Codes.

A DTC code is a series of diagnostic trouble codes used by a vehicle’s onboard diagnostics (OBD) system to alert you when a vehicle experiences a malfunction. Different codes have different meanings and represent specific problems in your vehicle.

When the vehicle’s OBD system detects a problem, it generates a specific DTC code and transmits the alert to the vehicle’s instrument panel as a warning light. In vehicles equipped with a telematics system, the alert can be delivered directly to the fleet. The system can also be set up to send the alert directly to the maintenance department.

The Society of Automotive Engineers (SAE) created these codes to help vehicles comply with emission regulations.

Types of DTC Codes

Comprehending every DTC code on your vehicle can be challenging because many generic and manufacturer-specific ones could appear.

DTC codes can be categorized into two types:

Type 1: Critical codes

These urgent DTC codes can cause quick and severe damage to the vehicle.

DTC codes such as high engine temperatures and low coolant levels could mean that engine failure is sure to happen. With real-time vehicle diagnostics, fleet managers and technicians can act quickly. They can assess the severity, recommend appropriate action immediately, and locate the nearest service center or garage. This will aid in resolving the issue before it becomes costly and critical.

Type 2: Non-critical codes

While these DTC fault codes do not need urgent solutions, they still require proper attention. This includes emissions-related engine DTCs that don’t lead to excessive pollution.

Non-critical codes include those that light up the Malfunction Indicator Lamp (MIL), also known as the Check Engine Light.

How to Decode DTC Codes

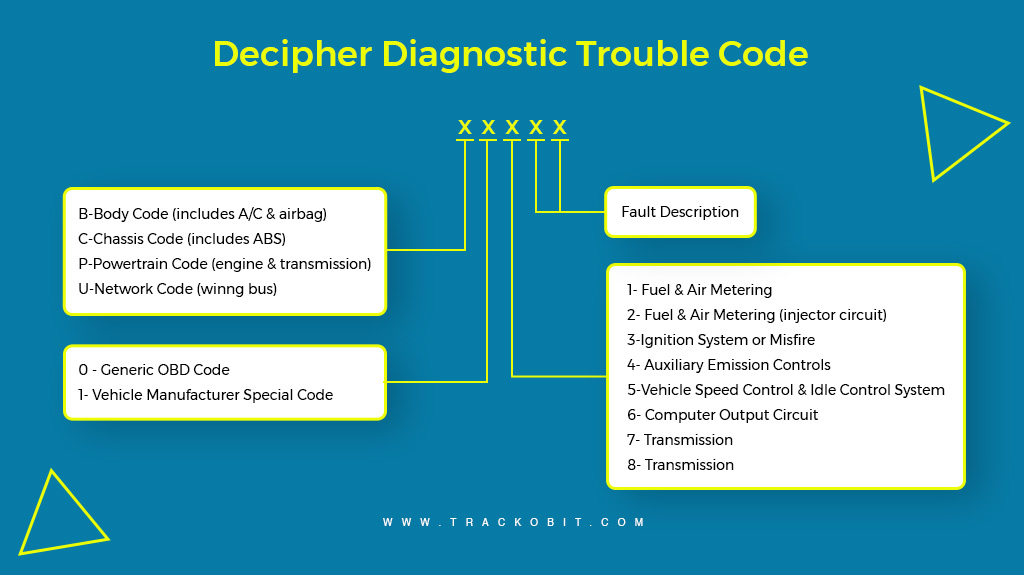

DTC codes are five characters long, starting with a letter that indicates the overall problem area of the malfunction:

DTC Formats

1. Each code starts with a letter that indicates the overall problem area of the malfunction:

- P – Powertrain, which includes the engine, transmission, and fuel systems

- C – Chassis, which includes steering, suspension, and brakes

- B – Body, which includes systems inside the vehicle, such as A/C

- U – Network, which includes all onboard computer systems

2. The second letter of the DTC code indicates whether or not the code is standard or manufacturer-specific.

- 0 indicates a standard code across all vehicles

- 1, 2, or 3 indicates a manufacturer-specific code, with 2 and 3 relatively rare occurrences

3. The third letter determines the subsystem:

- 1 or 2 indicates an issue with fuel or air metering

- 3 indicates an issue with the ignition

- 4 indicates an issue with the emissions system

- 5 indicates an issue with vehicle control or speed

- 6 indicates an issue with computer circuitry

- 7 and 8 indicate issues with the transmission

4. The fourth and fifth letters in the code are read together as two-digit numbers. So if you see a code that says P0246, you would read it as P-0-2-46. This allows you to pinpoint the specific problem in your vehicle, indicating the system and subsystem to inspect and identify the root cause.

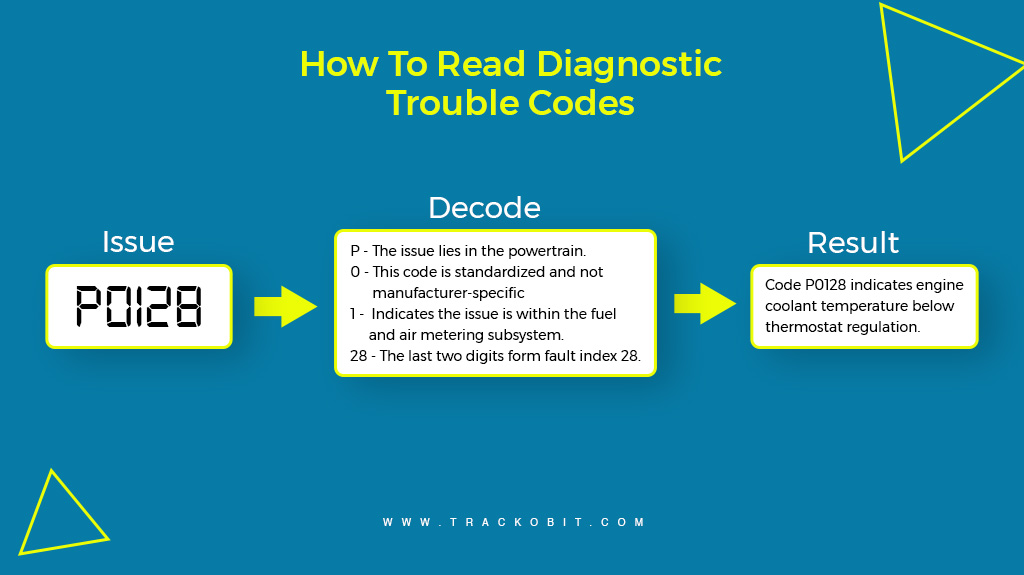

Let’s say you receive a notification on your fleet management system that one of your vehicles triggered the DTC code P0300:

The letter P immediately tells you something is wrong with the engine, transmission, or fuel.

- 0 means it’s a standard DTC code

- 3 identifies the ignition as the issue

- 00 refers to the cylinders.

What are Common DTCs?

Certain DTCs are more likely to appear than others. Below is a list of common DTCs and their corresponding malfunctions.

- P0442: A minor leak in a vehicle’s evaporative emission control system.

- P0606: A problem with the engine control module (ECM), sometimes called the power train control module (PCM).

- P0101: A malfunction in the circuit or mass airflow (MAF) sensor.

- P0110: An issue with the circuit of the intake air temperature sensor.

- P0500: A vehicle speed sensor malfunction.

- P0706: A fault in the sensor circuit range’s transmission range

Disclaimer – It is important to note that while DTCs are useful in identifying a vehicle’s malfunction, they are not a way to decipher why the malfunction occurred. A vehicle needs to be further diagnosed by a mechanic to identify and address the cause of the issue.

How Diagnostic Trouble Codes (DTCs) Work

Whenever your vehicle experiences a problem or detects a fault, its OBD system generates a DTC code.

Once detected, the OBD system will alert you by displaying the DTC code in visible warnings, such as an illuminated check engine light.

A DTC code lets external devices, such as an onboard diagnostics scanner (code reader), interact with your vehicle’s OBD system.

Initially, several versions of onboard diagnostics interfaces largely varied depending on the vehicle manufacturer.

But today, there are two main standards used to read DTC codes:

- OBD-II: OBD-II codes are used in light (6,000 to 10,000 lbs) and medium-duty vehicles (10,001 to 26,000 lbs). In US, all vehicles that were built and sold after January 1st, 1996 are required to follow this standard.

- J1939: J1939 codes are used in heavy-duty vehicles (26,001 to over 33,000 lbs) like city transit buses, refuse trucks, and cement trucks.

With the implementation of OBD-II, SAE created a standard DTC list full of common codes for every vehicle manufacturer. These codes help vehicles stick to emission regulations and save the environment.

When a vehicle’s check engine light turns on, a technician can plug a handheld OBD scanner into its diagnostic port (typically under the dashboard below the steering wheel column). Once connected, the scanner will display an error code.

Using an OBD scanner requires direct access to the vehicle in question. However, with the right telematics system, a fleet manager can receive real-time alerts anytime a vehicle generates a DTC code.

How To Read Diagnostic Trouble Codes (DTC)

Reading DTCs requires a scanner. This tool’s 16-point trapezoidal connector plugs into the vehicle and interprets the OBD code. Following these steps, you can access these codes with a scanner.

Step 1: Plug into the OBD port

A standard 16-pin diagnostic link connector (DLC) is used to access the onboard diagnostics of an OBDII-equipped vehicle. The OBD port is located differently in every car, although it’s usually under the dashboard on the driver’s side. The exact position should be listed in the owner’s manual.

Step 2: Turn on the ignition

The scanner is powered by turning on the ignition; you don’t need to start the engine over. If it is off when you turn on the ignition, check the connection between the scanner and the connector pins again. The ODB-II scanner shares a circuit with the auxiliary power outlet in the car, so try plugging something into it to see if it functions even if the connector is tight.

Step 3: Enter the necessary information

Since DTCs can be manufacturer-specific, some scanners require additional information. This could include the vehicle identification number (VIN), model, make, or engine type.

Step 4: Navigate the OBD codes

Your scanner might notify you of both pending and current codes. The issues that sets off your check engine light are called active codes. Pending codes are intermittent errors that must occur in consecutive warm-up cycles for the system to identify them as active. The code is cleared if the fault doesn’t resurface after 40 warm-up cycles.

Step 5: Interpreting the DTC

After obtaining the code, you can decipher its meaning. The details provided above will help you narrow down the nature of the issue. Still, you’ll likely need to utilize an app or visit a website that decodes the thousands of OBD codes and their meanings to obtain precise information.

How Do DTC Codes Help with Fleet Management?

Let’s say you have an outdated fleet telematics system that isn’t set up to deliver you the daily data your vehicles produce. If such is the case, you may have to depend on your drivers or field service technicians to notify your offices of DTC codes when they notice these warnings on the control panels of their vehicles. Alternatively, you may need to assign someone to physically check each vehicle regularly to ensure that all systems are functioning properly, as indicated by the instrument panels. These two procedures are not as effective as they could be.

A fleet-wide vehicle tracking system could gather and send this information to your business, enabling you to respond to DTC codes in your vehicles far faster and more reliably. The right GPS tracking software may help you increase your vehicles’ overall return on investment (ROI), decrease vehicle downtime, and maintain more dependable and effective fleet operations for your company and your fleet. It can also provide real-time problem codes to your fleet management team.

Conclusion

DTC codes are used to diagnose malfunctions in a vehicle. Sometimes, they can be minor, like a loose fuel cap, or more serious, like a faulty oxygen sensor. If your vehicle triggers an engine fault code, it’s important that you know what the DTC code means.

Handheld scanners can help you quickly identify the problem. However, if you manage a fleet of vehicles, using a telematics system like TrackoBit offers a better way to monitor diagnostic codes.

So what are you waiting for? Get our free demo already!

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.