-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

How Fleet Management Software Can Help Fight Hunger

- Author:Diksha Bhandari

- Read Time:6 min

- Published:

- Last Update: November 9, 2023

Table of Contents

Toggle

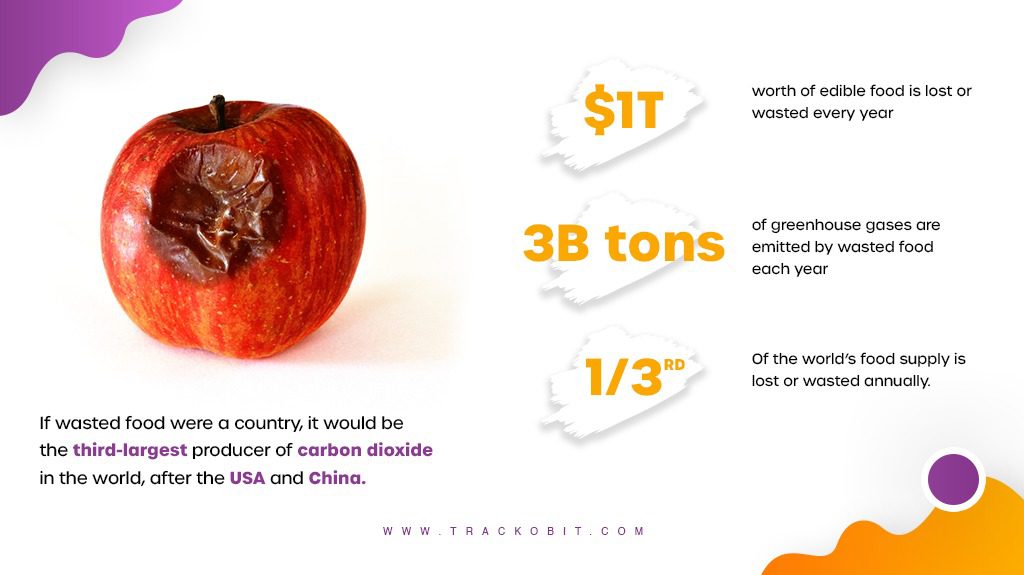

More than 800 million people sleep on empty stomachs around the globe. It’s more than 10% of the world’s population. Feeling privileged? Yes, we are. Here’s another interesting thing…

Table of Contents

Toggle

Do you know that 14% of food produced gets wasted in the post-harvest supply chain before reaching the retailers?

Shocking? Well, it is. A significant amount of food goes stale during transportation to the retail store.

Even the UN agrees that technology possesses the power to reduce food loss that can fill more than two billion bellies. Telematics and advanced fleet management software can play a significant role in saving the edibles that spoil during transportation from fields to retail shops.

Food For Thought

Can Telematics reduce people sleeping on empty stomachs?

The above-mentioned facts are enough food for thought because the problem is not with the amount of production but the management and the distribution of the produce. It’s about time that we fix the broken supply chain management infrastructure with the right technology.

This article is all about the challenges faced by logistics while moving food to retail destinations. How existing technology can help fix them at different levels.

It’s not just about organic vegetables and fruits anything perishable that has a relatively shorter shelf life requires technological aid to sustain logistical pressure.

First Thing First

What are perishable goods? Why do they need extra TLC?

Food such as bread, fruit, dairy products, etc. that perish in a short time come under perishable goods.

Their shorter shelf life is why they demand extra care and attention. They need to be transported from point A to B in a particular container, at a specific temperature, otherwise, they go stale.

The optimum range for each product or the kind of product is different. Hence, fleet managers have an added task to ensure the optimum temperature of vehicles other than just monitoring their whereabouts.

Fleet Management Software Helps Reduce Food Wastage

Fleet management software that comes with hi-tech temperature monitoring solutions is the cool-aunt that the food logistics sector needs to operate efficiently. The cold supply chain logistics have certain temperature categories for different sectors:

- -30°C TO -28°C Deep Freeze Category for seafood, meat export, etc.

- -20°C to -16°C is a Frozen category for frozen food, meat, etc.

- 2°C to 4°C come under Chill Category for vegetables, fruit, dairy, etc.

- 2°C to 8°C for Pharma Drugs – Medicines, vaccines, etc.

- 12°C to 14°C is the cool chain category for fresh produce, ready-to-cook food, etc.

If it wasn’t for the cold chain fleet management advancements, international export of most goods would not have been possible.

With the deteriorating quality of fruit, vegetables or any perishable good, its price value also reduces, leading to monetary losses at all levels. The margin of loss/profit keeps increasing as the quality of food increases and the distance the food has to travel to reach its destination.

Primary Cold Chain Transit Carrier Technology

Reefers – Refrigerated containers specialising in temperature-regulated logistics via multi-modal transportation are called reefers. They are powered by batteries or other forms of refrigeration.

Air Freights Containers – Air freight cold chain containers are suitable for small shipments that fit the confined space complying with airline freight norms.

Ice-Lined Refrigerators(ILR) – These are high-end insulated containers that have a lining of coolants that keep the inside cool even when the power is off.

TrackoBit is equipped with advanced solutions to ensure 100% compatibility with all sorts of cold chain carriers, cargoes and vehicles.

Cold Chain Monitoring Software Pruning Deficiencies

The food logistics sector is loaded with operational deficiencies across levels right from storage to transportation, to warehousing and retail. The scope of anomalies increases as the time and distance between the farm or manufacturing unit and the retail store increases.

So what’s the antidote?

Cold supply chain monitoring software does not only monitor the temperature but also helps regulate it remotely.

A temperature sensor collects data from the refrigeration system of the carrier. Now, GPS tracking software transfers the information fetched from the sensor to the software with the help of telematics.

Benefits of Temperature Monitoring Solutions

Just because you have signed up for a temperature monitoring solution with GPS Tracking software, doesn’t mean you do not get basic live tracking, geofencing, travel reports, etc. However, as far as the benefits of cold chain monitoring are concerned, they could play an imperative role in controlling food wastage. Let’s find out!

Real-time Temperature Alerts

Real-time temperature monitoring allows transparency into carriers inside the environment at all times. You get instant alerts as soon as the temperature drops/rises beyond the optimum range, enabling you to take quick action and save tons of edibles from rotting.

Actionable Insights and Reports

Live temperature updates are gold, and in-depth insights are a gold mine. Only who bother to dig deep extract the real treasure. The software automatically generates various reports on every fluctuation in temperature along with coordinates, speed and other relevant data to make well-informed business decisions.

Data Analysis

Data stimulates better decision-making and scalability. If the cold chain monitoring software offers you detailed analytics other than reports, you shall grab the deal instantly. TrackoBit understands the value of data and, therefore, provides a thorough analysis of your field force and their performance.

Temperature Monitoring Solutions Against Global Hunger

What are the benefits of opting for a complete fleet monitoring software system that also offers cold chain solutions?

Fleet management software as the name suggests is an end-to-end software solution for managing fleets. Solutions like temperature monitoring, fuel monitoring, route planning, etc. come as add-on solutions to the basic package. As far as features are concerned the list of basic ones is long. However, some features play a crucial role in cold chain monitoring. What are these let’s find out:

- ETA – Estimated Time Of Arrival

While the vehicle is out for delivery, managers can track the dynamic ETA considering the route being followed, estimated traffic and other factors. Managers can share it with the clients hence offering real-time updates.

- POD – Proof of Delivery

The consigner and consignee both worry about the shipment while it’s on the move as it’s their hard-earned money. PODs ensure the safe delivery of goods to the concerned consignee. You may opt for OTP-enabled, QR Code backed, e-signature or automatic PODs for timely delivery of goods.

They are like virtual boundaries that define an area that is either must or forbidden. Similarly, POI(Point of Interest) are crucial sports marked virtually on the map and assigned to vehicles when necessary.

- Route Deviation

Delayed deliveries are not acceptable in time-sensitive food logistics. Even a 30 min delay can cause mismanagement in the flow, causing a chain reaction of late deliveries. Therefore, check route deviations with real-time alerts.

A wrong turn or harsh braking can not only take a toll on the vehicle but also on the goods in the container. Imagine the amount of food wastage when the AC or the reefer is damaged by rash driving or a collision. Therefore, it’s imperative to keep an eye on the driving behaviour of drivers and train them if need be.

- Sensor Integration

Custom sensor integration allows fleet owners to install as many and whichever sensor they require for better monitoring such as door sensors, tyre pressure sensors and others.

Reap the Benefits of Cold Chain Monitoring Software to impede food wastage

Smart farming is on the rise but so is soil pollution as we have to fight the global problem of malnutrition. Instead of driving pressure on agriculture, it’s about time that we focus on the actual problem behind hunger and malnutrition which is food wastage. It will not be wrong to say that advanced cold chain monitoring can solve the biggest chunk of this problem.

Fleet owners can reap the benefits of fleet management software like TrackoBit to harness the true potential of telematics.

Diksha Bhandari is the Content Marketing Manager at TrackoBit. With over a decade of experience in the media and advertising industry, she has transitioned her expertise to the world of software and t... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.