-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Challenges of Operating the Supply Chain Industry

- Author:Drishti Dua

- Read Time:9 min

- Published:

- Last Update: February 3, 2025

Table of Contents

Toggle

The global supply chain can face several issues that when added up might lead to losses and bad productivity. With such a huge industry, this can have repercussions on the global economy. This is why it is important to understand and mitigate these challenges.

Table of Contents

Toggle

Research reports show that the global supply chain management industry currently stands at a huge sum of USD 28.9 billion in 2022. It is expected to reach USD 45.2 billion by the year 2027 with a CAGR of 9.4%.

As a highly competitive industry, businesses are constantly looking for ways to eliminate the issues their businesses face with the help of new technological innovations. In this blog, we will look at supply chain operations and the several challenges that are standing in the way towards development.

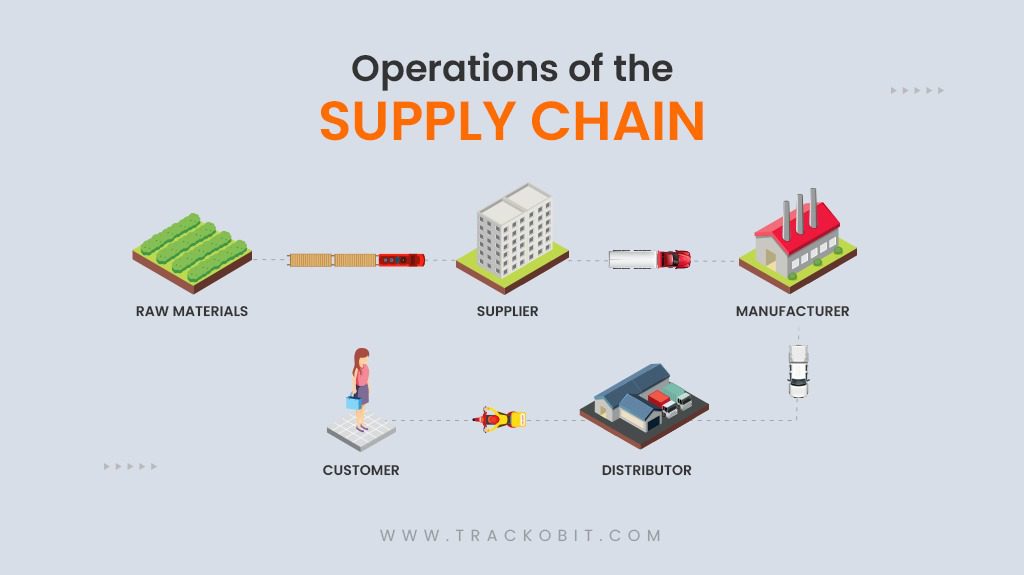

The Operations of the Supply Chain

Before we understand the ways in which a supply chain operates, let us look for a way to define this process. In simple words, the supply chain is a network that brings goods from the manufacturer to the customer. But while this process might sound linear, it actually has a lot more steps and interlinking.

To divide into major categories, the supply chain can be divided into the following steps:

- Collecting Raw Materials

- Processing in Factories

- Planning Inventory

- Packaging

- Transportation

- Customer Service

Each of these steps needs streamlining to ensure the smooth running of the entire supply chain. To understand this better, it is important that we see what challenges obstruct the supply chain operations at present.

Challenges that the Supply chain faces

The challenges that the supply chain is facing and actively trying to eliminate range from profitability to time inefficiency. Here are the top five issues that need urgent mitigation to ensure the growth of this sector:

-

Staffing Shortage

The lack of skilled and trained employees is a big issue that the supply chain is facing in recent times. To top this all off, the transportation leg of the supply chain itself has a shortage of drivers willing to step into the industry. They also lack the necessary knowledge of road safety which can be a hazard to any business’ safety and can also affect their productivity for the time period spent training these drivers.

A survey done by the government of the UK brought forth the issue that the supply chain currently lacks almost 90,000 to 100,000 drivers. Sounds like an intimidating stat when we talk about the fact that the transportation of goods is essential to elevate the supply chain’s growth. Without proper transportation, the supply chain will remain a hyperlocal transaction.

A recent real life example of broken transportation affecting the supply chain is during the pandemic. The lack of safe transportation methods led to a halt in long distance transportation. With only 2% of the total supply chain players claiming to be prepared for the pandemic-like conditions, the lack of preparation to tackle the issues brought on by workforce isolation is quite evident.

-

Port Capacity

It is said that the ports of a country are the indicators of their economic health. Well, it is safe to say that almost all the countries are not looking too good. Cost congestion is an issue that has been the bane of existence for several supply chain business owners. Not only do they affect the productivity of the supply chain, but can also lead to inventory mishandling.

Mismanagement at the port can lead to a rise in the ocean freight cost per unit of the goods being transported. With cargo ships now running at the capacity of almost 24,000 containers that take up to five days to unload, even minor inefficiencies can translate to major productivity loss and can also clog the port for other shipments.

To better understand this, imagine a domino chain where the slow unloading of even one shipment means disrupting the entire supply chain.

-

Rising Transportation Cost

The transportation costs of the supply chain have been on a constant rise. In the year 2022 itself, the hike has led to international transportation climbing from 8% to 12%. Considering the large scale of the supply chain, this rise in expenses can be the reason behind several businesses going under.

Rising transportation costs can be the result of several factors, some of which are:

- High Freight Cost: Due to the rising container shortage and the increase in consumer demands in the supply chain during the pandemic years, freight rates have also increased. This can lead to overloading vehicles as businesses try to cut down their need for more containers. Ultimately this practice harms the vehicles, leading to higher repair and maintenance costs.

- Bad Warehouse Network: In the current supply chain where international and interstate trade has become more common, relying on the process that is meant for domestic trade can lead to several kinds of inconsistencies, delaying the transportation process and forcing vehicles to cover long distances at a stretch. There needs to be better documentation of warehouses so that route planning can be simplified for the managers.

- Constant Route Deviation: Managers of the logistics industry often rely on planned routes that help businesses reduce their costs by eliminating bad roads and taking on paths with fewer tolls. But drivers that refuse adherence to these routes can lead to higher transportation costs.

- Split Shipment: It is more expensive to transport a complete order instead of splitting it into smaller shipments. This is because the fuel and labour force needed to make repeated trips in order to complete deliveries can add up to a big amount.

-

Material Scarcity

While production and processing can be the leading cause of material scarcity, several other factors can also be the reason for this issue. Some general supply chain challenges that can result in the mismanagement of materials are:

- Inaccurate Inventory Data

- Damaged Goods During Transit

- Shipment Misplacement

- Transportation Capacity Issues

- Shipping Delays

We mentioned above that inconsistency during a step in the supply chain can end up disrupting the entire process. Similarly, material scarcity can affect the steps that come after transportation. Customer relations take a major hit because of material scarcity and lack of management leading to lost or damaged orders as well.

-

Lack of Visibility

Managers not having any insights into their business operations is one of the leading causes of the supply chain’s challenges. This issue stems from a company losing monetary resources, and can affect their productivity, disrupting the entire supply chain. Some ways businesses lose sight of their operations include:

- Lacking Communications: Operational interruptions can be very damaging to the supply chain’s profitability. For example, suppose a vehicle breaks down in the middle of transporting raw materials. If managers are not informed of this breakdown in time, it can delay the following manufacturing or assembling operations.

- Inaccurate Data: Not having correct insights into your business operations can be another way that businesses might face transparency challenges. The source of eliminating pain points from a business is by studying the data that managers have on their ongoing functions. Without data, an optimisation strategy has no foundation to stand on.

Ways to mitigate supply chain challenges via Automation

Investing in automation software can be a game changer for fleet businesses responsible for the transportation leg of the supply chain. A fleet management system can regulate and optimise the system to become error free and efficient.

But how?

Here are some solutions that help fleet businesses tackle the challenges of the supply chain:

-

Route Planning Solutions

Route planning solutions aim to simplify fleet operations before vehicles embark on their task. This happens via a series of features:

- Trip Creation: The routes that managers create can also be based on the warehouse network that the managers have, making the best use of their existing resources. For multiple orders to be delivered in the same area, using the system to create multi-stop routes is the best call. It will help businesses save the money and time previously wasted on repetitive trips to the same area.

- Proof Of Delivery: Using the fleet management software, managers can ensure that their consignments are delivered with care. Thus, reducing any chance of damaging or theft of the cargo. The shared OTP, collecting e-signature, geoverified POD are all ways that ensure both accurate and timely task completion.

- Estimated Time of Arrival: When coordinating with customers for transportation tasks, it is best to share the vehicle’s ETA. This means that they can use this time frame to schedule their crew meant to unload/load the vehicle with goods. The trend of using time slots for warehouse management can benefit from this system, reducing any kind of chaos.

- Geofence/POI: Managers get to create a virtual boundary around any area. The system alerts them every time their vehicle enters or exits this boundary. They can use this feature to mark all the important areas on a route, or for dangerous areas as well. This boosts the visibility between the managers and drivers, staying updated with their driver’s location and ensuring safety.

For issues like rising transportation costs, route planning solutions can be very convenient to integrate and use. Managers can cut down on the causes behind high operation costs with the help of automation. While facing port capacity issues, features like ETAs ensure better time management.

Read Blog – Role of Route Planning in Logistics

-

Reports and Insights Generation

The best way for managers to tackle visibility related issues is by shifting to a telematics system. This system collects and communicates information with managers, highlighting any shortcomings during operations. Having access to this data can ensure that the optimisation strategies that the system adopts are not generic, but instead made to tackle the issues that fleets face.

For example, imagine the vehicles running are taking more time than necessary to reach their destinations, managers can consult the reports to know the reason. The reason turns out to be the constant traffic congestion on the routes that vehicles are travelling through. Thus managers can ensure that they try to find alternative routes for their drivers to travel through, with better traffic conditions.

The analytical dashboard makes access to data and insight a lot easier for managers. They can also download the reports fleet management software generates to promote studying data over a longer period of time. This helps pinpoint any recurring issues the system faces and find a permanent solution.

-

Hardware Integration

Using a customisable system comes with several perks, one of them being that you get to choose the hardware integration with your system. This makes the tracking and data collection processes simpler and error proof. Some hardware integration that can help fleet businesses take on supply chain challenges are:

- GPS tracker: The system can help managers track the real time location of both their vehicles and their consignments. Thus, there is no chance of theft, even during parking mode. It also streamlines the communication between managers and drivers, reducing any distractions drivers might face trying to contact managers while driving.

- Sensors: Sensors make telematics a lot more efficient. They can help fleet businesses collect more data which makes the management process a lot easier than when done manually. Some of the common sensors used in the supply chain include load sensors to avoid overloading vehicles, thermometers for cold chain transportation and so on.

- Emergency Button: There is no way for managers to predict the hurdles that drivers might face while on the road. This is why it is so important that they have the means to communicate with managers quickly. The SOS button makes this easier, just a click alerting managers of any emergency or dangerous situation.

Parting Words

The supply chain makes up a significant chunk of the global economy. Because of this the issues they face also end up with adverse effects on the entire world. While automation in all the steps of the supply chain can be beneficial, it is especially necessary to make sure that transportation is error free. Thus, fleet management software becomes an important investment.

This system can help fleet owners streamline their operations and also make sure that managers do not have to struggle to collect data of any kind. With actionable insights and analytics, training drivers to be more efficient and productive is child’s play.

“Efficiency is doing better what is already being done.” – Peter Drucker

After all, while fleet operations remain the same, it is their execution that makes all the difference!

Drishti Dua, a Content Contributor at TrackoBit has a rich background in literature and professional expertise in SaaS and technology writing. She has carved her niche in the space of Geospatial techn... Read More

Related Blogs

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.