-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Infographics

Explore key topics through visually impactful infographics.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Cold-Chain Supply for Better Vaccination Transportation

- Author:Ayushi Nagalia

- Read Time:3 min

- Published:

- Last Update: November 22, 2023

Table of Contents

Toggle

We are aware of the importance of everyone getting vaccinated against Covid-19 and that about 32.3% Indians are fully vaccinated till now.

Table of Contents

Toggle

However, have you ever wondered how these vaccines get to the vaccination centers?

Several products such as meat, fresh flowers, ice-cream, and vaccines need strict temperature regulation throughout the supply chain. Therefore, to transport them, you need to create and be aware of cold-chain supply and its management.

What is Cold-Chain Supply?

The wide cold-chain supply begins when the product is dispatched from the manufacturer and ends when the consumer receives it. It carries products that need to be transported and supplied at optimal temperature ranges. Any variations on the temperature front and the product is likely to either lose its potency or value.

Cold-chain supply management doesn’t only require temperature regulation within the vehicles but also efficient fleet management. Otherwise, even though the products might stay fresh, their delivery might not be plausible if it is too expensive or late.

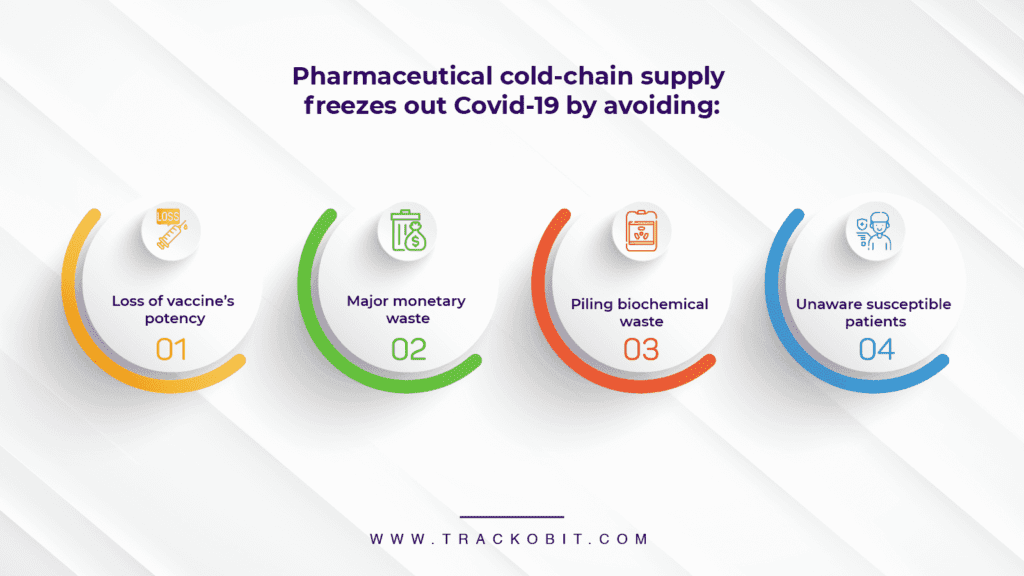

Implications of Failed Pharmaceutical Cold-Chain Management?

Pharmaceutical companies develop vaccines and other medications that require strict temperature regulation until administration. The results of failure in maintaining the optimum temperature ranges are troublesome for various manufacturing and consumer levels.

For example, any temperature fluctuates during the supply of a vaccine meant to be stored at a 2° to 8°C will tamper with its potency.

Here are a couple of implications of bad cold-chain supply management for medical transportation:

- Loss of Potency: Most biomedical formulas degrade due to disparity in the suggested temperature range. Such degradation leads to loss of potency which cannot be regained once lost.

- Monetary Waste: A lot of money goes to vaccine development and supply. When the cold-chain supply is not adequate and leads to loss in potency, it costs the manufacturer significant numbers.

- Susceptible Patients: Most end-users will not be aware of the loss of potency in a vaccine. Therefore, people might get ineffective vaccines and believe they’re immune while they aren’t.

- Increased Biowaste: Biowaste is generated in terms of chemicals and materials utilized in producing vaccines that lose potency later and also in terms of dumping at vaccination centers.

Vaccine Cold-Chain Supply Logistics Challenges

Cold-chain supply comes with some specific challenges in the pharmaceutical sector. These challenges are deeper than delays and temperature regulation and might pose all the above-mentioned threats.

- Limited Space Requirement: Vaccines do not take up a lot of space. Therefore, vehicles run with half the consignment they can carry, leading to extra running costs.

- Expense Management: Cold chain supply comes with extra expenses over the basic fleet management budget for temperature regulation in specialized vehicles.

- Tracking Temperature Fluctuations: Tracking temperature fluctuations manually is almost impossible for drivers, risking ruining consignment on the run.

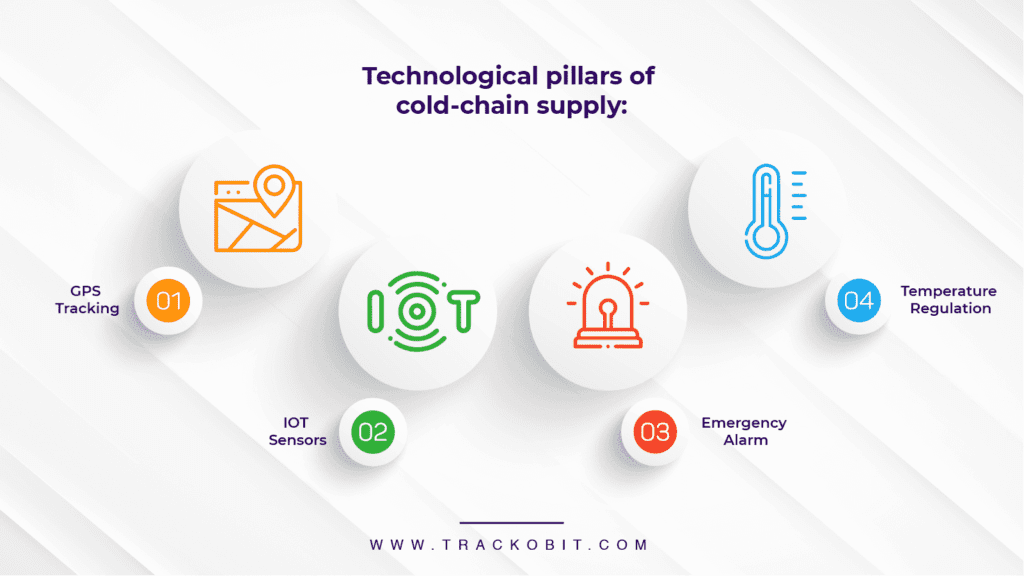

How Technology Helps Overcome Cold-Chain Logistics Challenges

Modern technology can help you preserve vaccines while also facilitating money and waste management. Here are a few ways in which IoT, ML, and AI can together aid cold-chain management in a beneficial manner to make vaccines available for a larger demographic.

- GPS Tracking: By utilizing effective fleet management software, you can constantly keep tabs on where your supply vehicle is. By doing so, you can ready the next step of the supply chain and also get exact ETAs for vaccine arrivals.

- IoT Sensors: Software integration with IoT sensors such as cabin thermometers save several vaccines from degrading during transportation. They allow fleet managers to keep track of the temperature within the vehicle to avoid potency loss.

- Emergency Actions: When sensors track any temperature fluctuation, ML can automatically decrease cabin temperature or send alerts to help save the consignment.

- Auto-Regulation: Through wired and unwired sensors, a steady temperature can be maintained automatically and fleet managers can know when the cabin’s doors were opened or closed.

Cold-chain supply is an advanced discipline on its own in the world of logistics. Understanding, regulating, and managing each level in the supply chain is crucial to maintain product quality and consumer satisfaction. You should use fleet management software such as TrackoBit that comes with flexible IoT sensor integration for effective supply management.

Ayushi Nagalia is a Senior Content Specialist at TrackoBit. She is a marketing maverick with a lush background in literature. With years of experience crafting content for various niches, she speciali... Read More

Related Blog

-

How GPS Resellers in the USA Grow Recurring Revenue with White-Label Fleet Software?

Anvesha Pandey 3 July 2025Are you a GPS reseller in the USA? Learn how to ditch one-time sales and build a recurring revenue empire with white-label fleet software.

-

9 Things System Integrators Look for in a Vehicle Tracking Software

Anvesha Pandey 27 June 2025Searching for client-ready vehicle tracking software? Explore 9 must-have features system integrators swear by, and how TrackoBit fits the bill.

-

Comparing GPS Tracking Solutions in Mexico: What Makes TrackoBit Stand Out

Anvesha Pandey 23 June 2025Operating a fleet in Mexico and unsure which software to choose? This guide offers a detailed comparison to help you pick the right fit for your business.

-

How Mexican Leasing Companies Track Fleet Usage & Misuse with Video Telematics?

Anvesha Pandey 16 June 2025Struggling with asset misuse and low utilisation in Mexico’s vehicle leasing business? Here are several ways that video telematics and GPS software may revolutionize accountability, control, and tracking.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.