-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Cost of Fleet Management: A Detailed Analysis

- Author:Tithi Agarwal

- Read Time:9 min

- Published:

- Last Update: July 10, 2024

Table of Contents

Toggle

A lot goes into owning and operating a fleet, and money is surely one of them. If you are looking for ways to reduce the cost of fleet management, here is a breakdown of the costs involved and areas where expenses can be curbed.

Table of Contents

Toggle

Maintaining on-schedule movement of vehicles on the road and allocating driver shifts optimally are only two out of many aspects of fleet management. Organizations using a fleet to carry out operations must perform a comprehensive fleet management cost study. They should ask themselves some money concerning questions like:

- What amount of trucks or vehicles should be sufficient to own? Employing how many drivers would be enough to avoid an over-exceeding budget?

- How much would the cost of vehicle upkeep and repairs be worth the spend?

For businesses with small fleets, figuring out answers to these questions is challenging enough. Conversely, things get really complicated when you have a massive fleet and a team to match. For this reason, controlling and optimizing fleet expenses is essential.

It’s also important to note that the fleet management industry is expanding quickly, with projections indicating a $300 billion market by 2034. This data reflects a very great time to get a fix for some cost-related decisions before competition becomes fierce.

So, what is fleet management cost analysis, and what are some of its essential aspects? Let’s break it down for you.

What are Fleet Management Costs?

Before we move any further, let’s answer the primary question first.

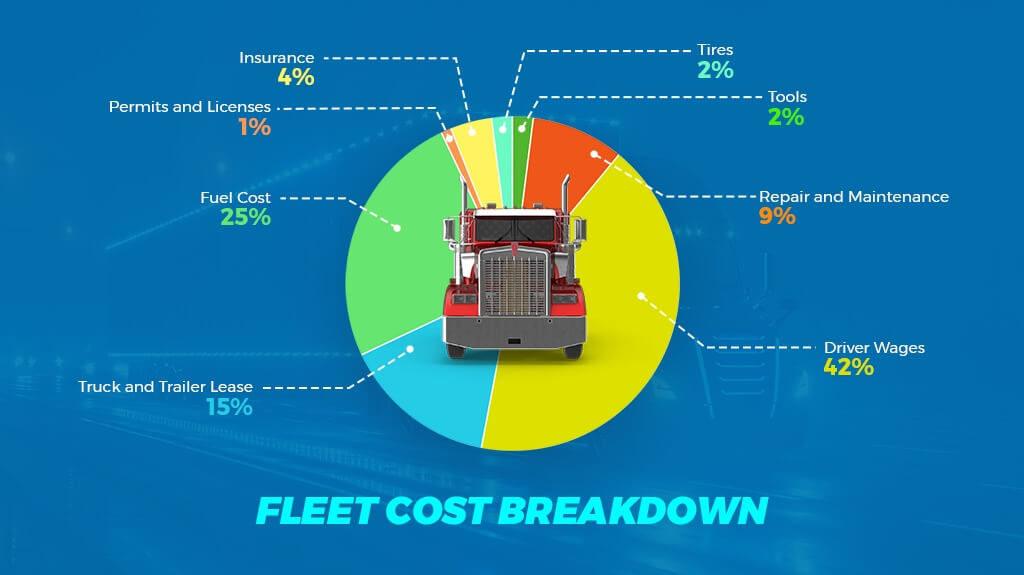

Fleet management costs mean the money you spend on maintaining and managing a fleet of vehicles. These usually include the following:

- The major costs are fuel, operational costs, driver salaries, and equipment.

- Cost of deploying modern tracking technology, such as GPS or telematics. Can’t replace these technologies as they help replan routes, minimize fuel costs, reduce wear and tear, and more.

- Administrative costs, such as taxes, insurance, and vehicle registration.

Add all of these up, and you are looking at a hefty bill. That’s where fleet management cost analysis comes to the rescue. Let’s discuss the mechanisms of fleet management costs that can alleviate your financial burden.

Understanding Fleet Management Costs

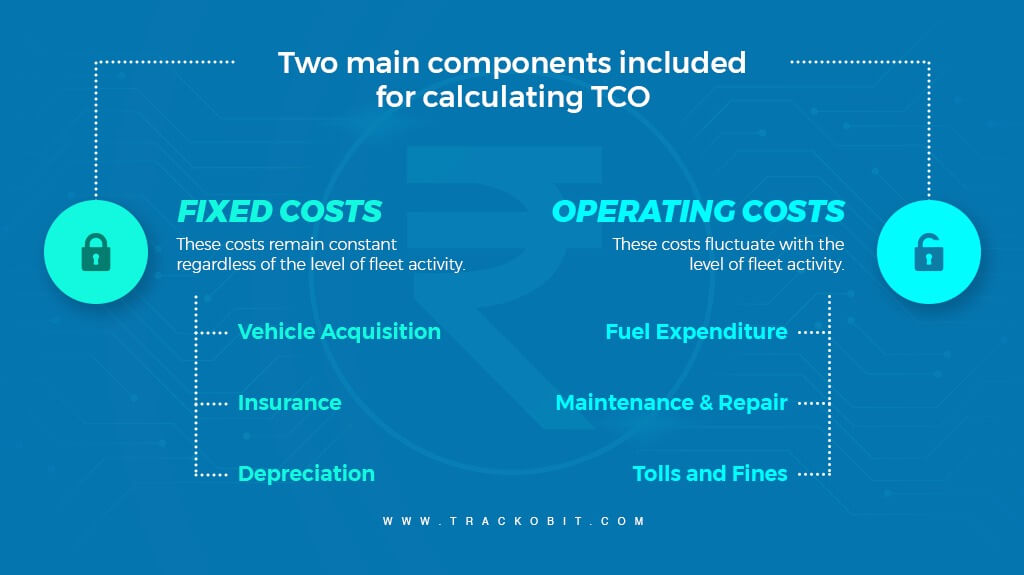

Any company that owns a small to large fleet must comprehend the complexities of fleet management operational costs. Everything affects the fleet’s operating effectiveness and financial stability, from insurance and depreciation to fuel and maintenance. There are two types of costs in fleet management – Fixed cost and variable cost.

1. Fixed Costs in Fleet Management

One of the unique qualities of fixed costs is their predictability. Fixed expenses stay mostly constant, unlike variable costs that tend to change This stability in cost enables businesses to do more accurate financial planning and budgeting. Because of this predictability, fleet managers are better able to allocate resources efficiently, reduce financial risk, and decide on fleet optimisation or expansion strategies.

Here’s how fixed costs in fleet management are ascertained.

-

Buying or Leasing Vehicles

Purchasing or renting a vehicle is the main source of fixed costs. These payments, whether made through outright purchase or leasing, comprise a sizeable amount of the fixed cost structure. Acquisition costs for vehicles include the purchase price up front and the financing charges if loans are required. In contrast, leasing agreements provide fleet managers with flexibility by requiring monthly payments over a defined length of time.

-

Insurance Premiums

Premiums for insurance are another essential part of fixed expenditures. Sufficient coverage for the drivers and the fleet is crucial to reducing risks and protecting property. Insurance costs contribute to the steady financial demands of fleet management, even if they may differ depending on variables, including vehicle type, driving history, and coverage options.

-

Depreciation

Even though it’s sometimes disregarded, depreciation is essential to fixed costs. Vehicles lose value over time as they age and accrue miles. Depreciation affects the fleet’s financial stability over the long run, even though it may not result in immediate cash outflows like other fixed costs do. Depreciation must be understood and considered to determine the true cost of fleet ownership versus leasing.

Let’s discuss variable costs in fleet management that are never fixed.

2. Variable Costs in Fleet Management

The fluid expenses that fluctuate in response to fleet activity and outside variables are known as variable costs. Variable costs are affected directly by variables like gasoline use, vehicle usage, and unanticipated accidents, contrasting fixed costs that never change.

Here is a detailed classification of variable costs in fleet management.

-

Fuel Expenditure

Fuel is one of the most significant variable expenditures in fleet management. Fuel costs, which are essential to fleet operations, vary according to several variables, including driving conditions, vehicle miles, and—perhaps most importantly—fuel prices. The erratic nature of fuel prices emphasizes how crucial it is to plan routes effectively, train drivers, and use efficient fuel management software technologies to reduce the overall cost of fuel for fleet operations.

-

Maintenance and Repairs

Another major variable cost component is maintenance and repairs. Routine maintenance is necessary to guarantee the dependability and longevity of fleet vehicles. This includes tyre rotations, brake inspections, and oil changes.

However, unexpected expenses might occur from accidents or unforeseen failures, adding unpredictability to maintenance costs. Managing maintenance-related variable costs requires implementing preventive maintenance schedules, performing thorough vehicle inspections, and encouraging a proactive vehicle care culture.

-

Tolls & Taxes

Tolls represent a variable expense incurred based on the routes taken by fleet vehicles. Whether traversing toll roads, bridges, or tunnels, toll charges can accumulate quickly, especially for fleets operating in densely populated urban areas or regions with extensive toll infrastructure. Effective route planning can help minimize toll expenses and optimize fleet efficiency.

-

Fines

Fines are an unavoidable variable cost that fleet managers must deal with, even when undesired. Administrative errors, regulations non-compliance, and driver errors can result in traffic violations, parking citations, and other penalties. Although the severity and frequency of fines might differ, they are an unpredictably high-cost component of fleet management. In order to reduce the likelihood of penalties and related costs, it is imperative to prioritise driver education, encourage compliance with traffic regulations, and put strong monitoring and reporting mechanisms in place.

Fleet Management Cost Analysis – The Breakdown

Maintaining and controlling costs can be a significant challenge for a company managing a large fleet of vehicles. Implementing cost controls requires a systematic fleet analysis that works for your business. Fleet management software can help by offering real-time, accurate expense tracking. It identifies areas where you can save money and provides valuable insights into your fleet that can save your future costs.

The fleet management cost analysis usually revolves around two factors, namely Total Cost of Ownership (TCO) and Cost Per Mile (CPM), which we’ll discuss here.

1. Total Cost of Ownership (TCO)

Total cost of ownership is a critical component of any fleet management cost analysis. It deals with the actual cost of your fleet by calculating the difference between asset purchase prices and fleet management costs. TCO calculations can help companies adjust fleet sizes, optimize maintenance schedules, and decide the best vehicle replacement timing.

TCO = Initial cost – (Operation cost + Maintenance + Downtime + Production) – Remaining Value

Let’s unpack this formula:

- Initial cost: The upfront vehicle price, whether purchased or leased.

- Operation cost: Expenses for running the fleet, such as licensing, fuel usage, driver compensation, and vehicle administration.

- Maintenance: Recurring expenses to keep vehicles in good shape, including repairs, downtime, and upkeep.

- Production: How much revenue can the fleet generate?

- Remaining value: The depreciation in vehicle value due to age and wear.

Companies with smaller fleets are advised to use specific fleet data to calculate TCO. Using standard industry data to calculate TCO skews the results in these cases. Also, it does not paint an accurate picture of your fleet.

2. Cost Per Mile (CPM)

Cost Per Mile (CPM) calculates the expense of driving or operating the vehicles in the fleet Cost per mile is calculated as:

CPM = (Fixed expenses + Variable expenses) / Total number of miles traveled

This formula adds all the expenses, including fixed and variable, and divides them by the miles traveled to calculate CPM. Here’s how CPM evaluation done through fleet management software helps your company:

- Shows the financial efficiency of each vehicle.

- It helps analyze current routes.

- Shows how much cost is associated with vehicle usage.

- It helps drivers improve their performance.

Reducing Fleet Costs – A Practical Guide

Once you have performed a comprehensive fleet management cost analysis, it is time to consider how you can reduce those costs. It is arguably the most significant concern for fleet managers, so let’s address it.

1. Vehicle Selection and Maintenance

Choosing appropriate vehicles is the best approach to reducing expenses. Fleet managers should select vehicles that are ideal for the intended use and ensure they have all the necessary features. For example, a vehicle used in congested urban areas should be tiny and fuel-efficient rather than massive and fuel-guzzling.

Regular maintenance is also essential to reduce repairs and fuel use. Inspect your vehicles regularly to find problems before they require expensive repairs.

2. Fuel-efficient Driving Practices

Fuel consumption can be decreased by encouraging drivers to drive more fuel-efficiently. Some fuel-saving tips drivers can learn are maintaining a steady pace, braking and accelerating smoothly, and cutting down on idle time. Similarly, you should outfit vehicles with fuel-efficient accessories like cab extenders, chassis skirts, sleeper roof fairings, low-resistance tires, etc.

Most importantly, investing in video telematics solutions can be a one-time but best investment. It can help you spot inefficient driving events and driver behavior that are causing excessive fuel consumption.

3. Better Routing and Scheduling

Better scheduling and routing can considerably reduce fuel and maintenance costs. Fleet managers may now use sophisticated route planning technologies to plan the most effective routes. Additionally, GPS monitoring can give real-time fleet information that helps with route changes in an emergency.

4. Use Fleet Management Software

Thanks to sophisticated fleet management software that makes fleet vehicle scheduling and planning more effective, fleet managers now have far less work to do. By receiving real-time data on vehicle performance, fuel consumption, schedules, and maintenance, managers can identify areas where they can save money. For example, the software can determine if a vehicle’s poor performance requires repair or replacement.

Conclusion

As a fleet manager, keeping costs to a minimum is essential to the business’s overall success. The above fleet cost analysis will give you a complete overview of how much is being spent and where, allowing you to intervene early and make decisions to reduce costs in the future.

TrackoBit’s fleet management software cannot reduce fixed costs, but it can surely play a vital role in reducing operating costs. Its fuel monitoring solution and driver behavior monitoring software reduce the chances of accidents and monitor fuel usage.

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

5 Best Driver Behavior Monitoring Systems for 2026

Tithi Agarwal February 23, 2026Having the best driver behavior monitoring system is a necessity as it helps you ensure driver safety and optimize operational…

-

Why is Driver Drowsiness Detection System Important for Fleet Management?

Shemanti Ghosh February 4, 2026A driver drowsiness detection system is critical for fleet management. It helps prevent fatigue-related accidents and reduces operational risks through…

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.