-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Is Electric Vehicles (EVs) the Future of Last Mile Delivery?

- Author:Tithi Agarwal

- Read Time:7 min

- Published:

- Last Update: December 9, 2025

Table of Contents

Toggle

Adopting last mile delivery software makes your last mile delivery much more cost-effective and sustainable with EVS.

Table of Contents

Toggle

Electric vehicles (EVs) are rapidly becoming preferred among commercial fleets, especially in the last mile delivery sector. The prime reason is the advantages logistics companies can reap from EVs, unlike ICE vehicles which are leading to higher operational costs. Also, deciding to make this switch will lead to a green supply chain.

Sure, Electric Vehicles EVs have a lot of advantages attached to them, but managing them is no easy task, especially when combined with last-mile delivery. The last-mile delivery sector and EV industry are evolving and developing, driving the need for proper management and advanced technology. Therefore, opting for a last-mile delivery software well adjustable to EVs will be a great choice.

Switching To Electric Vehicles in Last-Mile Delivery

But why is it that last-mile delivery companies are switching to electric vehicles? One of the biggest concerns and challenges of last-mile delivery is the rising cost of operation. It is considered the most expensive part of the supply chain, as 53% of the budget goes into this last leg of the operations. But with EVs, companies can, with ease, bring down operational costs.

(Source)

Cost Reduction

Incorporating EVs in your last-mile delivery fleet is environmentally friendly and economically beneficial for companies. Since electric vehicles have no fuel usage, logistics companies don’t have to battle the rising fuel costs. There is a direct correlation between the amount of fuel consumed and the total cost of transportation.

This very fact is driving big brands like Walmart, Domino’s, and Amazon to use electric delivery vehicles. Through it, they will be able to curb the rising cost of operation without compromising on customer experience and reduce their carbon footprints too.

Reduced Need for Maintenance

Another way EVs are helping logistics companies save costs is through a relatably less need for maintenance than traditional ICE vehicles. This is because they don’t have many moving parts. And since they don’t have many moving parts, there is no wear and tear, because of which the requirement for maintenance is less.

Tax Benefits

More ways to enjoy monetary benefits by combining last-mile delivery and EVs is by relishing tax concessions and friendly laws the government is adopting and offering. In addition, they are doing so to encourage the adoption of electric vehicles.

Sustainability

Building on the previous point, governments encourage logistics companies to move towards a greener supply chain by electrifying them. Again, looking at the heightened carbon emissions, the government is adopting sustainability goals. For example, NITI Aayog’s Shoonya initiative aims to electrify the delivery fleet.

Brand Value

78% of India’s urban residents feel that last-mile delivery vehicles significantly contribute to air pollution. They all favor logistics companies switching to EVs as the first step in reducing carbon emissions. Companies are willing to transition to EVs to maintain brand value and imbibe corporate social responsibility.

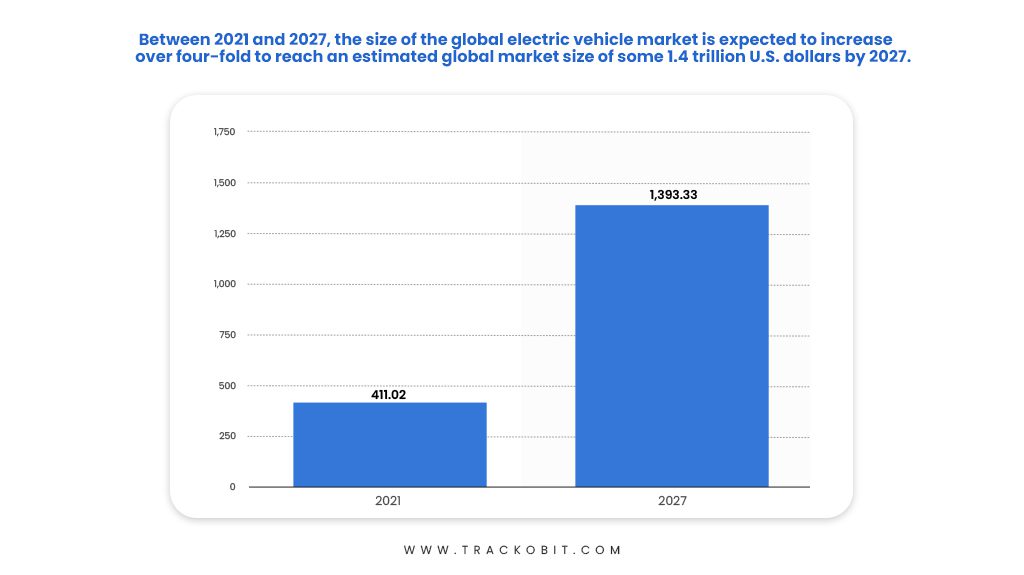

Size of Opportunity/Market

In recent years, we witnessed the rise of two markets, local deliveries, and electric vehicles, and Covid contributed to it majorly. Almost every company is aiming to electrify its last-mile carriers. This is because of the multiple benefits that they will get to reap. The initial cost of building the infrastructure might be high, but you can earn double of it in the long run.

Various companies have pledged to adopt EVs into their daily operations. For example, Swiggy has promised to cover eight lakh kilometers through EVs by 2025. Bigbaskst plans to transition into 90%of its fleet into electric vehicles by 2024. In addition, delivery giant Amazon has announced that it will add more than 10,000 EVs to its delivery fleet in India.

Use Case

As said by TrackoMile famously, “ You need it, we provide it.”

XYZ Logistics. Co. wants to incorporate EVs into its last-mile delivery operations because of their economic benefits. But the problem arises when the logistics company has to fully utilize the battery range of 80KM that an EV vehicle can go in one charging. They need solutions to help them utilize the restricted KMs, and the delivery agent shifts to increase the operation’s effectiveness.

The combined solution to tackle the challenges of last-mile and EVs, we suggest last-mile delivery software, offering solutions like BMS and route management, to name a few.

Task and Load Management

Smart planning is required when dealing with last-mile delivery and EVs. Since the weight of the load of the parcels might affect the charging of the electric vehicles, it is essential to assign the right vehicle for bigger parcels.

Similarly, delivery agents must be assigned schedules to cover maximum distance and deliver parcels on time. Last mile software offers automated task management and load management features which help to save effort and time wasted in trying to configure how to manage both.

Route Planning and Optimizing

Route planning is vital when managing EVs for last-mile deliveries because of their restricted travel range and the time required to charge for further use.

The system suggests an optimized path by considering various factors like charging/battery swapping stations, fastest/shortest route, route conditions, and traffic. This is also essential to avoid mid-route charging, which can be expensive.

Dynamic Dispatch

Dynamic Dispatch management comes into use when logistics companies have to handle huge volumes of orders. Also, the orders must reach their destination on time and as smoothly as possible. This has to be done considering the operation’s costs and duration. The solution presents you with available vehicles and a workforce to deliver orders. This makes scheduling and planning routes easier.

Rider Roster

Rider Roster will help the manager keep track of the riders and vehicles in use for different shifts. This becomes essential when the bikes are charging to avoid time wastage; other riders can use the charged vehicles. With it, you can schedule deliveries as per the availability of vehicles and riders and manage both without leaving any gaps. Thus balancing both independent variables to align their dependency.

This comes into use when logistics companies rent riders and EVs from other companies and pay rent or wages according to the time and kilometers covered by the rider and vehicles.

Carrier Capacity Management

To reduce the fulfillment burden, carrier capacity management presents you with the solution. Using it, the company can optimize its vehicle’s capacity. For example, if the company has only EV bikes, more trips will be required, but if it has a few mini trucks, order fulfillment will be rapid with a cost reduction.

Battery Management System (BMS)

Battery Management System is crucial when using EVs. It’s a system that manages the battery or cell of electric vehicles, thus ensuring their safety and maximum utilization. It is responsible for ensuring that the battery complies with the set parameters, collecting data, and ensuring the same voltage is distributed throughout the battery.

Functions of BMS are:

Monitoring Battery Function

It includes ensuring equal distribution of voltage throughout the cells, temperature maintenance, state of charge of the cell, and battery health.

Managing Thermal Health

Fluctuation in temperature is the most significant factor affecting the battery. The thermal management system keeps in check and controls the cell’s temperature, thus preventing loss of charging.

Making Key Calculations

The system calculates multiple battery values based on the set parameters. For example, the maximum charge and discharge current determine the cell’s charge and discharging speed.

Staff Manager App

The staff manager app allows managers to work and coordinate lucratively. In addition, the app displays all the required information to ensure the last-mile delivery’s success.

- The riders’ attendance helps to determine their presence on the field.

- Accurate live tracking helps to eliminate time theft or any unauthorized activity.

- Every bit of rider info is presented in one place.

- It has an inbuilt chat box for communicating essential details or changes in schedule to riders.

- Analytical reports can be viewed on the app, which helps determine the critical metrics of the last-mile delivery operation.

With the help of all these solutions, logistics companies can easily adopt and manage EVs in their delivery fleet. As a result, both disadvantages, like cost ineffectiveness and restricted kilometers, get eliminated.

Yes, EV is The Future of Last-Mile Delivery

There we said it – the future of last-mile logistics is EV. We say this after seeing the benefits electric vehicles have to offer. And with the help of last-mile delivery software, it can be easily integrated into the last leg of the supply chain. In fact, the software will help enhance the operation’s effectiveness.

TrackoMile is one such last-mile delivery software that allows logistics companies to manage both last-mile operations and EVs by offering technically rich solutions adaptable to EVs.

Click here to electrify your fleet!

Last Mile Delivery Software

Have everything done within seconds: order sorting, route optimisation, and dispatch planning.

Don’t believe us?

Tithi Agarwal is an established content marketing specialist with years of experience in Telematics and the SaaS domain. With a strong background in literature and industrial expertise in technical wr... Read More

Related Blogs

-

Top 9 Delivery Management Software in 2026

Tithi Agarwal February 2, 2026By choosing the best delivery management software, companies can benefit from features like route optimization, dispatch management, and more. This…

-

How Rider Tracking Software Improves Delivery Accuracy and Reduces Fraud

Tithi Agarwal December 8, 2025Rider tracking software improves delivery accuracy with real-time GPS visibility and automated ePOD. It also enables route optimisation and fraud…

-

Top Electronic Proof of Delivery (ePOD) Software in 2026

Tithi Agarwal September 25, 2025Electronic proof of delivery has become the backbone of modern logistics. Explore the top 8 ePOD software in 2026 and…

-

The Rise of Electric Fleets: Challenges and Opportunities for Businesses

Tithi Agarwal September 4, 2025The global fleet landscape is poised for a decade-long transformation. This change is being powered by electricity. Logistics-led businesses are…

Subscribe for weekly tips to supercharge your last-mile delivery.

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.