-

TrackoBit

Manage commercial vehicles with the new-age Fleet Management Software

TrackoBit -

TrackoField

Streamline your scattered workforce with Field Force Management Software

TrackoField -

Features Resources

-

Blog

Carefully curated articles to update you on industrial trends. -

White Paper

Insightful papers and analysis on essential subject matters. -

Glossary

Explore an alphabetical list of relevant industry terms. -

What’s New

Get TrackoBit & TrackoField monthly updates here. -

Case Study

Explore the cases we solved with our diverse solutions. -

Comparisons

Compare platforms, features, and pricing to find your best fit.

-

About Us

Get to know TrackoBit: our team, ethos, values, and vision. -

Careers

Join the most dynamic cult of coders, creatives and changemakers. -

Tech Support

Learn about our technical support team and services in detail. -

Events

Check out the exhibitions where we left our marks and conquered. -

Contact Us

Connect with us and let us know how we can be of service.

Optimizing the Milk Supply Chain From Farm to Fridge

- Author:Ayushi Nagalia

- Read Time:4 min

- Published:

- Last Update: December 16, 2025

Table of Contents

Toggle

Have you ever opened a carton of milk and were sure that it had gone bad? Milk can either be highly nutritious or a carrier of stomach infections, depending on the condition it reaches your gut.

Table of Contents

ToggleTherefore, consuming dairy products over the expiration date is always unadvisable.

Dairy products leaving from the farm need much more care and meticulous supply chain management than you’d think.

The quality of milk you’ll drink tomorrow depends on the dairy products’ supply chain. Therefore, to maintain the good in milk, you need to maintain the best in your fleet management system.

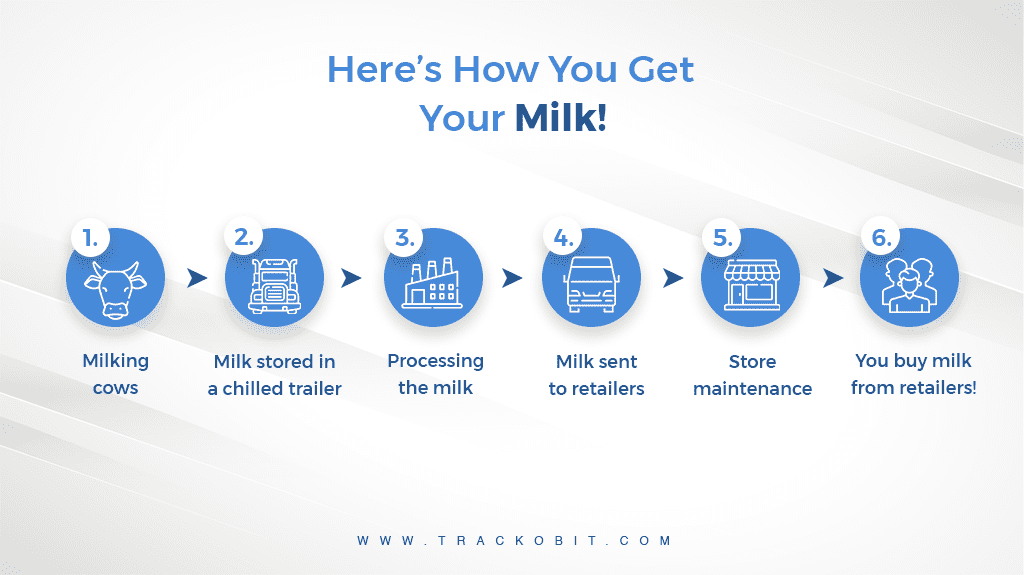

The Milk Supply Chain

To understand just how complex bringing milk from farm to fridge can be, you need to know what the daily dairy supply chain looks like.

The below-mentioned chain seems straightforward on paper. However, executing it safely, on time, and while maintaining freshness is the real challenge.

- Cows are milked at the dairy farm

- The milk is transported from the farm to a chilled trailer that has to maintain a temperature under 4.44°C.

- This trailer is transported to a facility where the milk is processed. Here, the milk is screened, homogenized, pasteurized, and packed.

- This pasteurized milk is then sent to retailers.

- The milk finally reaches the final customers from retailers.

The milk needs to reach stores within two days and should be consumed within the next two to three days. Maintaining specific conditions while transporting in such a short amount of time is what makes the dairy supply chain so complex yet interesting.

What Challenges Wait For Dairy Supply Chain Management?

Dairy transportation system comes with its own unique challenges. From milk getting spoiled due to bad temperature management to the chain getting delayed due to bad route planning, anything can happen!

To reduce the chances of such mistakes happening, let us oversee all the challenges you’re likely to face in the supply of dairy products without fleet management software.

- Raising Temperature: The storage trailer’s temperature shouldn’t rise over 4.44o C. In case it does, the catalyzed bacterial activity will ruin the milk much before than expected. Major fluctuations in temperature cannot be healthy for the milk’s quality either and hence needs to be avoided.

- Delayed Transportation: Dairy supply chain lifespan is so short that any delays can risk an entire batch going to waste. However, haphazard supply chain management can easily lead to delays and hence, loss and spoilage. Such loss can be too heavy for the manufacturer to bear.

- Rocky Roads: Milk packaging is generally not very strong. Therefore, regardless of how well they are kept together, rocky roads might make some of the packets tear or spill. Moreover, the rockier the roads, the more the possibility of delays in the supply chain.

- Uncertain Container Locations: With such a short life cycle, it is crucial for everyone involved in the supply chain to be aware of where each vehicle is. This can help in further storage and supply management.

- Expensive Operations: If the total operational cost of the milk supply chain increases, so will the cost of milk! And nobody wants that, right? However, with rising fuel prices and resource wastage, operation costs are very likely to rise unless everything is managed impeccably.

- Pilferage: Milk is a common commodity that might get stolen in small quantities by either driver themselves or anyone else. Since the cartons are small and numerous, missing out on loss through pilferage is common. When they calculate the cost of about 10 milk packs getting stolen every day, the price companies pay is huge.

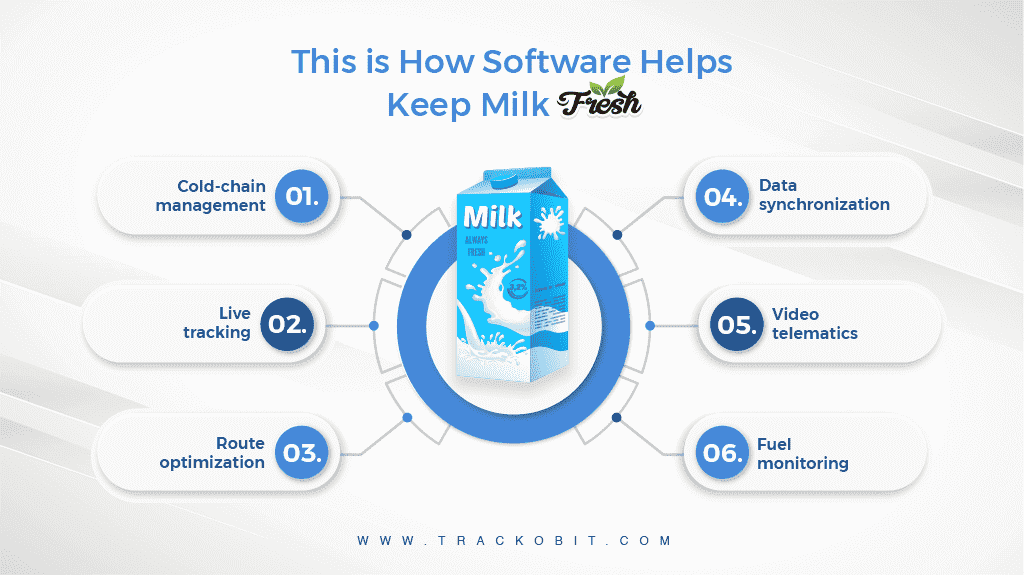

How Can GPS Tracking Software Help Keep Milk Fresh?

Now that you have a clear idea of most of the commonly faced issues with dairy supply, let us find some solutions. With a potent fleet management system, there is hardly any supply chain challenge that you cannot handle!

- Cold-chain Supply: With fleet management software, you can track the live temperature of the storage reefer. Potent software will also send you alerts if there are frequent temperature fluctuations or if it is about to rise above the recommended level.

- Live Tracking: The primary purpose of GPS tracking software is to show you where your vehicle is in real time. Therefore, now retailers will always know when their store is about to receive fresh stock of milk. You can also offer accurate ETAs through the software’s analytical predictions.

- Route Optimization: With fleet management systems, you can plan the least time and money-consuming route. Moreover, you can also optimize routes to avoid areas with high theft rates or broken and busy roads. Moreover, if drivers deviate from their route causing delays in deliveries, you will know immediately through software!

- Complete Data Sync: Most fleet management software allows you to tag trucks for the managers’ convenience. This way, you can mark which truck is carrying what lot to avoid all confusion altogether. This data sync is also helpful in managing driver logs and vehicle utilization.

- Video Telematics: Through video telematics, you can get insurance claims in case of accidents. You can supervise driving behaviour, and can also place a camera in the reefer to ensure that no milk package gets stolen. Through motion-sensing cameras, your software can alert you if it senses any unusual activity in the reefer.

- Fuel Monitoring: Since fuel is one of the biggest operational costs for any fleet, fuel monitoring will help cut down costs. You can get an idea of how much fuel your vehicles consume and optimize routes and maintenance accordingly. This way, everyone can get affordable milk every day!

Summing Up

Gone are the days when most people used to consume their milk fresh without much processing. Since even fodder today is not pure, there is no way people can consume milk without pasteurization and homogenization.

With the complexities unique to the dairy supply chain management, only technological help can allow people to receive drinkable and healthy milk. As a dairy supply chain manager, ensure using GPS tracking software that allows perfect fuel optimization, route planning, and cold-chain monitoring!

Ayushi Nagalia is a Senior Content Specialist at TrackoBit. She is a marketing maverick with a lush background in literature. With years of experience crafting content for various niches, she speciali... Read More

Related Blogs

-

When Tracking Needs a Clock: Rethinking Fleet Visibility

Tithi Agarwal December 24, 2025Read on to understand why fleet tracking works better when it follows working hours. Because visibility should support operations, not…

-

What Makes TrackoBit’s Video Telematics Software Truly Next-Gen?

Shemanti Ghosh December 17, 2025TrackoBit’s video telematics software blends smart video intelligence with full server control. The result? Superior fleet reliability and safety.

-

Plug, Pair, Perform TrackoBit Introduces BLE Sensor Integration

Tithi Agarwal November 26, 2025TrackoBit’s BLE Sensor Integration enables wireless, real-time monitoring with faster installs and accurate insights. It improves fleet efficiency, visibility, and…

-

How to Use Driver Behavior Reports as a Sales Hook to Close Big Fleets

Tithi Agarwal October 16, 2025TrackoBit’s driver behavior reports empower fleet providers to win big contracts by showcasing safety, efficiency, and measurable ROI.

Subscribe for weekly tips to optimize your fleet’s potential!

Your inbox awaits a welcome email. Stay tuned for the latest blog updates & expert insights.

"While you're here, dive into some more reads or grab quick bites from our social platforms!"Stay Updated on tech, telematics and mobility. Don't miss out on the latest in the industry.

We use cookies to enhance and personalize your browsing experience. By continuing to use our website, you agree to our Privacy Policy.